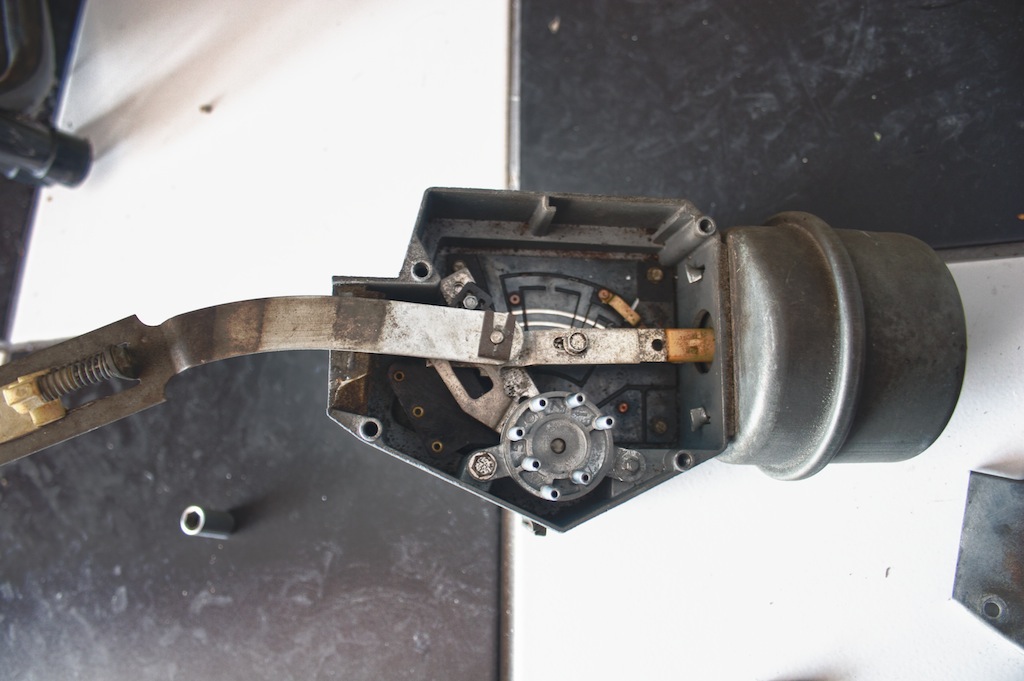

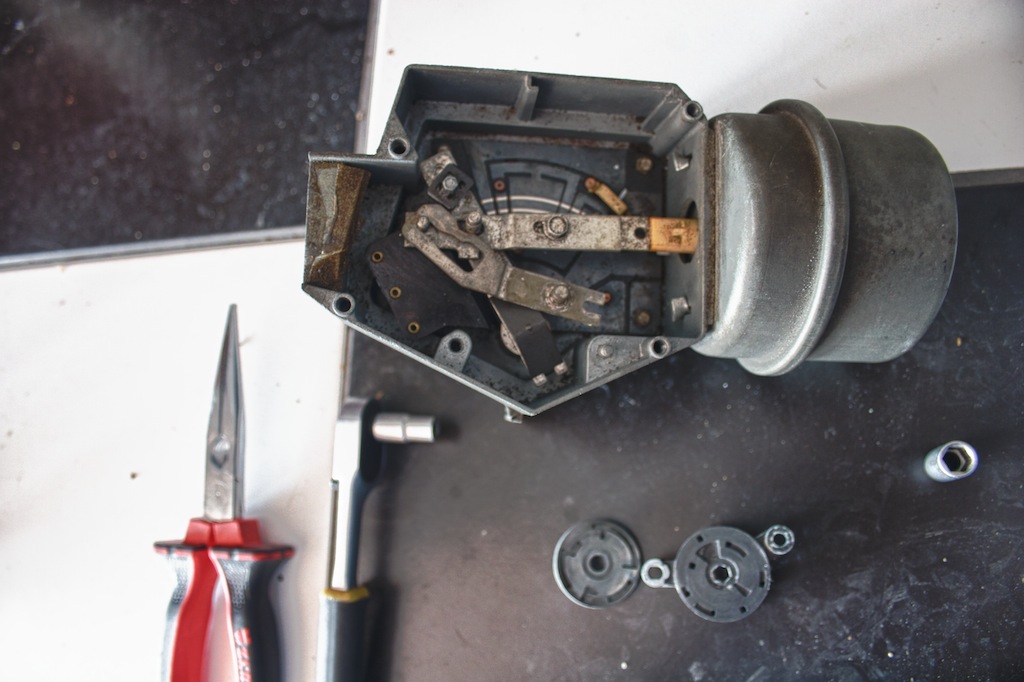

1966 AC BLOWER VACUUM MASTER SWITCH

I rebuilt the carburetor and let the car idle for a while. During this I wanted all accessories to move and also turned on the heat. It came on as always and after about 30sec the blower went off again. The power servo started to move in and out all the time by itself, but the blower would stay off. The idle speed up came on and off as well depending on the placement of the power servo. After a while it stopped doing this and stayed in the fully retracted position (full heat). If I turned the temperature dial it did not change anything - but it was around freezing outside and this is what it should, do as the sensors sense the low temperatures and then send the system into full heating mode.

I checked the following things.

- Master Switch seemed to work and gets engaged by vacuum. Power is going through it as it should. Current is going in and out. (This is what I thought…)

- Blower Motor tested with a direct feed - worked

- Blower Motor Relay - tested. Put a 12 V feed to the dark blue connector and it engaged and the blower motor came on. There was no current coming through the blue wire though.

- Power Servo - cleaned all contacts and measured the resistance in all positions - looked good to me

- Control Head in Dash - removed it and checked the blower switches - it seemed to work.

Full vacuum was applied to the power servo, and I also checked the vacuum and voltage at the transducer. I also checked all vacuum actuators with a vacuum gauge, but everything checked out perfectly.

I then put everything back together. Still the system did not work in the full heat position. I did a lot more tests and checked the vacuum and electrical diagrams.

I ordered the 1966 AC manual from "Cadillac Tim" which is available also on ebay for $45,- . These instructions are a must-have for your car, as everything about the AC system is explained very well by Tim. There is a great troubleshooting guide in there. Its money well spent! Tim also offers a rebuild service for many Cadillac parts and has a great selection of refurbished parts. Check out his website!

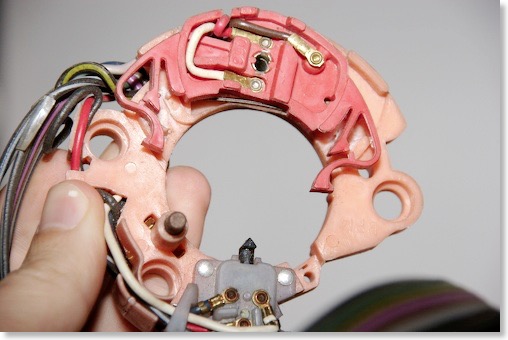

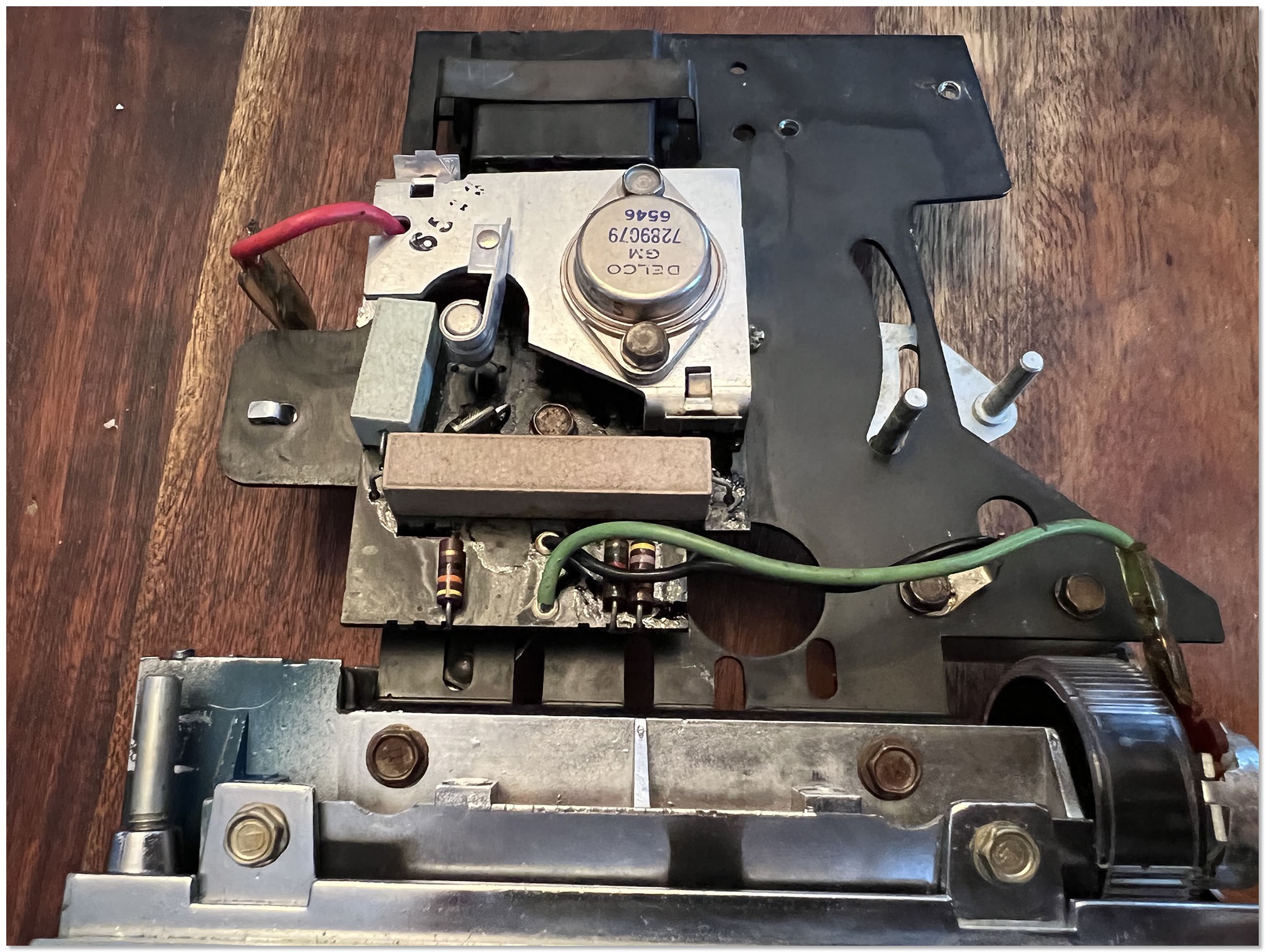

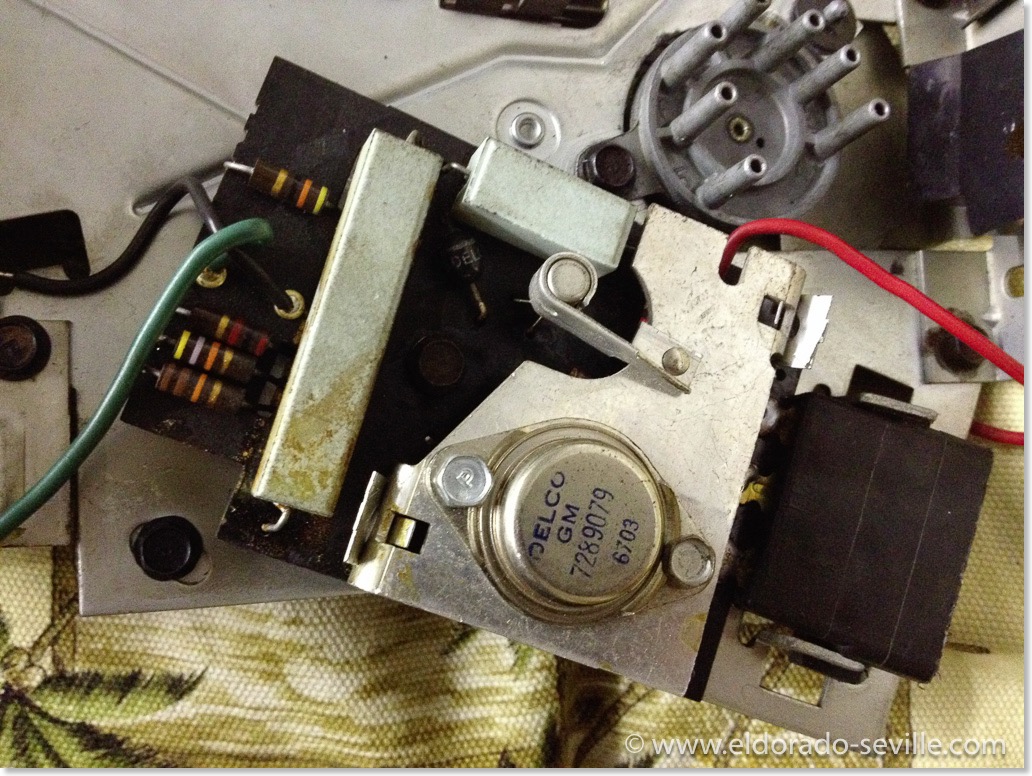

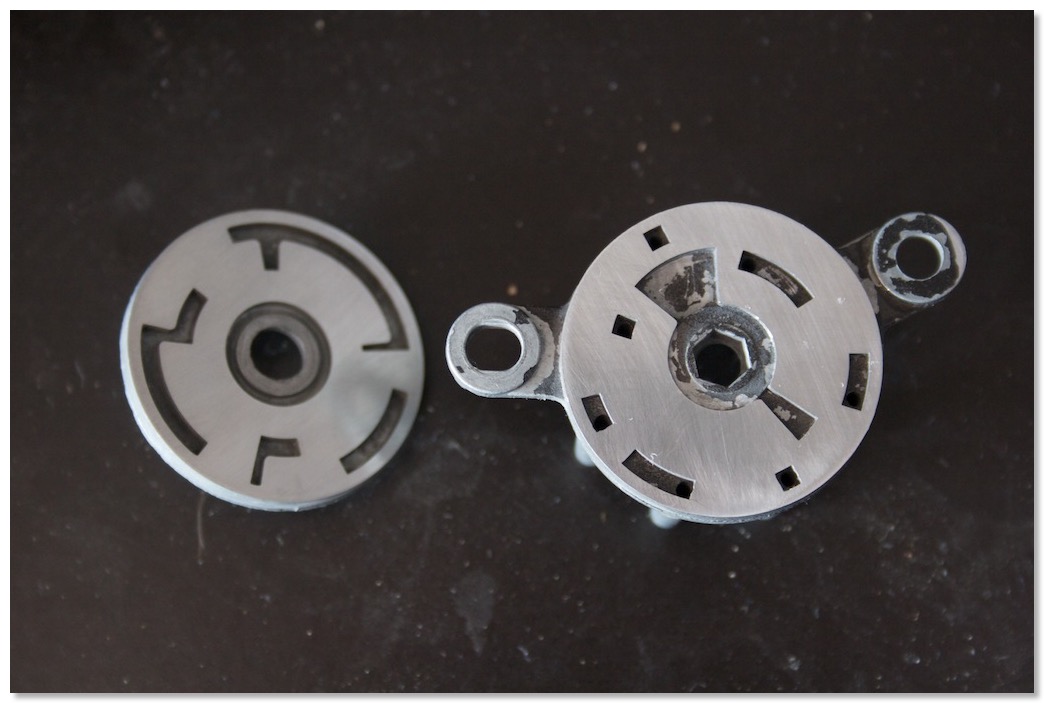

The 1966 dash control unit - here you can see the amplifier part.

After days of troubleshooting it finally dawned on me where the problem was. I had checked the master vacuum switch multiple times and when checked it always had electrical continuity. But I did not check it correctly. I only pushed the backside of the switch until I heard a click.

I should have tested it with full vacuum applied. As it turned out, if high vacuum was applied to the switch (during heating mode), the switch did no longer work correctly!

The contacts did no longer touch when full vacuum was applied to the switch…

The contacts did no longer touch when full vacuum was applied to the switch…

Today I took it apart and made a video about it. As it turned out the switch contacts did not align as they should and I had to bend it a little bit to make it work again. I then put everything back together and now the AC system works perfectly again. Check out the video for all the details!

REPAIRING THE FRONT DRUM BRAKE ADJUSTERS ON MY 67 DEVILLE

On the warmer side there was a slight brake drag while on the other side the wheel spun completely freely.

I did not notice any problem while braking and had the impression that the brakes worked evenly as the car did not pull in any direction.

When I now opened up the brakes…

READ MORE!

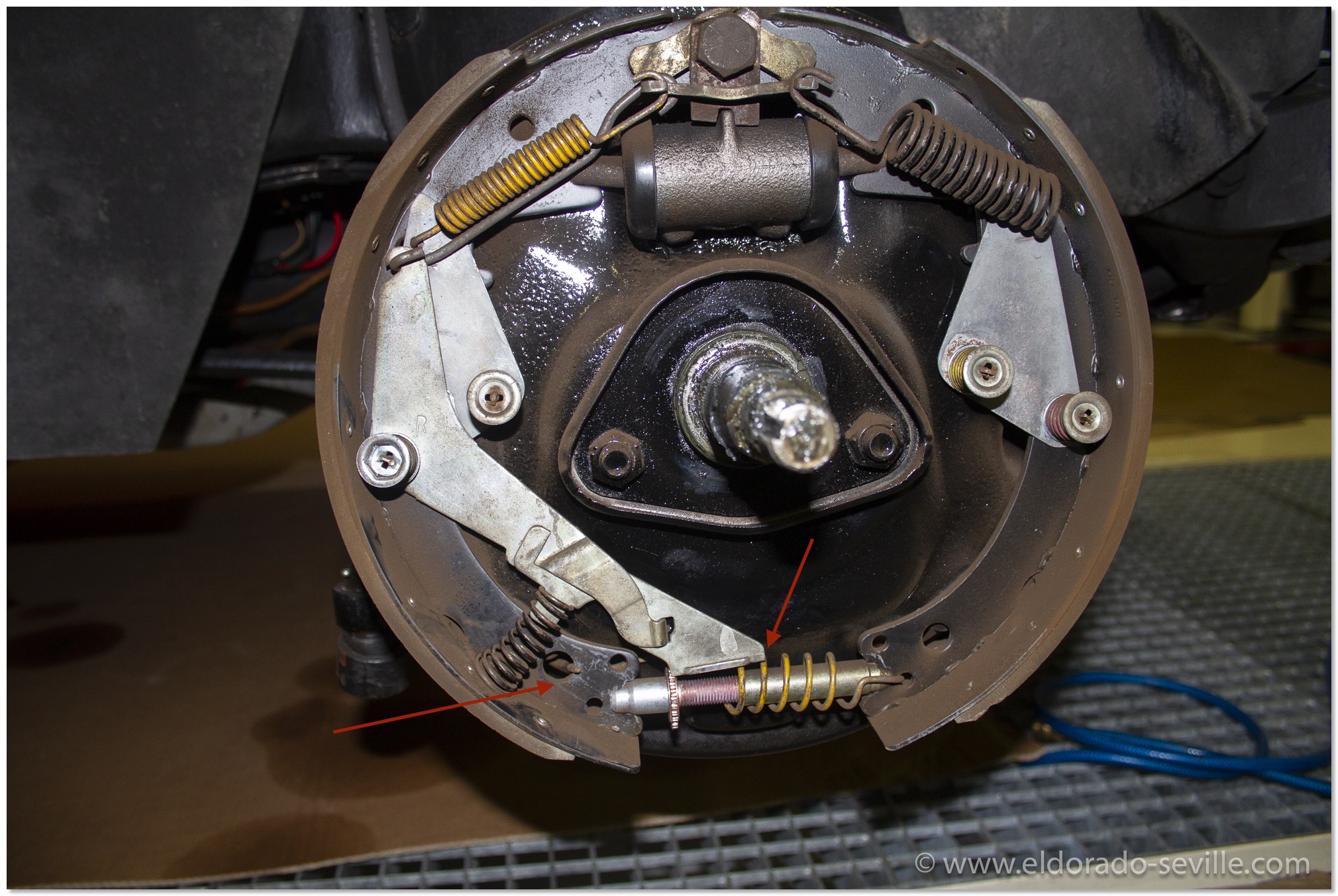

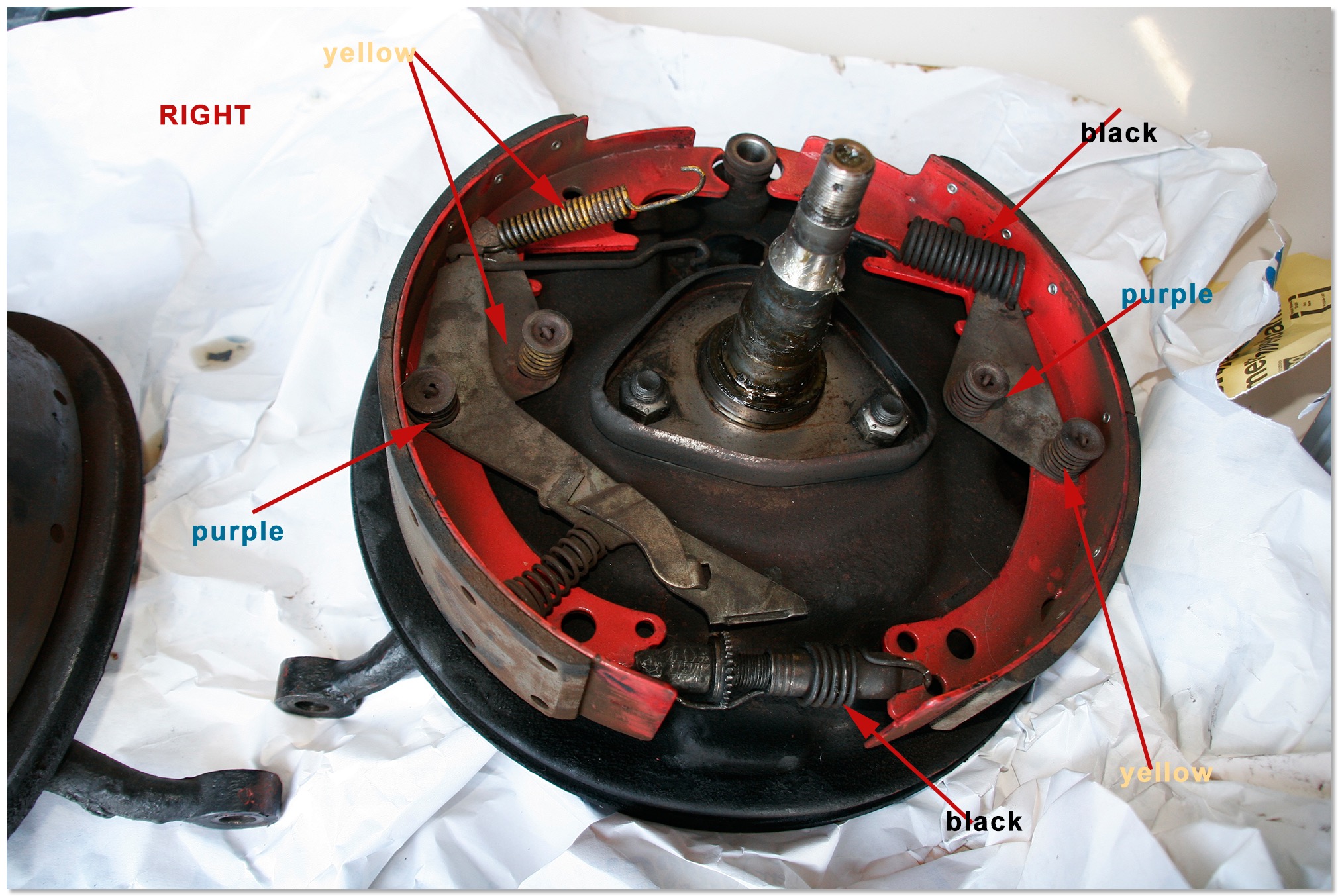

This is how the last shop which worked on my brakes assembled my right front brake… I will never let a "professional" touch my car again… They used the wrong spring and non fitting front adjusters. To make things worse they attached the wrong spring to the wrong holes in the brake shoes which stretched the spring and made it unusable.

This is how the last shop which worked on my brakes assembled my right front brake… I will never let a "professional" touch my car again… They used the wrong spring and non fitting front adjusters. To make things worse they attached the wrong spring to the wrong holes in the brake shoes which stretched the spring and made it unusable.

This is one of the many detailed pictures I provided to the shop to make sure they would reassemble the brakes correctly… They failed miserably!

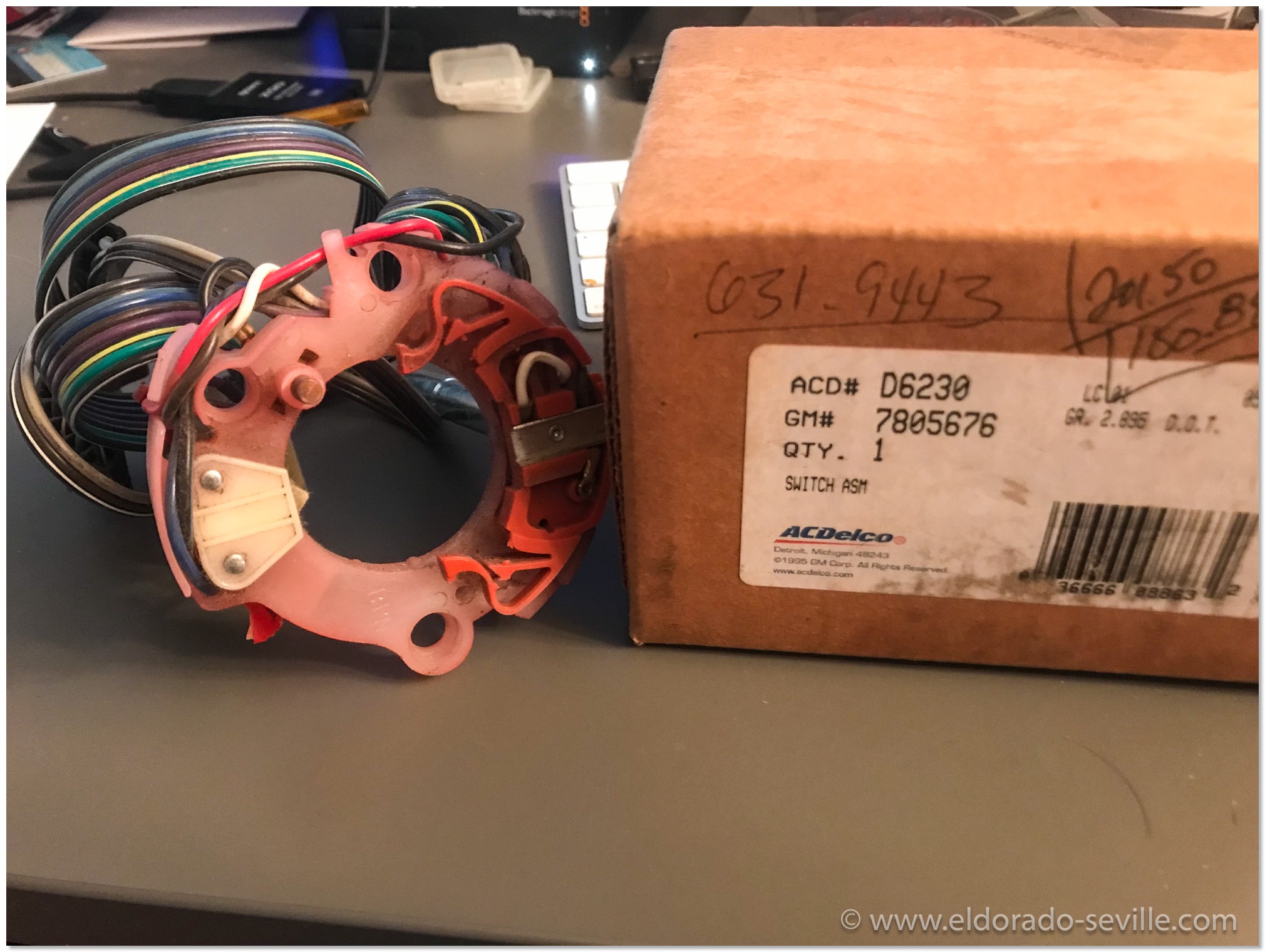

I FOUND A NOS 1967 CADILLAC T&T COLUMN TURN SIGNAL SWITCH.

This switch is almost impossible to find GM #7805676 ACD# D6230. It is for 1967&68 Cadillacs with Tilt and Telescope column.

READ MORE...A6 AC COMPRESSOR REPAIR - BAD BEARING ON THE 1974

Due to all the other projects I never managed to get the AC back in fully working order until now.

Unfortunately the rebuilt AC compressor came with the clutch coil terminals in the wrong position. They are available with the terminals at the correct 10 o clock position or the 2 o clock position, which is correct for other years.

If the terminals are in the wrong position you cant connect the original wires to them as they are too short. With the high shipping costs it was no option to send the incorrect compressor back.

As it turned out the cars original compressor had a bad bearing and that was the reason why it was disconnected.

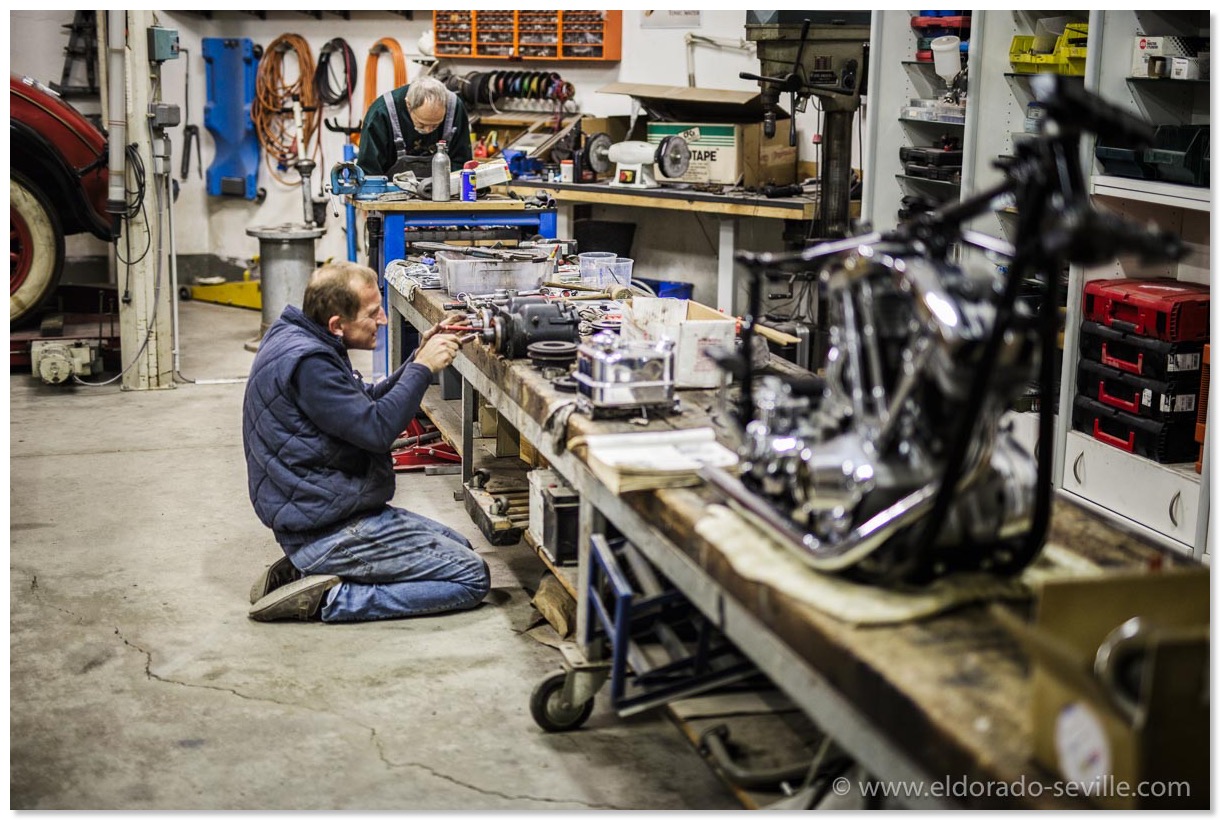

My friends Lucky and Steve were here to help me with the compressor project and so I took both of my compressors to Lucky´s workshop, as he has all the necessary tools and experience with these compressors from his own cars.

Originally I just wanted to turn the clutch coil on the rebuilt compressor into the correct position, but then we decided to rebuild the original compressor instead, because it still has the original decal, which is not available as a correct reproduction. All the available compressor reproduction decals are TOTALLY incorrect for the 1974 Cadillacs. The 1974 reproduction decals all show the wrong amount of refrigerant! They are also different in many other details. The closest match of reproductions for 1974 are the ones from 1972 Cadillacs…

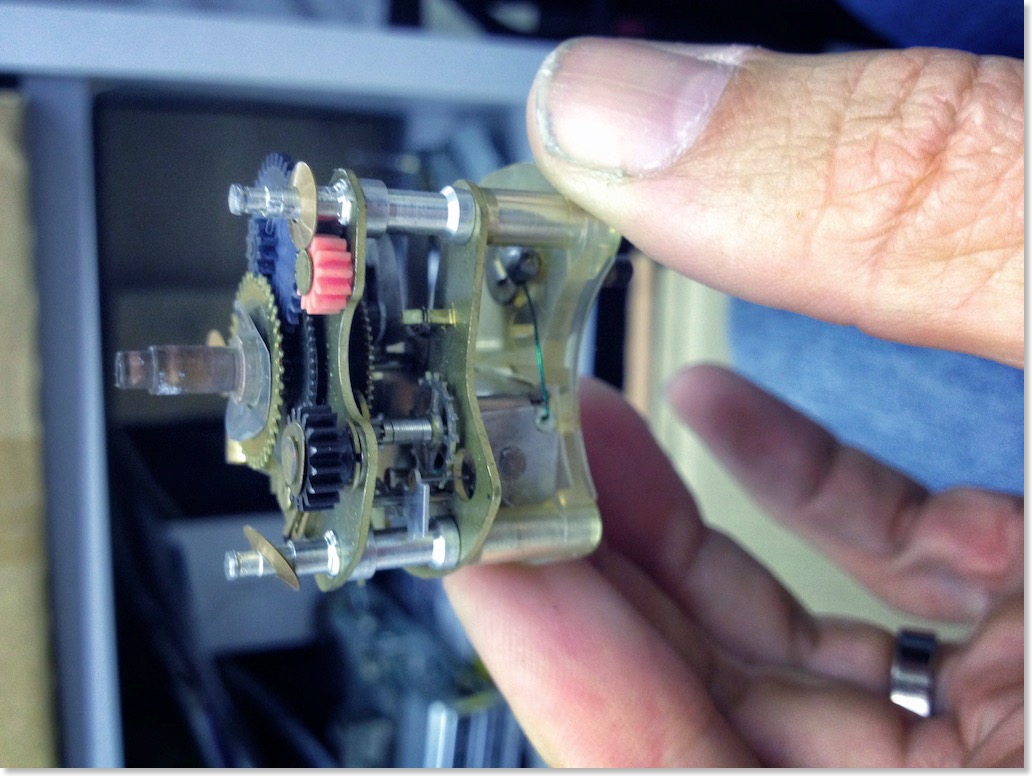

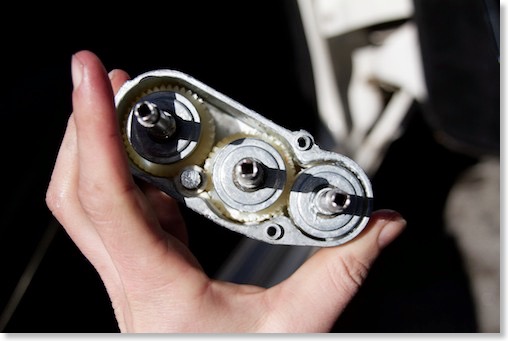

We still disassembled the rebuilt compressor to "borrow" its pulley bearing to replace the bad one on the original compressor.

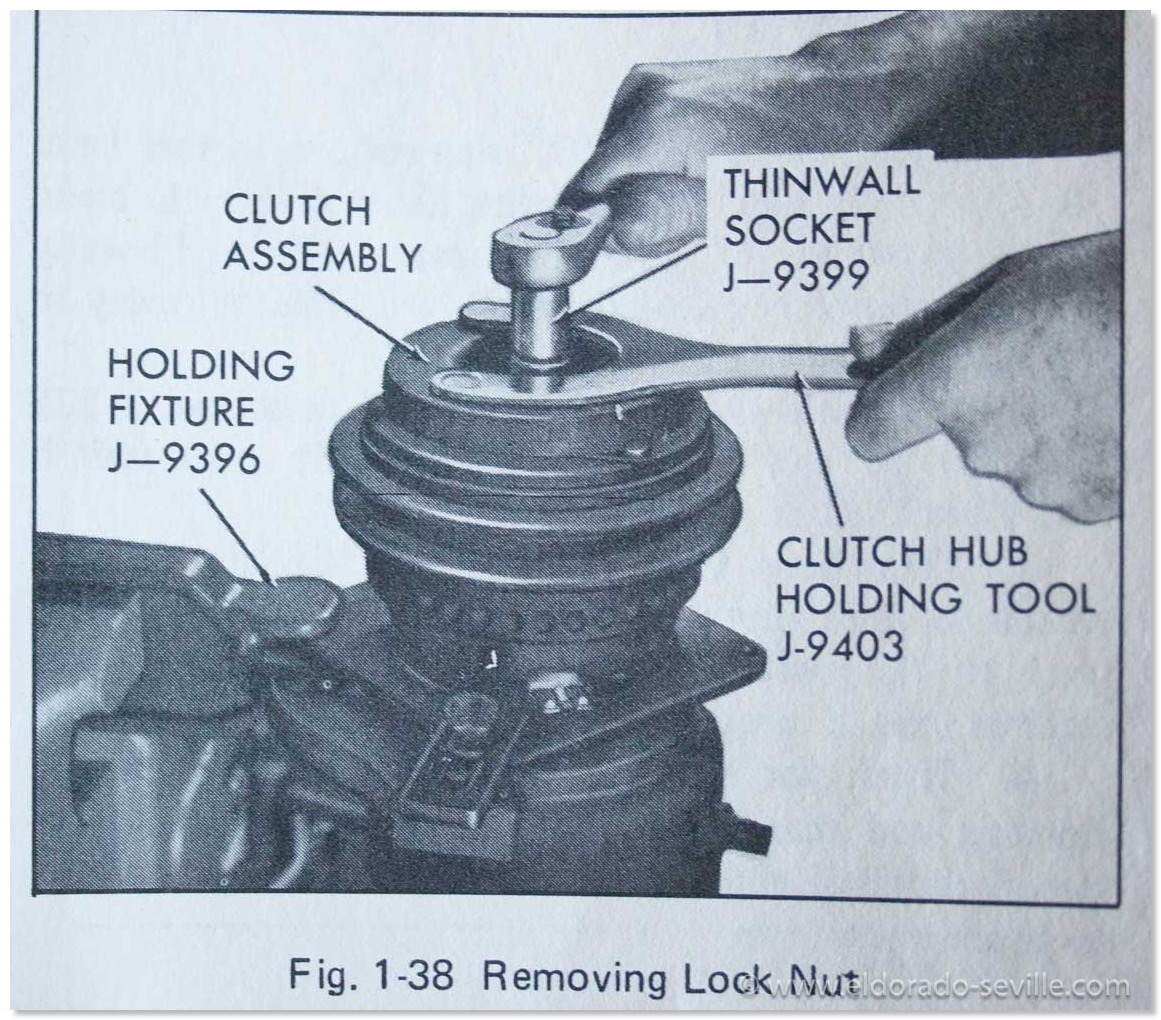

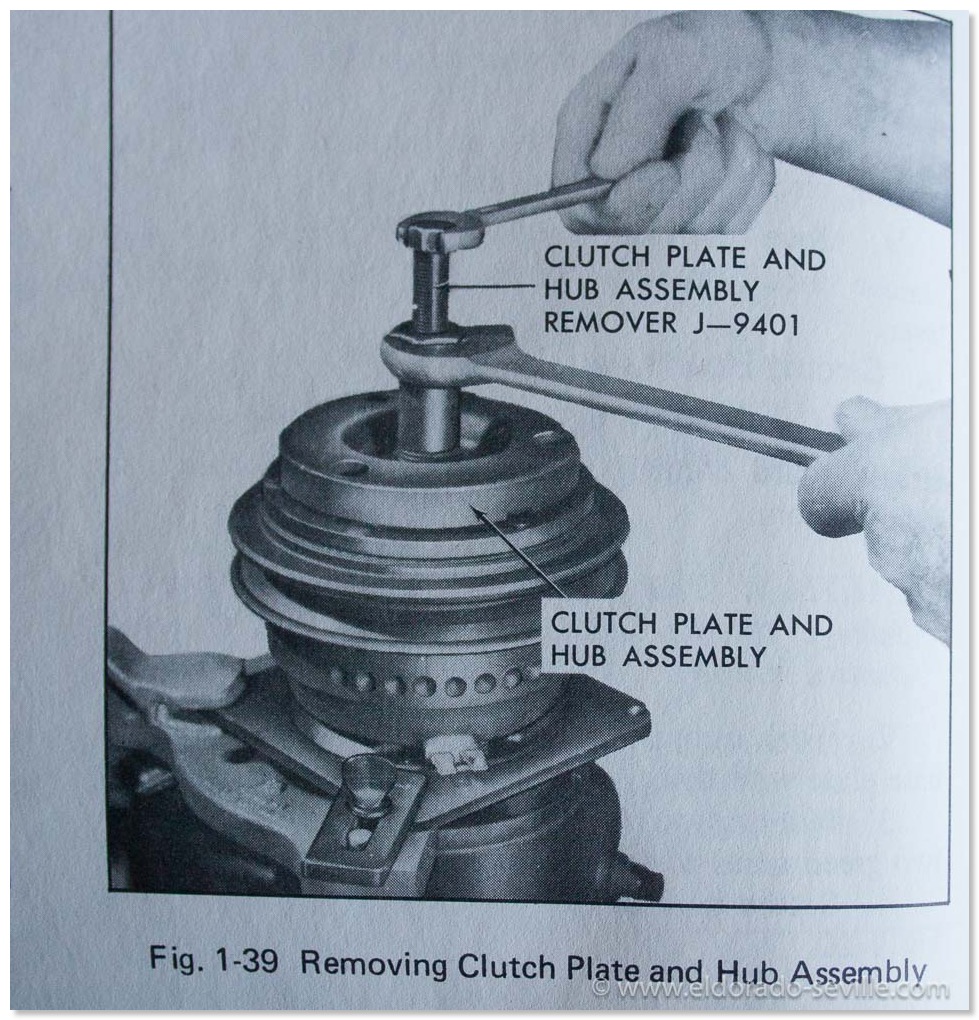

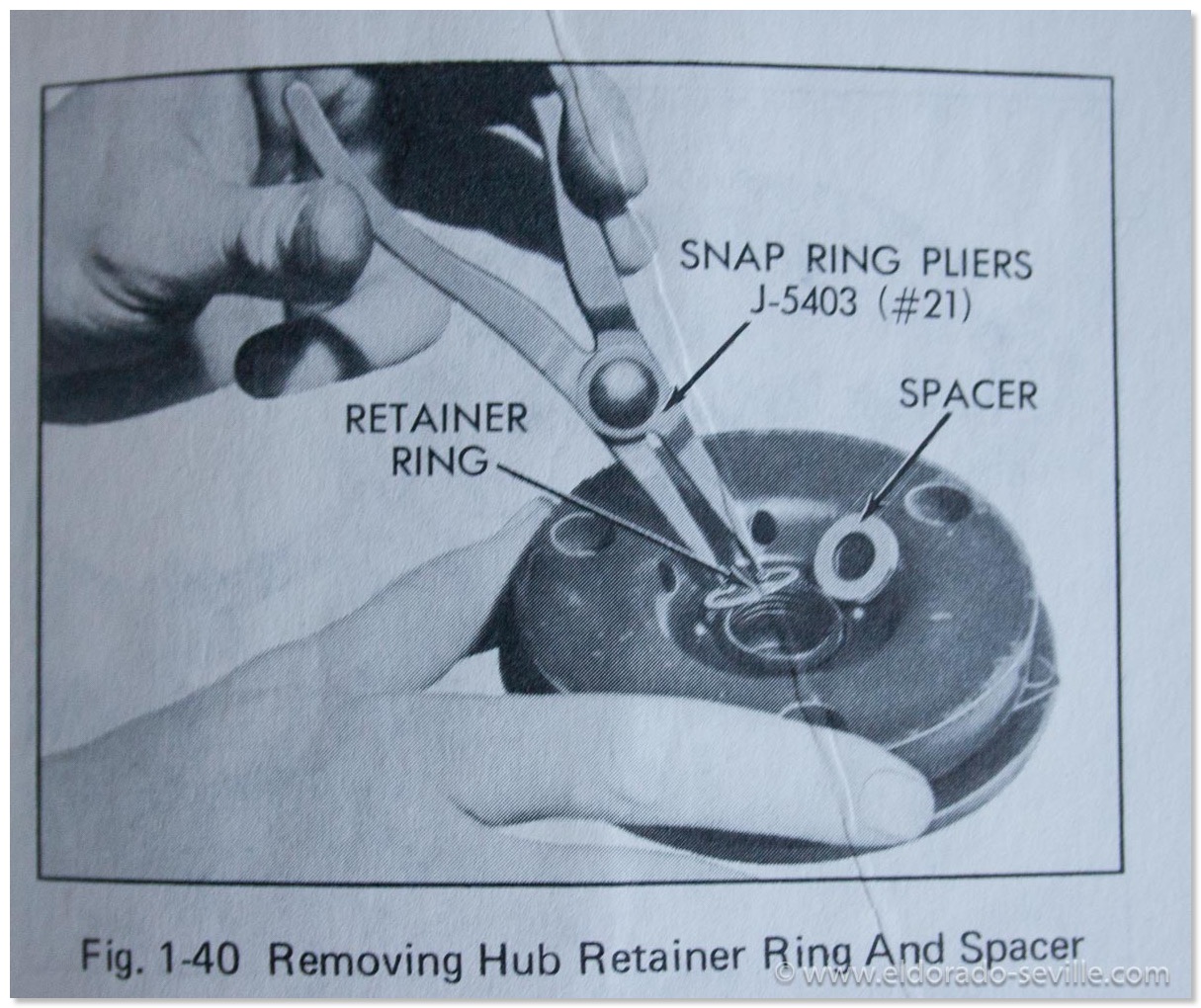

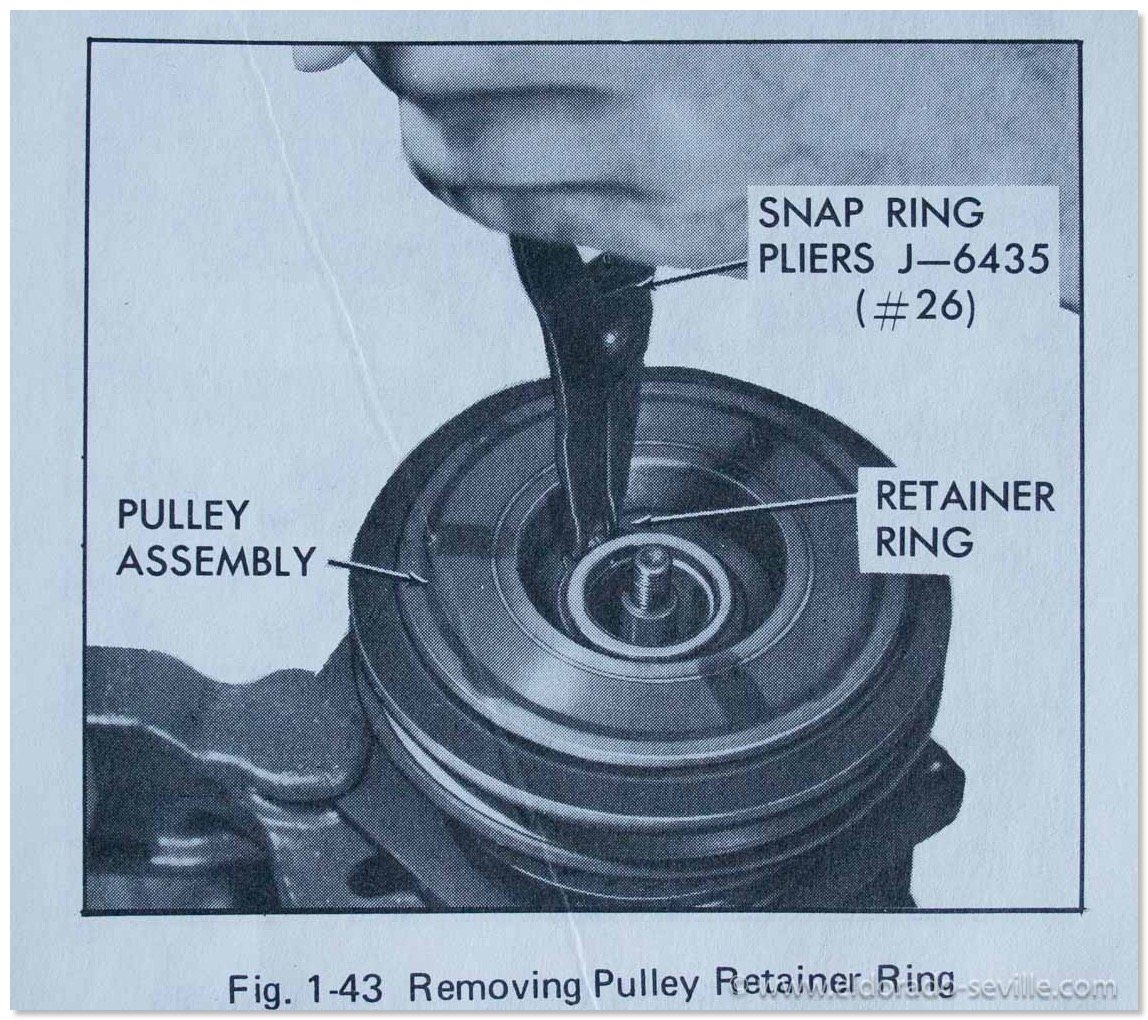

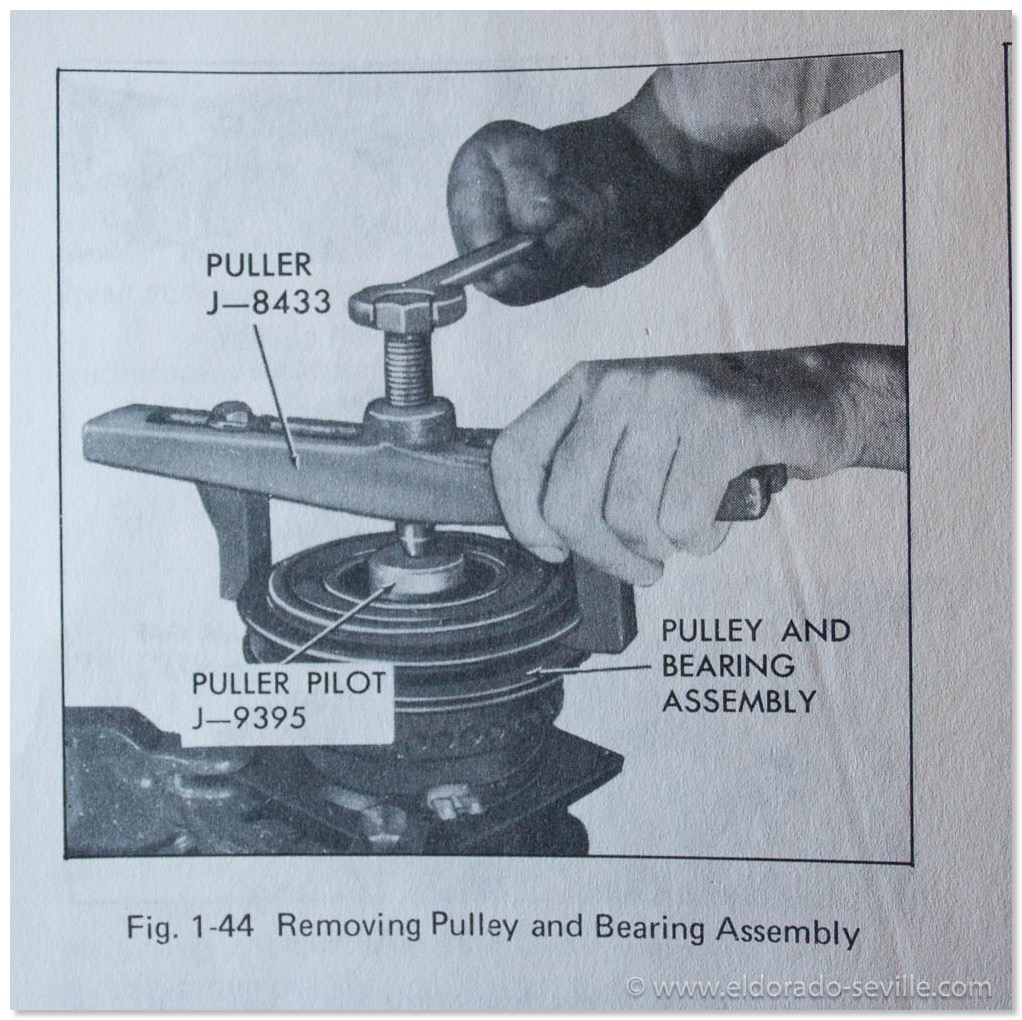

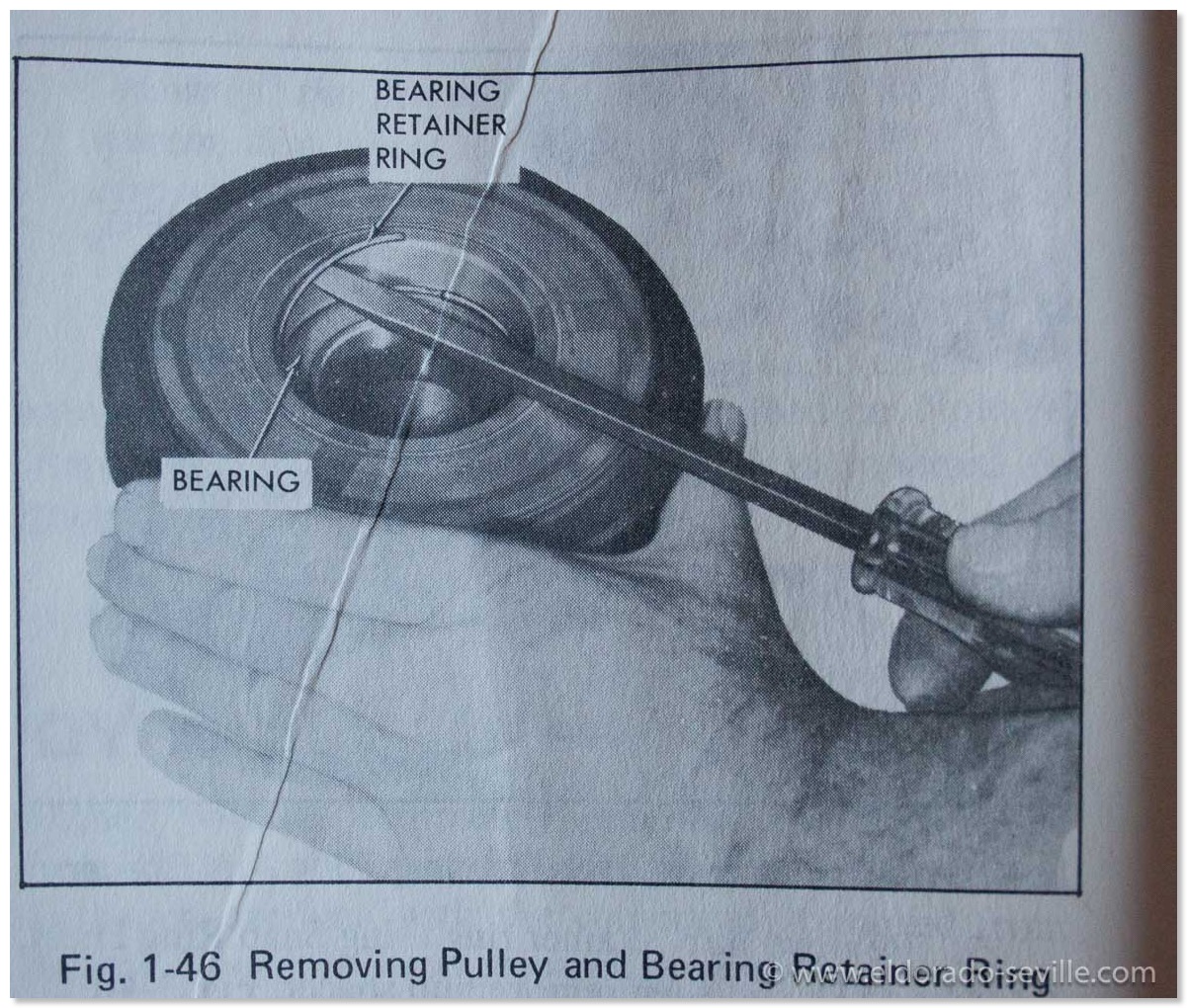

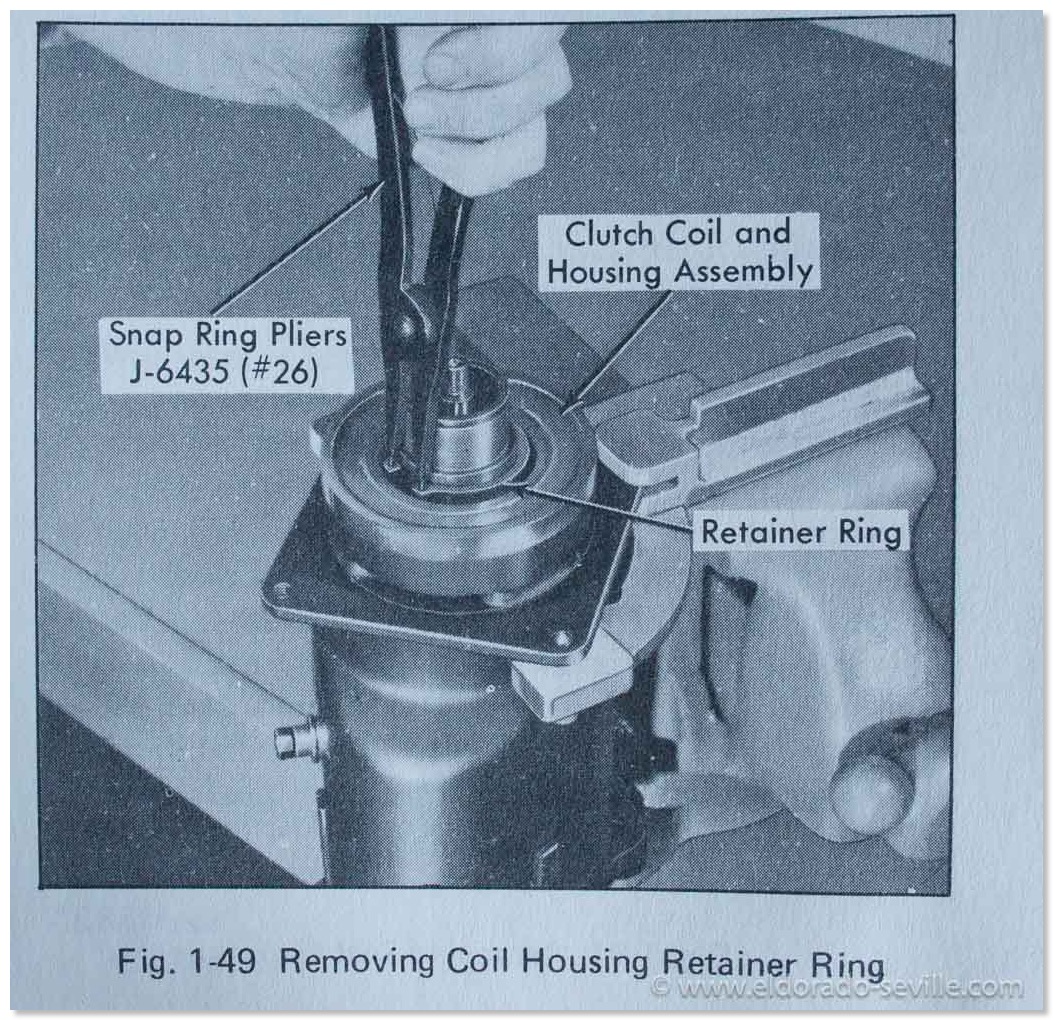

The procedure to be able to replace the bearing and to turn the clutch coil is not too difficult - but you need some special tools. Without those you cant do it. You´ll need a basic clutch puller / installer set for this job and some long nose snap ring pliers to get the retaining rings out.

First remove the shaft nut and the snap ring ( the rebuilt compressors always seem to come without this snap ring) and then pull the clutch with the special puller. Pull off the pulley and take the bearing out and replace it with a new one.

To be able to turn the clutch coil you´ll have to remove another snap ring. This snap ring was the biggest challenge for us. The shop manual lists a special tool for this which we of course did not have… It could be done with a very long nose plier as well, but we did not have these either. So it took us quite a long time to get it out with screwdrivers and self made hooks… You can then simply turn the coil into the correct position.

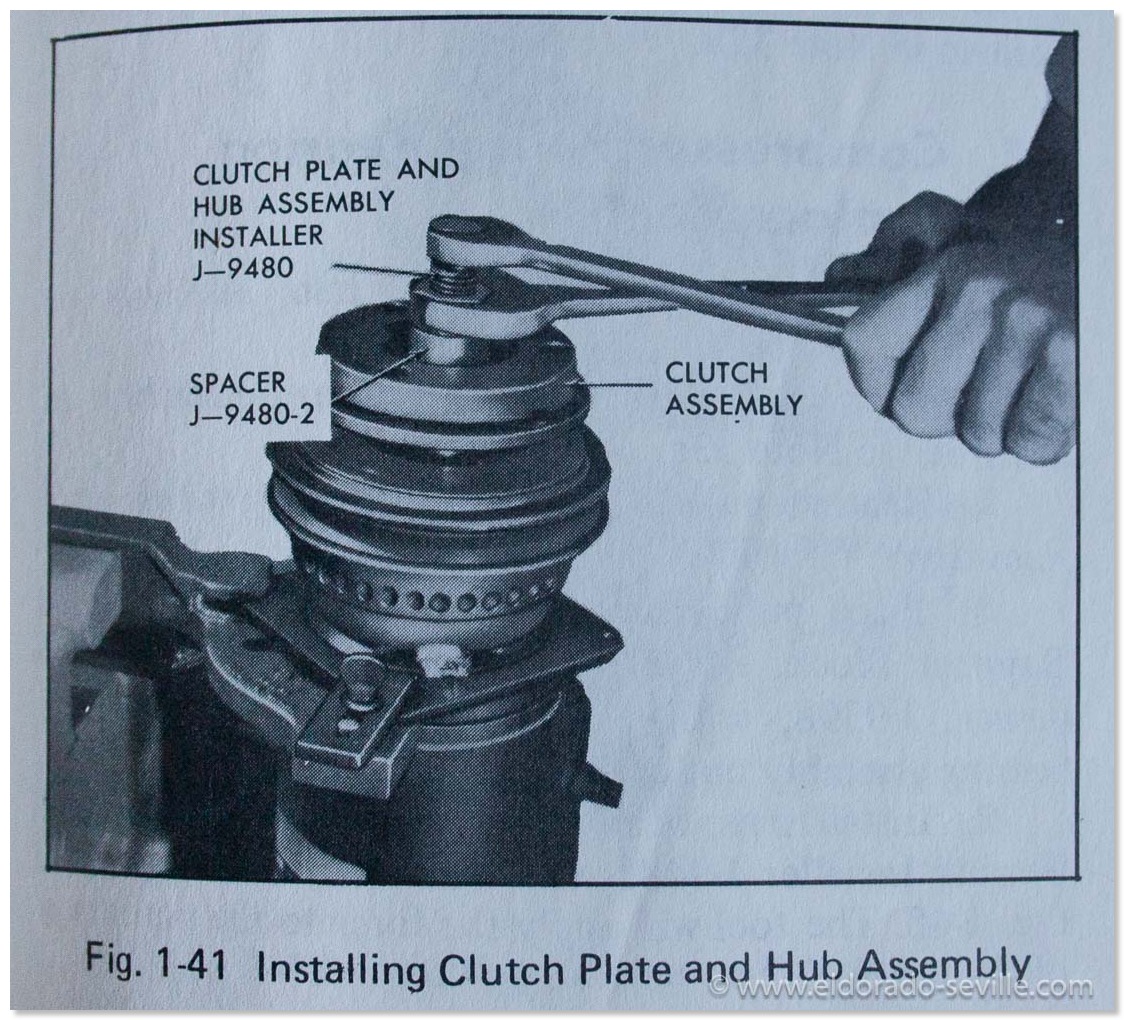

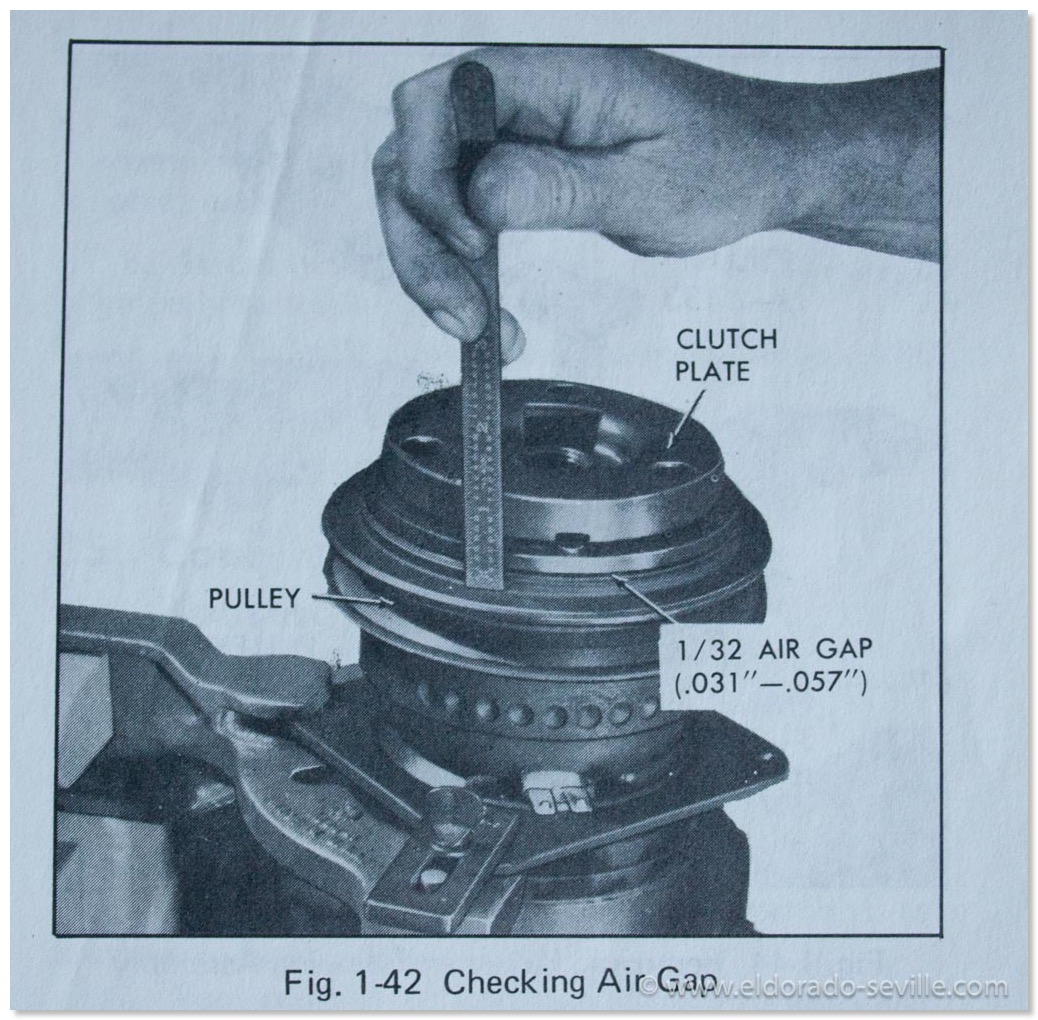

Putting it back together is pretty straightforward as well, but again you need a special installer tool to get the clutch back on and to adjust it properly.

I will now have to buy a new bearing so that I can put the rebuilt compressor back together and have it as a spare.

I have attached some pics from the shop manual which show how to remove the various parts of the compressor to remove the pulley and the clutch coil.

As always you can find ALL the pictures in my restoration gallery!

You need some special tools to disassemble the A6 AC compressor.

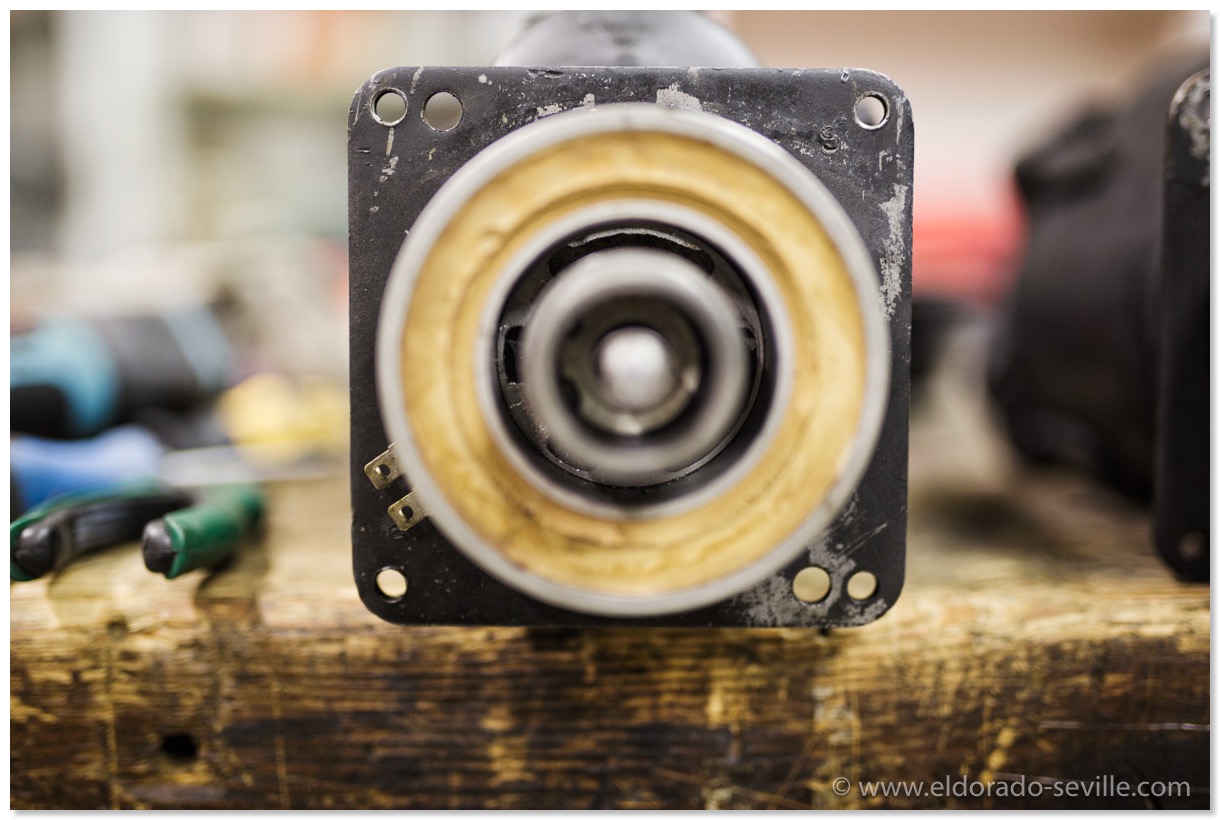

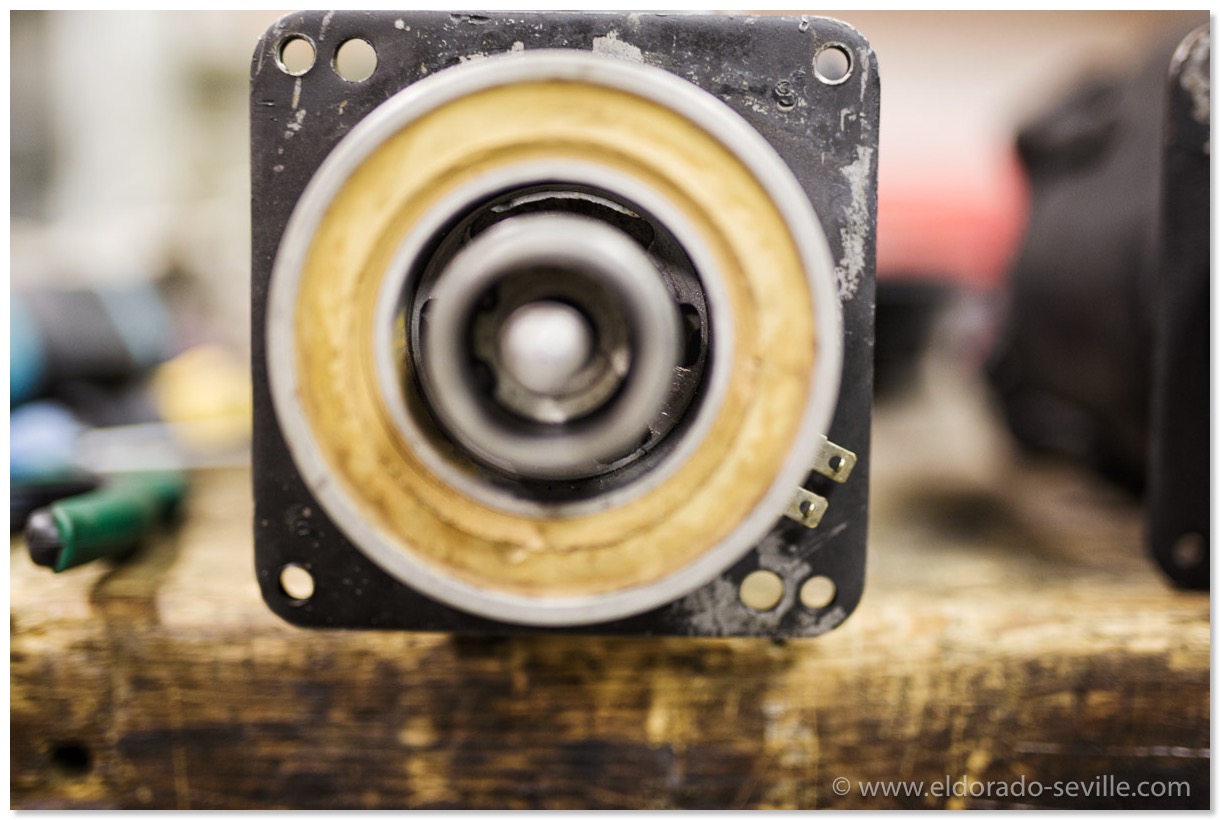

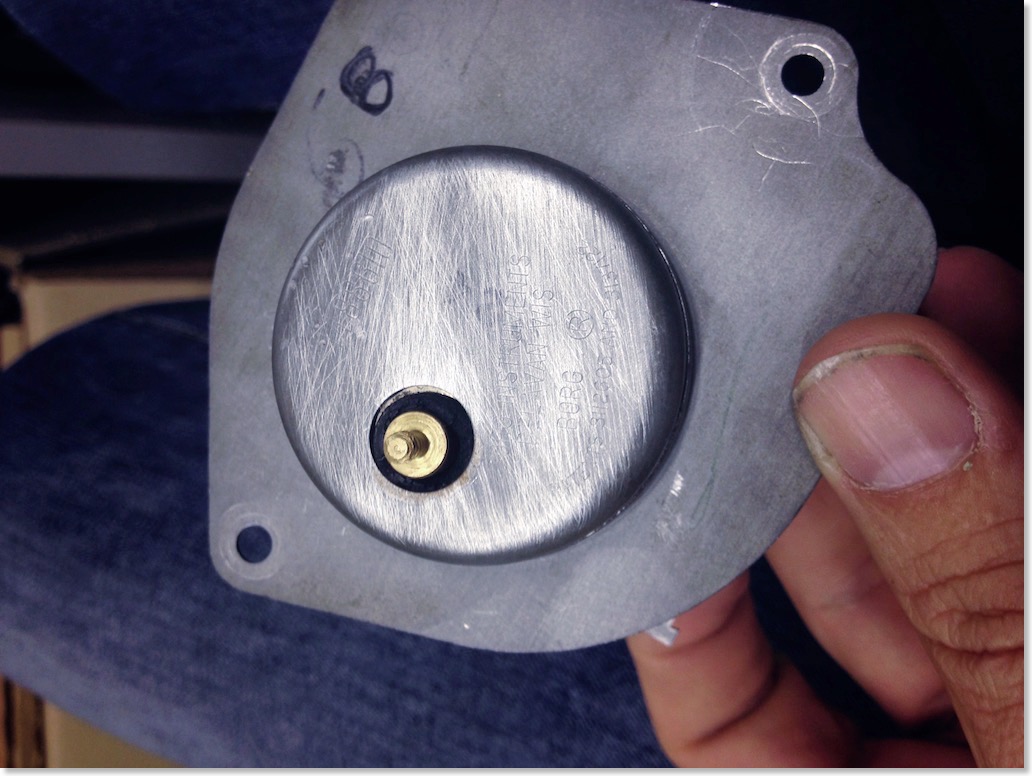

On the 74´s original AC compressor clutch the bearing was bad.

The compressor clutch removed. You can see the bad bearing inside which is normally sealed. Some balls were already missing.

The clutch with some remains of the bearings.

The clutch and pulley removed on the original compressor.

My friends Steve and Lucky at work. We also replaced all the O - rings.

Removing the pulley

Removing the pulley from the rebuilt compressor.

There is this one snap ring we just did not have the right tool for. The shop manual lists a special plier for this. After a lot of fiddling we got it out eventually…

The magnetic coils on the rebuilt and the original compressor

Lucky in action

Once the snap ring is out you can turn the coils terminals to the 11o´clock position or the 1 o clock position. On the 74 it has to be at the 10 o clock position, otherwise the connecting wires are too short.

Getting this snap ring out was the hardest part on this job, due to not having the right tool for it.

The terminal at the incorrect position at the rebuilt compressor.

We turned the terminal to the correct position.

We sandblasted the pulley while it was out of the car so that I can repaint it now. Note the original decal! All the available reproduction decals are totally incorrect for the 1974 Cadillacs. The reproduction decals all show the wrong amount of refrigerant! They are also different in many other details. The closest match of reproduction decals for 1974 are the ones from 1972 Cadillacs…

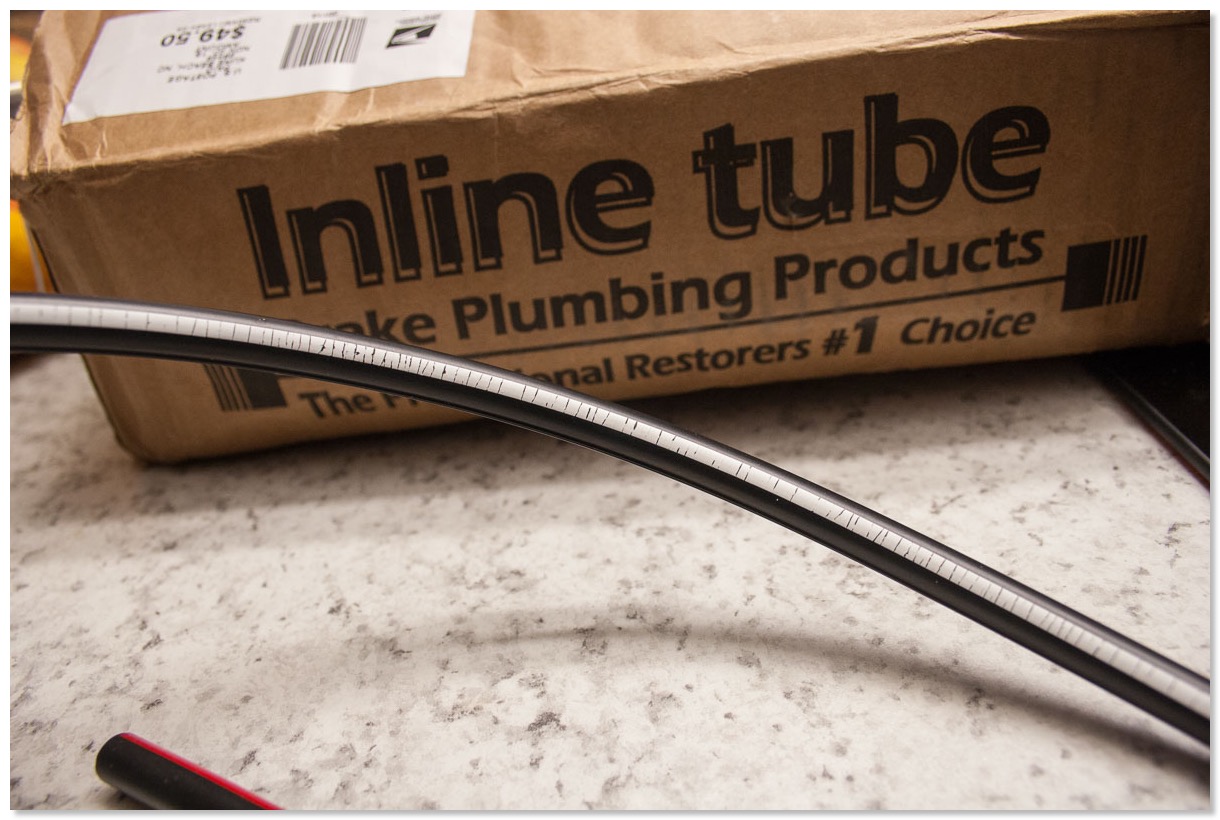

COLOR CODED VACUUM HOSES - BEWARE OF TERRIBLE REPRODUCTIONS!

These vacuum hoses unfortunately get extremely hard and brittle over the decades under the harsh conditions in the engine bay. Often they literally break into pieces by just touching them.

On my 67 Eldorado I had to replace most of the vacuum lines when I got it - and it really has a lot of hoses.

When I searched for reproductions I could not find a really good source and I gave up.

At my ongoing project on my 74 another of these original lines fell apart while working in the engine bay. So I started to look for the correct hoses once again.

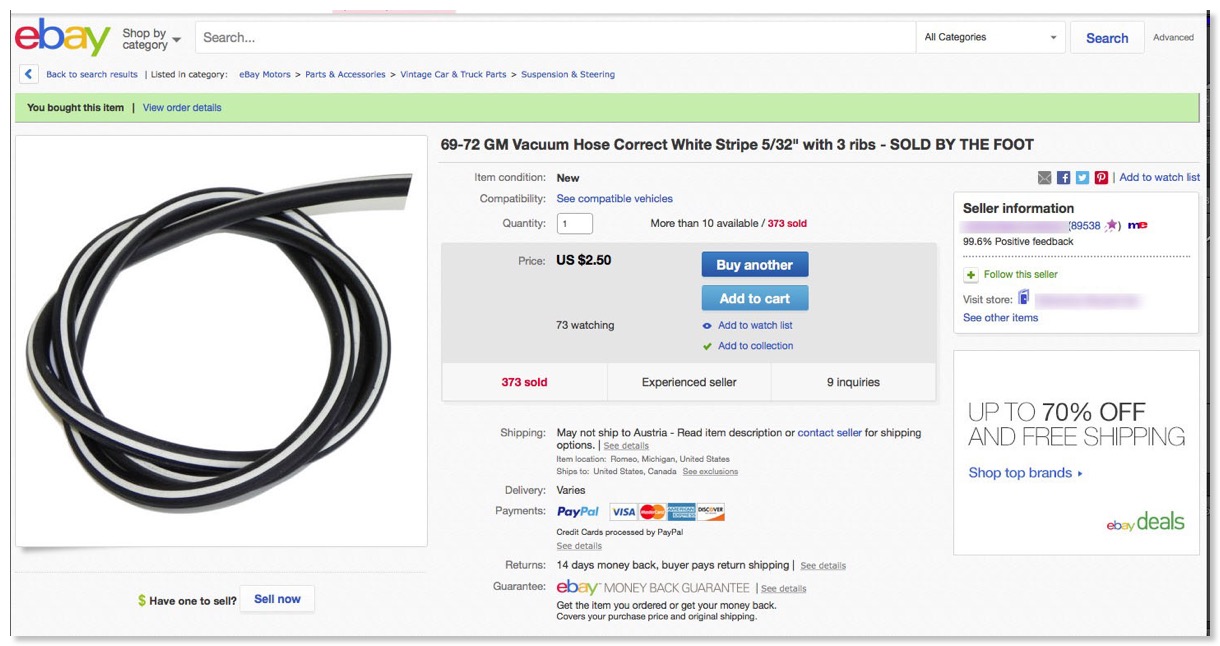

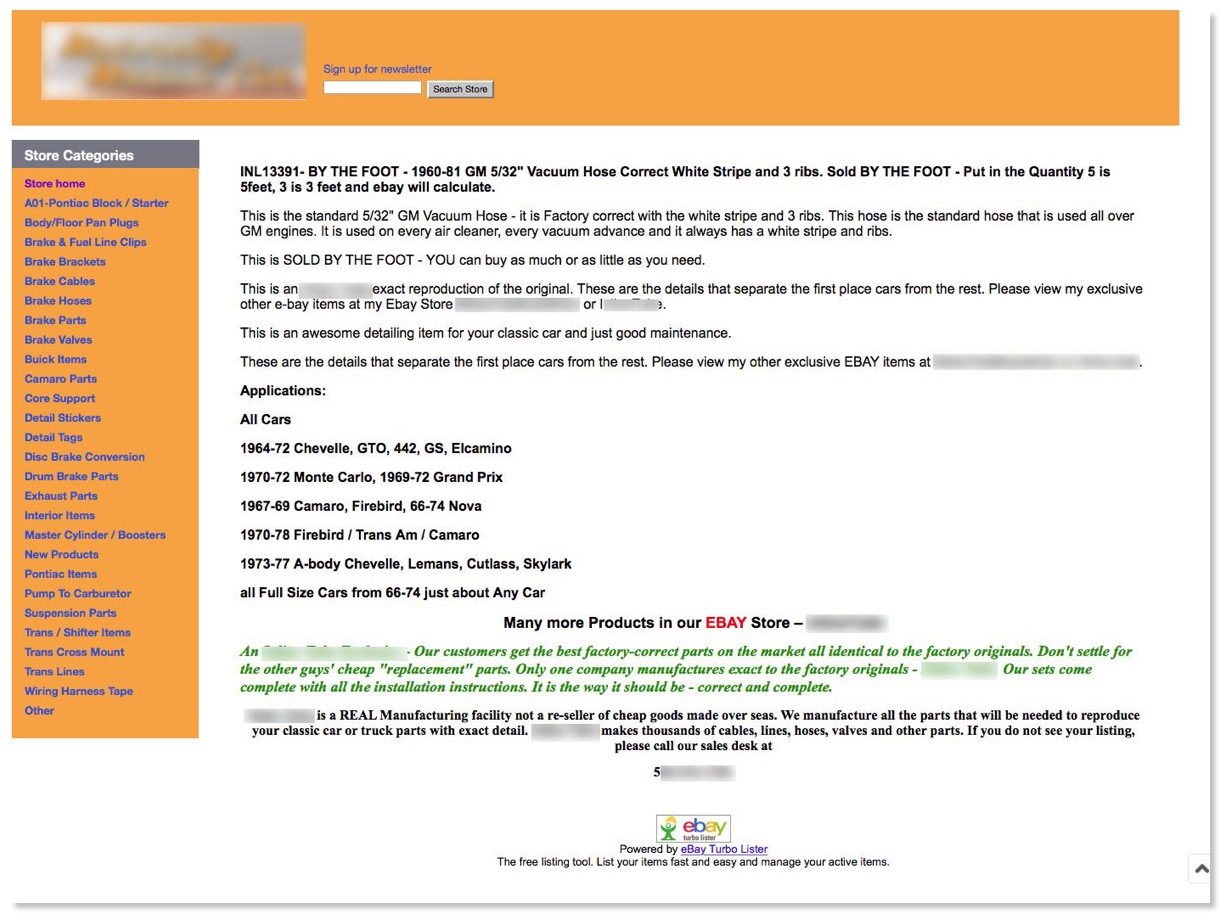

Soon I found a link on ebay to a well known seller, whose name I do not want to mention, offering the lines in all the colors I needed.

I ordered quite a few Ft of each color.

The seller describes them as factory correct and as a perfect part - see screenshots below.

As they do not ship to Europe, a friend of mine was so kind to forward the hoses to me.

When they arrived I was shocked - I have never ever seen a worse product.

The paint is peeling off or missing at all. As soon as you even slightly bend the hoses, the paint on the stripes just cracks and falls off. It could not be worse.

Also the hoses are too thick and the walls are to thick. The original hoses are quite a bit slimmer than these crappy reproduction hoses.

They also charged me for 15ft of red striped hoses but only sent 10ft. This was about the worst buying experience ever.

I´m trying to return the hoses at the moment - but communication with this seller is terrible.

I normally never criticize sellers here on my website and never leave any negative comments on ebay - but this is the worst I have ever experienced.

Shipping back these hoses will cost me at least $50 and I already paid $60 for having them shipped to me in Europe - with the import tax I will have lost $160.- for this BS… Money I would urgently need for some other parts… :-(

I´m now trying to find another good source for quality reproduction hoses. There is one Corvette parts dealer which looks promising as he offers some great kits for Corvettes, but they are all pre-cut… I hope he can send me some ft. of the hoses I will need - I hope that I will get a positive reply.

Ebay seller screenshot - this is how they describe the hoses…

As you can see the paint stripe is just cracking everywhere.

As you can see the paint stripe is just cracking everywhere.

As you can see the paint stripe is just cracking everywhere.

As you can see the paint stripe is just cracking everywhere.

As you can see the paint stripe was not even painted correctly on the green hose…

FIXING A LEAKING VALVE COVER ON MY 1967 DEVILLE

The gasket was replaced a couple of times since I own the car, but it never was very successful in stoping the leakage.

After my last attempt it leaked even more than before…

The valve cover design of the 429 engine is not exactly the best from a technical standpoint. It's only held in place by 4 screws.

I did some research and tried a different approach this time to seal it.

First I used a different valve cover from a spare engine I have in my garage which did not show any signs of leakage.

I had to fully detail it first to make it look perfect. I repainted it with Bill Hirsch Engine enamel in the correct color.

I made sure that everything was flat as these cover often get warped at the bolt holes by over tightening them.

They checked out flat. I then glued the new cork gasket (I used a Fel-Pro gasket) to the valve cover with high temp gasket sealer. To make sure that it stayed where it belongs to I used a lot of cloth pins to keep the gasket in place.

I let it dry over night.

The next day I put some wheel bearing grease to the other side of the gasket and put it back on the heads. The grease helps to make sure that you can remove the gasket any time again.

I then tightened the four bolts to 28 INCH/Pounds of torque as specified by the shop manual. (thats 3,1 NM) I had to buy a small torque wrench for such a small torque rating first… I could have never guessed how much torque it is.

I then ran the engine and let it cool down and re-torqued the bolts afterwards.

After the first 25 miles test drive it seems that the valve cover is 100% leak free for the first time since I own this car.

I´m not sure what fixed it this time, but during my research I read multiple times, that for cork gaskets one should not use gasket sealer on the head side of the gasket, and one should only use grease instead. Some recommend that gasket adhesive (spray) should be used to keep the gasket in place in the valve cover.

I know it looks very strange, but I used cloth pins to make sure that the gasket is glued to the valve cover properly…

THE 1967 WATERPUMP PROJECT IS COMING TO AN END - DETAILING THE AC COMPRESSOR AND A LEAKING VALVE COVER

The project had a major delay as the reproduction radiator hoses were held by customs for 5 weeks. Its unbelievable…

I could now finally refill the cooling system and start the car again with the new water pump in place.

The car fired right up although I had also removed the distributor and forgot to mark how it was in. So I had to find TDC (top dead center) before I could install the distributor back into the car.

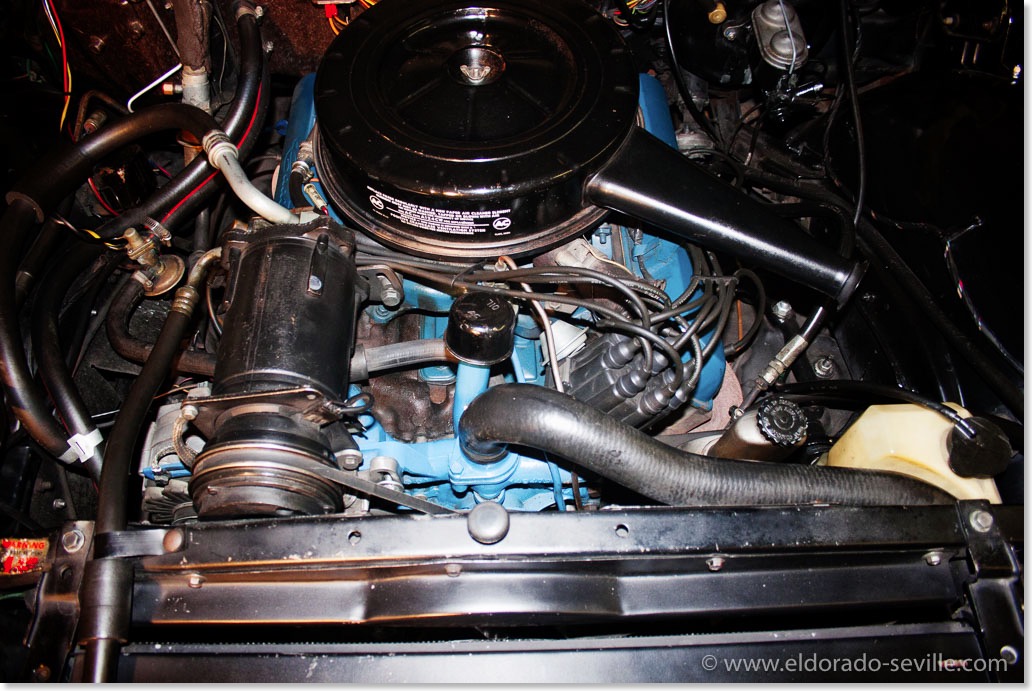

I also bought a cheap timing light and set the timing to 5 degrees. You have to set idling to 480 rpm, disconnect the vacuum hose to the distributor and the parking brake and plug the hoses to set timing correctly

After the first few miles I am quite satisfied with my work. I hope that everything will stay like this and that no leaks will show up.

Only the right valve cover where I had replaced the gasket seemed to have a slight leak with oil dropping on the exhaust manifold... Looks like I will have to take the compressor out again to be able to take the valve cover off again and install another new gasket… But first I will have to find out why it is actually leaking. I hope that the cover itself is not warped as it was already leaking before on exactly the same spot. Often these covers get tightened down too much. All it needs is 28 INCH pounds of torque (3,1 NM) I will also make sure the screw holes have not become dished (usually due to over-tightening of the screws). Use a small block of wood as an anvil and a small hammer to flatten the screw holes back out.

The engine somehow runs and idles better than before and has more power. It seems like the ignition was off before. I had the car tuned by a professional years ago - another thing they did not get right...

The new reproduction hoses I got from Fusik are also in place with the correct tower hose clamps. The hoses have the correct numbers stamped on, but compared to my original hoses the stamping looks different where the numbers are much smaller. The hoses fit very well, only the lower radiator hose had to be cut a little to fit.

I also detailed the replacement AC compressor I installed years ago. I bought a new reproduction decal which is a very good match to the original decal. In general I found out that all the reproduction decals available out there are not a 100% match. They look very similar but they all differ in size, spacing of the numbers, and most of the time the font used is very similar, but not exactly the same. I have no idea why the manufactures did not get it 100% right. Maybe I will have to produce my own decals in the future… Most of the AC compressor labels you can buy are incorrect for the year or model they are offered. If you want to get the correct one for the 67 Deville you will have to buy the one for the 67 Eldorado. Often these reproduction decals have the wrong colors, numbers and R12 capacity on them. So do your research to get the correct one.

Another challenge was to reproduce the O.K. inspection stamp. Years ago I found the stamp on ebay and experimented with different kinds of paint and never got any useable results.

Eventually I found a stamp kit set for Corvettes which included the correct yellow paint and a stamp felt and the Corvette stamp. I could not use the Corvette stamp of course, but the rest of the kit is perfect and finally I could apply the stamp to my AC compressor which now looks factory new again.

The engine is back together

The detailed AC compressor

The O.K: final test stamp

A NEW WATER PUMP FOR THE 67 DEVILLE AND DETAILING THE ENGINE

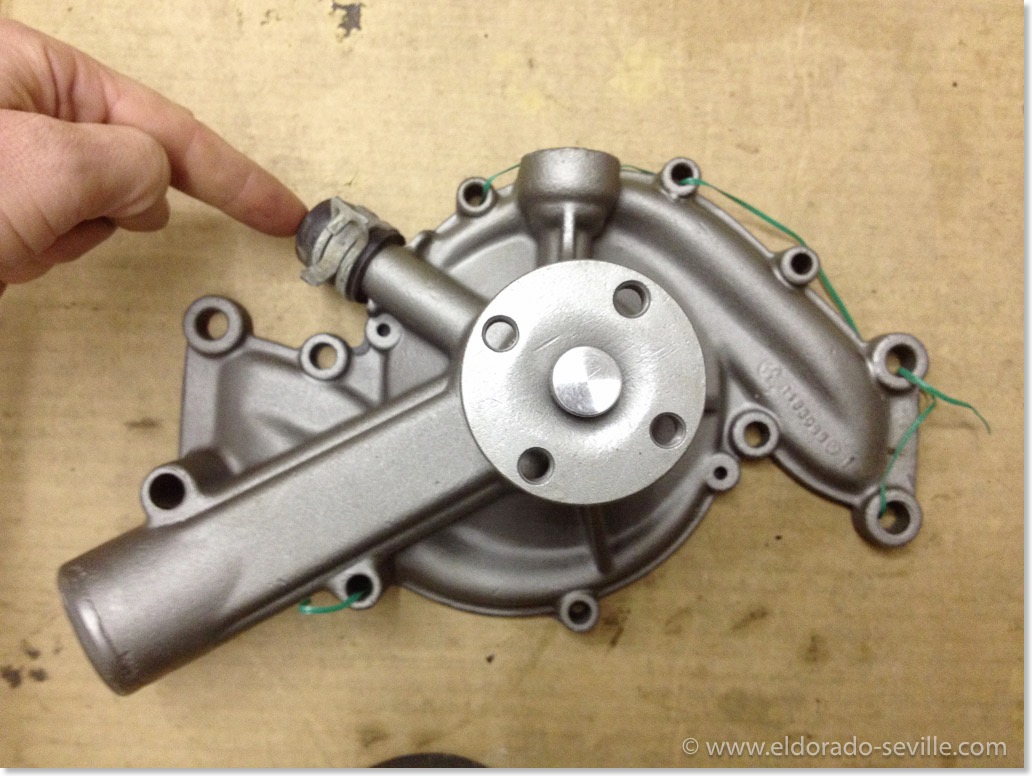

So I ordered a new, high quality rebuilt water pump from one of my favorite sources. When I got it, I found out that it was one for a 64/65 Cadillac with an additional water outlet. This seems to be the type everybody is selling nowadays and it is much more common. It will fit the 1967 429 engine and it even has the additional water outlet pre-plugged with a rubber plug. The problem I had with it, is that it looks completely incorrect on the 1967 Cadillac, and so it was not acceptable for me.

I then found a very good source for Cadillac parts. They are priced higher than other outlets (if you can even find this parts anywhere else..), but David - the owner - offers only 100% correct and high quality parts. He also has a huge collection of NOS parts. I found some parts through him that I did not find anywhere else. His customer service is excellent as well - I can highly recommend him.

Until around 2009 I had most work on my cars performed by a restoration shop specialized in American Cars. Then I decided to no longer go there for a lot of reasons. With the growing numbers of cars I collected, I could no longer afford to pay somebody to have all the work done, and I no longer accepted to pay good money for lousy work and bear the shop owners terrible attitude against his clients.

Now that I´m trying to do everything by myself, I found a lot of bad work the professionals did, and sometimes I´m really shocked to see what I wasted my money for, but I had no idea about cars and they could have told me everything and I would have believed them…. Lots of work they did leaves a lot to be desired, and you can see some examples in the pictures below…

When they repainted parts of my 67 Deville´s engine, they used the completely incorrect Cadillac blue, which was used from 1977 on. I always hated it, and now that I had to disassemble so much to replace the water pump they did in 2001, I decided to paint everything correctly.

I detailed all the parts I took off and had them media blasted. After they were cleaned, I painted them with the correct shade of Cadillac Blue. Bill Hirsch engine enamel is the best and most correct engine enamel for Cadillacs. You can see lots of pictures below which document what I did. Besides the incorrect paint I found out that fuel lines were damaged, bolts were missing or broken off and many other small flaws which I corrected now.

I´m now waiting for the correct upper and lower radiator hoses to arrive, which are reproduced by Fusick, to replace the still original hoses from 1967! The originals still look great and would probably last for a long time, but I do not want to take any chances… I am now hoping that nothing is leaking and that I wont have to re-do any of the work.

When I took the radiator out, the overflow tube came loose. I already had the same problem years ago, and it was not fixed properly by the restoration shop… Luckily I found an old gentleman locally, who could brace it back together the old school way. I will of course detail the radiator as well before installing it back into the car.

This is a short video which shows the problem I had with the water pump and the bad bearing. You can clearly see the wobbling of the shaft and hear the shot bearing.

This is how the engine bay looked like before, with everything painted in the incorrect later Cadilllac Blue...

The defective water pump is about to come out. I will also replace the painted fuel line with a correct one from a spare engine I have. The water pump made a loud bearing noise and the shaft was a little loose.

I will sandblast and repaint the hot water crossover passage.

Water pump, radiator and valve covers removed.

The water pump was removed - the front cover looks pretty good.

This is the incorrect 1965 water pump everybody is selling for the 429 engines. It will work with the 66 and 67 Cadillacs as well, but it has an additional water outlet which was not used from 1966 on. If you buy them for your 66 or 67 the no longer used outlet is often blocked like you can see on this picture. The correct 1966/67 pumps are much harder to find and way more expensive.

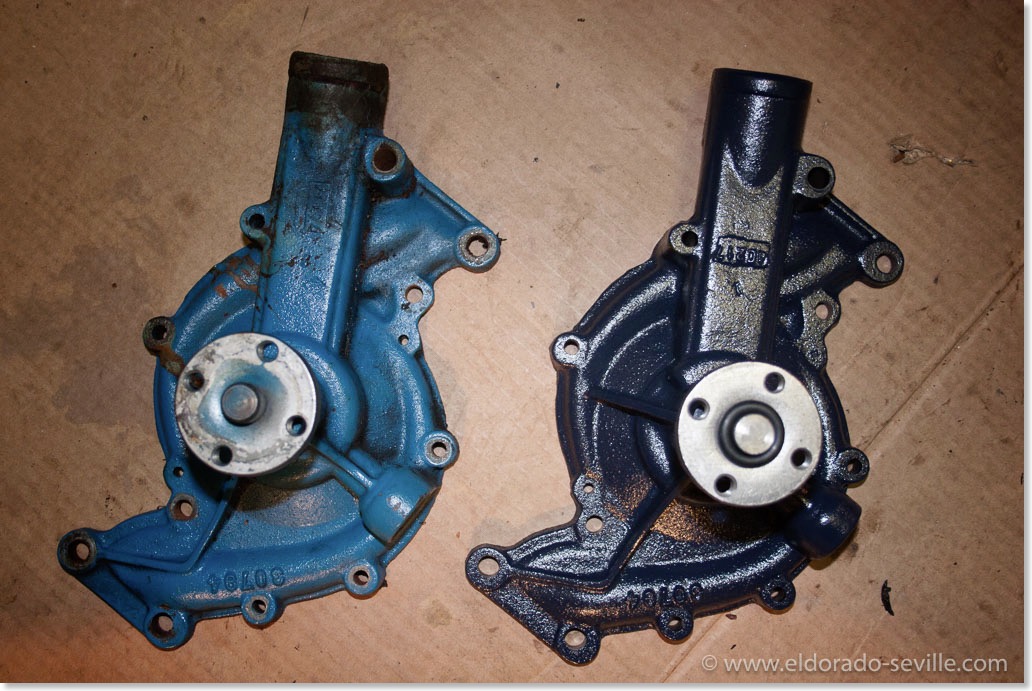

The original water pump on the left and the correct rebuilt 1966/67 Cadillac pump on the right in the correct color.

I will sandblast and repaint all this parts soon.

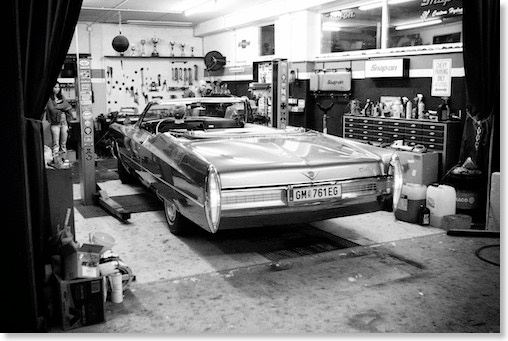

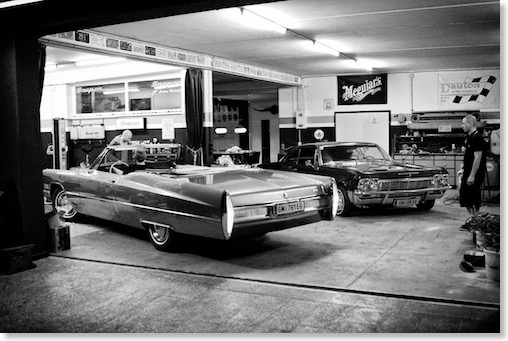

I do have two bigger projects in my garage at the moment and it looks like a mess in there.

The parts before they were media blasted.

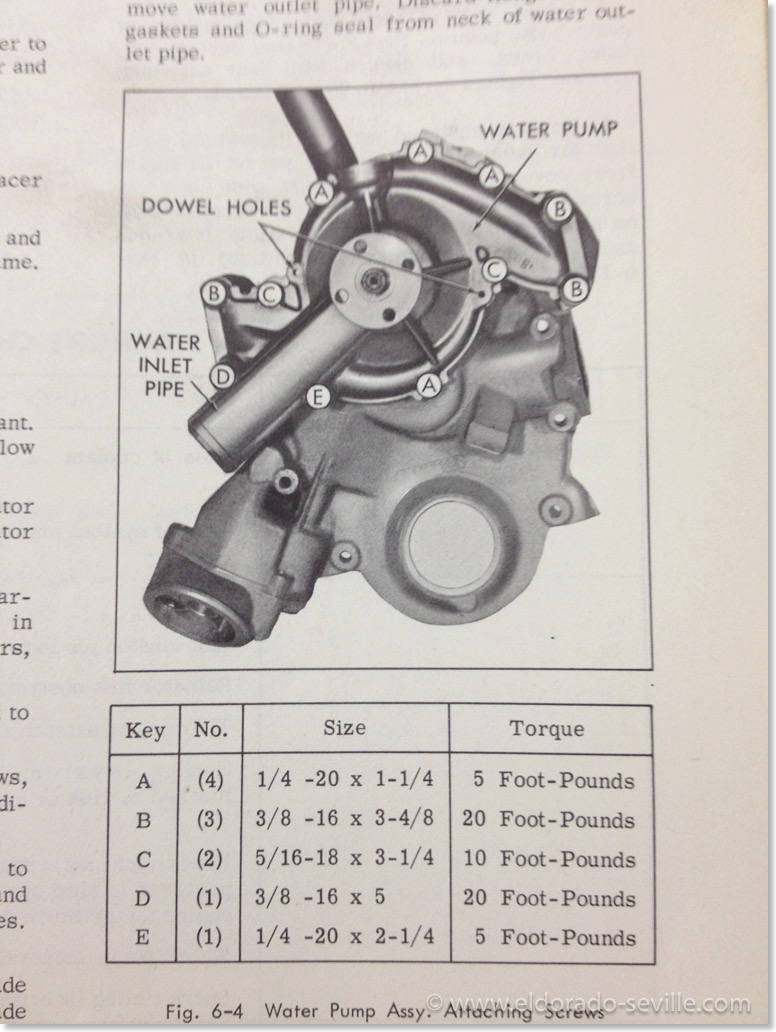

1967 Cadillac Water Pump torque specifications - make sure to follow them EXACTLY!

This is how a professional restoration shop damaged the original fuel line when it tightened it 15 years ago during a carburetor rebuild. i think I was lucky that it did not leak and still let fuel through...

I detailed the fuel lines I have from my spare engine and installed these instead..

Another construction the restoration shop made for the AC compressor bracket: - instead of rubber bushings they installed this nuts, bolts and washer construction ...

Another construction the restoration shop made for the AC compressor bracket: - instead of rubber bushings they installed this nuts, bolts and washer construction ...

I changed it back to original with the correct bolts and rubber bushings which I soaked in silicone lubricant for a couple of hours to make them soft again...

When I removed the overflow hose from the radiator the neck came loose. Luckily I found an older gentleman locally, who could brace it back together the old school way. I will of course detail the radiator as well before installing it back into the car.

I did not want to remove the front cover so I had to repaint the oil filler tube inside the car... First I brought it back to bare metal.

Oil filler tube - painted in the correct shade of Cadillac Engine Blue.

I detailed everything I removed from the car.

I primered and fillered the valve covers and sanded them to perfection before painting.

The distributor after painting. This spray gray paint from Eastwood replicates cast steel very very well. I tricked a lot of people with this paint who insisted that it must be bare metal.

I used Bill Hirsch engine enamel to paint all the engine parts.

The new water pump and the mediablasted and then repainted parts back in the car. Also painted the water pump pulley in the correct color now (black).

Most things are back together. I am still waiting for the correct reproduction radiator hoses to arrive. I did not repaint the intake manifold in the correct color as I did not have the necessary gaskets to reinstall it. I will do this eventually later, in the case that I have to remove the carburetor...

REPAIRING THE 1967 CADILLAC AC CONTROL HEAD

This time the 67 Eldorado had a new problem which I had to fix.

It suddenly only blew hot air out of the AC outlets. It did not change modes at all. That was a sign of a weak vacuum signal…

I started to inspect all the AC related vacuum lines of the car which checked out fine. Next I did the test I´m describing here in an older posting, as I suspected that the power servo had a problem.

I soon found out that still not enough vacuum was supplied through the transducer.

That meant that either the transducer could be faulty, the temperature sensor could be defective, or the dash control head would not work properly. I took out the temperature sensor of my 67 Deville to test it in the Eldorado but it did not change anything.

I then removed the control head and tested it with a spare one I once bought cheaply on ebay. It did miss some connectors and switches, it had some blemishes on the chrome and did not look good enough to install it into any of my cars. When I put it into the Eldorado anyway the AC suddenly worked perfectly again.

So I removed all the electrical parts from this working unit and transferred it to the perfectly looking but defective control head. After I had swapped all the usable parts I put the unit back into the car and I now have a perfectly working unit once again.

It looks like that there was a problem in the amplifier part which translates the signal coming from the rheostat into a current going to the transducer which regulates the vacuum going to the control head and the power servo.

Lets see what issue comes up next spring…

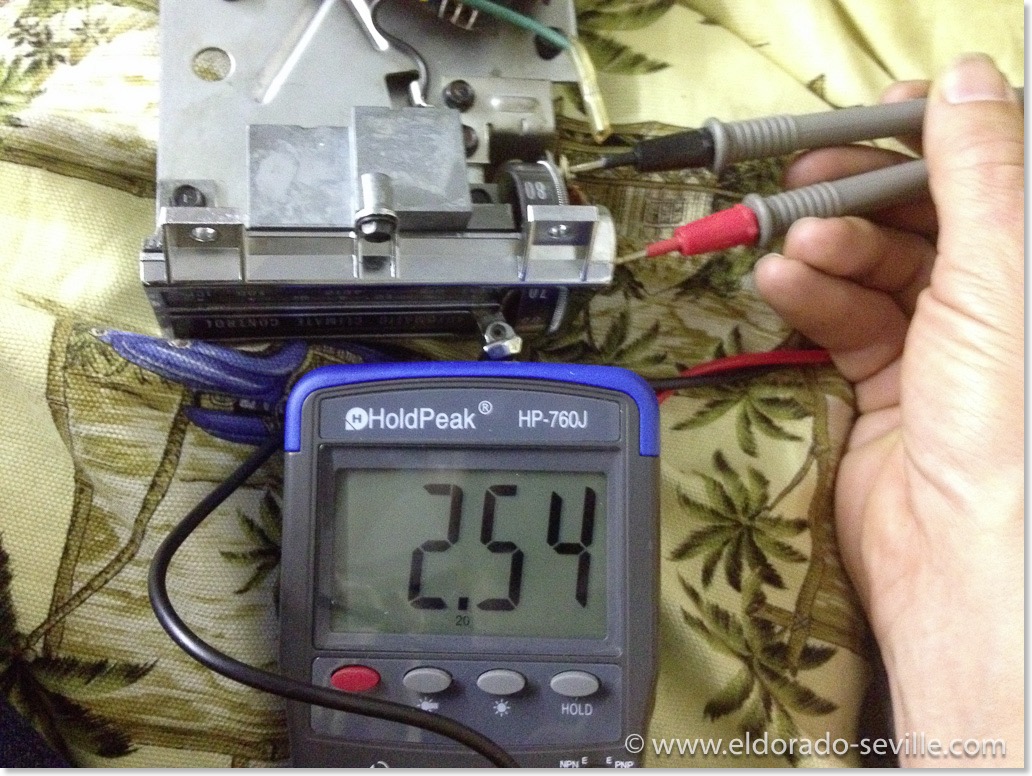

The Rheostat when set to the lowest temperature setting shows around 2,5 Ω You can check if it is working with an Ohmmeter.

At the highest temperature setting the resistance is getting lower.

The Amplifier part of the control head is on the underside. Something in here must have gone bad on my control head. I will try to find out what went bad and repair it to have a spare part.

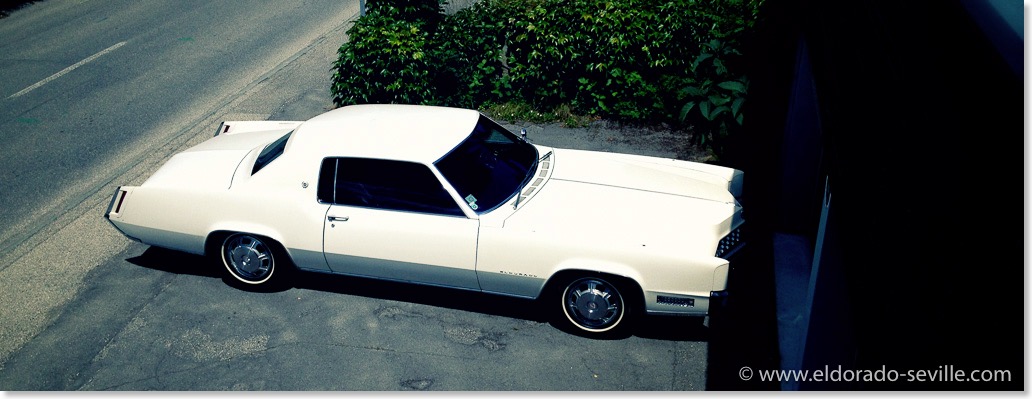

The 67 Eldorado is back on the road for the 2015 season.

1967 CADILLAC BORG CLOCKS REPAIR AND A PROBLEM WITH A PRINTED CIRCUIT BOARD.

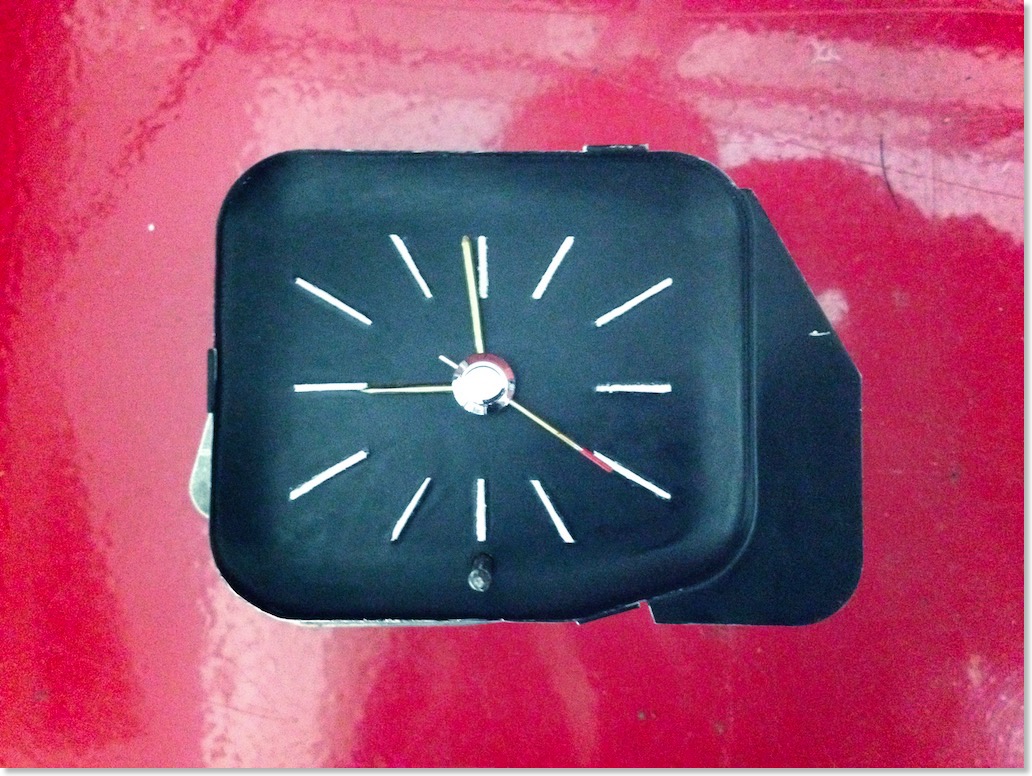

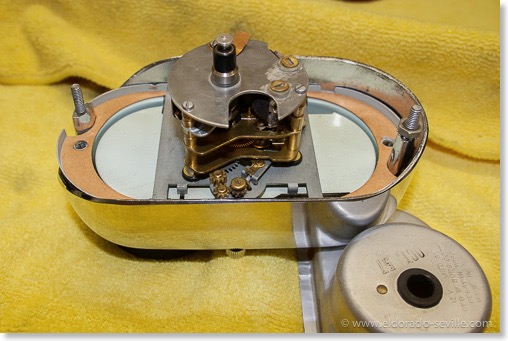

The 1967/1968 Cadillac Westclox clock out of my 67 Eldorado.

The last time I tried to repair the clock in my 67 Cadillac DeVille I totally failed. This was in 1998…

After I got the clocks in all the other Cadillacs moving again - I could no longer stand watching the dead clocks in my 67 Eldorado and DeVille.

So I decided to try to repair them as well.

The last repair attempt at my 67 Eldorado was very disappointing.

In 1998 I took the clock out of my 67 DeVille the last time, and after my repair attempt the hands started spinning in an extremely fast pace - like a ventilator. So I had to disconnect the power to the clock at the printed circuit at the back of the instrument cluster. When I did that I forgot to disconnect the battery and when the power feed touched some metal I had a short somewhere and some smoke came out of the dash… I could not locate where the smoke was coming from - all wires looked perfect. So I just insulated the clock coil power feed and gave up on the repair and forgot about what had happened.

As I found out now - some connection of the printed circuit board got burned back then…

After the failed repair of the 67 Eldorados clock last fall, I decided to try to find a good used clock. Once again Arizona Vintage Parts - my favorite source for parts - came to the rescue. He sold me two non working Borg clocks for a really good price. Unfortunately by now he has run out of stock for them.

So I tried to repair the clocks he sent me - appearance wise they were in very good condition, and I got one back to life for a short time by just cleaning it.

So I put it back into the car and then I made a stupid mistake and ruined it completely. I wanted to tighten the mounting screws and accidentally grabbed the connector for the coil - as you have to work inside the dash without being able to see what you are doing - and so I overtightened it… This stripped the threads of the coil… I had to cut the nut off then and somehow the oscillator wheel inside the mechanism did no longer work properly and when I tried to adjust the stepper it broke off :-(

BTW - Do not use WD40 for cleaning and lubricating a clock like I did… This will ruin the clock as I found out when it was already too late… There are special clock oils available to lubricate clocks.

The other clock I got had a defective oscillator wheel and I could not repair it as well…

So I contacted Arizona Vintage Parts once again for some new clocks but he had sold all his stock on clocks to Sweden…

I had to contact all the Cadillac Parts dealers I found in Hemmings Motor News for two Borg clocks, but I was unsuccessful or they were exorbitantly expensive. Some of the well known Cadillac Parts dealers either did not have them, did not react to my inquiries or asked up to $ 385.- for a used, rebuilt clock. Others asked up to $180.- for a non working clock.

Luckily I found a company called “The Clockworks" which was highly recommended on some Cadillac and other classic car forums for their good work in repairing clocks and also converting them to a quartz movement.

Everybody seems to recommend to convert your clock to a much more reliable and cheaper quartz movement. I thought about it for a while but I decided that I wanted to go for an original movement for authenticity reasons. If you convert to quartz the "tic-toc" movement will be gone and you can tell by just looking at the clock…

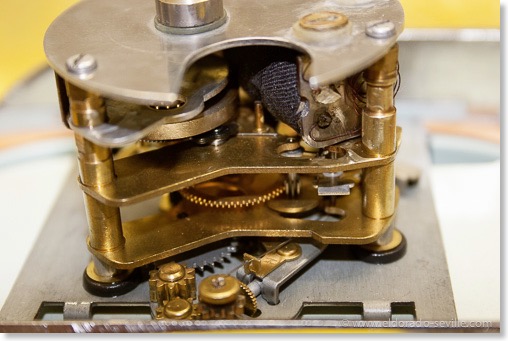

I ordered two rebuilt Borg clock movements for my clocks from "The Clockworks". Their service was excellent and they were a great help. Great customer service! I would buy from them again or have my clocks rebuilt by them anytime.

After I received the movements I installed them and put everything back together. You have the keep the adjustment stem and the housing from your old clocks if you replace the movement.

When I put the clock back into the 67 DeVille it did not work though. I soon found out that no power was coming to the coil through the printed circuit board.

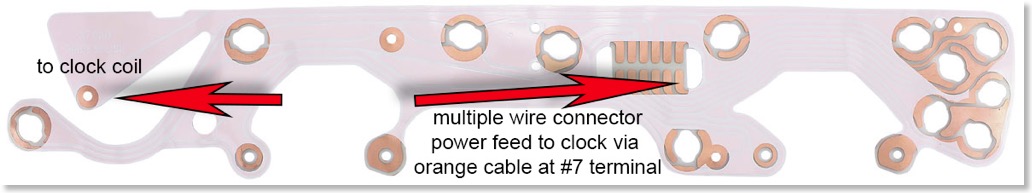

I then remembered about my failed repair attempt 17 years ago and the smoke that came out of the dash… Somewhere the circuit board was burned. So I connected the orange cable going into the multiple terminal connector at #7 terminal to the clock directly and it worked again.

So I installed a cable directly to the clock. This is a temporary fix until I´ll have a new circuit board. Installing a new board requires to take the dash completely apart to replace it.

A printed circuit board is available new here: https://www.opgi.com/cadillac/CE11091/

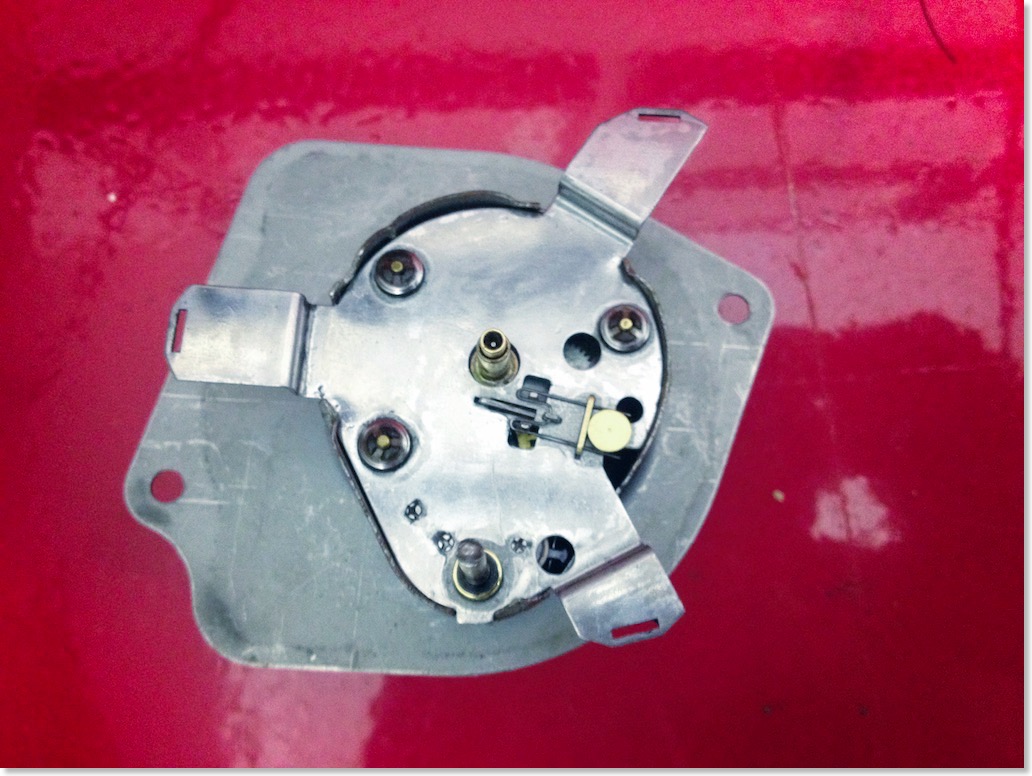

The 1967 Cadillac Westclox clock out of my 67 Eldorado. Seen from the top with the clock face removed. The clock face on the Westclox is mounted differently than on the Borg.

The 1967 Cadillac Borg clock. The housing cover in place - as you can see it looks completely different than the one on the Westclox.

The 1967 Cadillac Borg clock out of my 67 DeVille.

The Borg replacement clock I got from Arizona Vintage Parts.

The Borg replacement clock I got from Arizona Vintage Parts - this is the original movement removed from the housing.

The rebuilt Borg movement I got from "The Clockworks"

There is a difference in the second arms: On the left the one from a Borg Clock - on the right one from a Westclox. They are not interchangeable. Also the housing of the clocks is different. You cant interchange parts between these two clock types.

I repainted the setting stem in semi gloss black.

The 1967 Cadillac printed circuit. The one for the Eldorado is slightly different though.

REPAIRING THE CLOCKS OF THE 1958, 1966 AND 1967 CADILLAC

So it was time to service some of the clocks which stopped working over the years.

The clock in the 66 did not work at all.

It's extremely simple to remove on the 66 as you can get it out of the instrument panel by just unscrewing one bolt.

The clock was very dirty in the clock work and needed a good cleaning and some good lubrication. Also the contact of the coil was a little worn and this was fixed. It then happily ticked back to life and now works perfectly.

The clock on my 58 stopped working a couple of years ago. So it came out as well. It's a little more complicated to get it out though...

When it was finally out - it could be seen that the coil was burnt and that it needed some very good cleaning as well. Some of the melted insulation material was all over the clock mechanism and of course I had no spare coil for it - so the original one had to be rewound with some good wire from a left over light solenoid...

Wow - this really took a while - but now the clock works perfectly again!

I was not so lucky with the clock on the 67 Eldorado which only worked when the car was warm. To take it out you have to remove the upper dash and then get out some light bulbs and disconnect it from the printed circuit.

It was also cleaned and lubricated and the clock worked, but it made a very loud noise when the coil rewound the spring of the clock.

The sound got better over night, but then the clock stopped working completely... It's a Westcox clock which uses a double coil and is much more complicated to rebuild than the Borg clocks. Its also almost impossible to find parts for it, as Borg clocks are much more widely used.

Looks like I will need a new 1967 clock and replace it with a Borg unit :-(

The clock in the 66 is now working perfectly again.

The disassembled clock of the 58 Eldorado.

The coil was burnt on the 58 clock.

Fully cleaned clock.

Back together with a rewound coil.

Back in the car - working perfectly again.

Front wheel bearings replacement on my 1967 Cadillac DeVille

As we had the first really warm and sunny days this weekend, I took the car out of storage and put it into my old garage to do the work. It's a pretty easy job on the 1967 Deville - you do not even need any special tools or presses.

I got a set of inner and outer wheel bearings for both front axles from Rockauto.com - I got a set made by “Moog“ as I have heard good things about their quality.

You just have to remove the tires, remove the pin at the axle, remove the big nut and pull off the brake drum. The outer bearings can just be pulled out - the inner bearings have to be tapped out with a long screwdriver, as they are held in place by a dust cap. A very slight tap is all it needs to get it out. I cleaned everything and put the greased new wheel bearings in and put everything back together. I also readjusted the front brakes and also found that one of the new brake hoses was a little loose and loosing a little brake fluid, so I tightened it.

As I had the front wheel tires off the car - I also cleaned the entire front suspension and detailed it. Everything is squeaky clean now again. No more noise is coming from the wheel bearings now…

The old inner wheel bearing is out

The new inner bearing

There is a dust cap which you have to tap out

the front axle

Back together - before detailing the wheel housing and front suspension

Outlook to the 2012 season - doing the first repairs 2012

The following work is planed for the next few months before the cars will be put back on the road in May 2012.

1971 Mark III

- new vinyl roof (the original one was damaged during transport and the insurance will pay for a new one)

1967 DeVille

- needs new front wheel bearings (I already have the spare parts)

- will try to find a rebuilt OEM Bendix master cylinder and vacuum booster. These are very difficult to find. Everybody seems to offer Delco Moraine parts only. I have replaced my original booster and master cylinder 2 years ago and I´m not quite happy with the power assist of the new units. It seems that the after market master cylinders from Delco have a smaller bore diameter and therefore you will have to depress the pedal with more force. There is a discussion going on on the topic of finding the correct booster and master cylinder in the CLC forum - check it out for more detail! If you know where I could find a correct Bendix booster and master cylinder or where I could get my original core rebuilt, please let me know!! The parts number for the Bendix Master Cylinder is #1489981 and for the Bendix booster it is: #1489071

- re-adjust the gear indicator as it's slightly out of line.

1967 Eldorado

- I will remove the starter motor and have it rebuilt - it sometimes is acting up

1958 Eldorado

- It needs some new front wheel bearings as well. I already bought the parts.

I will of course post the repair progress here on my website

A new garage?

The biggest planned project for 2012 will be to find a solution for my storage problem. I hope to be able to build another garage or to rent one. I will have to find a solution until the spring of 2012. I´m dreaming of building a building which can hold 8 Cadillacs, but I do not know yet if I will be able to afford it...

Car Shows

I hope to attend and visit the „Klassikwelt Bodensee“ from May 17th to 20th and of course the best meeting in Europe - the Cadillac BIG Meet August 25th to 26th. I will also hopefully make it to some local shows here in Austria.

As we had a dry winter day I took the cars out of the garage - they fired right up after some months of sleeping

The Mark III was moved to the back of the garage, so that I can start working on the other cars first

Little Elliot loves Daddy´s cars as well ;-)

Replacing the rear shocks on the 67 DeVille

The right shock came out pretty easily and as planned - it was great to work with Richards awesome collection of tools he has in his workshop. I could not help my friends as much as I would have liked as I had snapped one of my ribs two days ago while changing tires and so I cant even hold a wrench properly at the moment... So my great friends did most of the work for me.

As it turned out the new Monroe shocks I had bought were delivered with one wrong bolt - the other 3 bolts were correct though. Fortunately I had a correct bolt as a spare from another set I had bought. When we wanted to take out the left shock we ran into a problem with the top bolt which would not want to loosen up. Its also pretty difficult to get access to it - as it is hiding behind the curve of the exhaust pipe. After 1,5 hours of sweating and bad cursing it finally gave up due to the help of a heavy duty metal saw. The new left shock went in pretty quickly afterwards but then it was already 1 am.... Thank you my friends for your great help and support!

At work in Richards garage around midnight... In the background Richards 65 Impala and Alex´s 63 Riviera in the front...

Unpacking the new shocks

Richard and me at work

Unscrewing the old shocks

Figuring out how to mount the new Monroe shocks...

the left shock just did not want to come out...

Backing out of Richards garage...

The 67 Eldorados new POA valve and recharge of the AC

I got a new remanufactured POA valve (suction throttling valve) from Classic Auto Air to make sure that the system can cope with the much higher pressures of R134. Classic Auto Air was very helpful with providing the factory correct parts. Classic Auto Air says that the re-calibrated valve can make a 15-20º F / 6º C difference.

Yesterday I got the Eldo back from the shop and so far it seems to cool the car down properly. The air discharged out of the vents is 10º C / 50º F cold - not bad for R134.

This is what Classic Auto Air is recommending for a change from R12 to R134:

Minimum Requirements

- Change or restore the filter-drier.

- Drain the compressor oil and recharge with 134a compatible oil. (PAG or Ester Oil)

- Insure that the system is clean and free of contaminants (Depending on component condition, this may be a simple matter of blowing out with compressed air or liquid flushing with an air-conditioning flushing agent)

- Replace or restore all rubber hoses with barrier hose.

- Install 134a charge port adapters

- Send POA valve in to be calibrated

- Charge with 134a between 70-80% of the original R12 charge amount.

- Replace any o-rings with 134a compatible

Recommended:

- Install hi/lo pressure switch

HELPFUL HINTS

- Ignore the sight-glass. A properly charged 134a system will likely show bubbles in the sight-glass.

- Typical 134a charge rate will be approximately 70-80% of the factory R12 charge amount.

The new factory correct POA valve. Internally it was calibrated for the use of R134 instead of R12. The expansion valve was also replaced together with the evaporator, condenser, compressor, O-rings, filter-dryer. I did not install a hi/lo pressure switch which would cycle the compressor on and off to keep the car original.

THE 1967 CADILLAC AUTOMATIC CLIMATE CONTROL SYSTEM - MORE ISSUES - AND A FINAL FIX? RESTORING THE POWER SERVO VALVE!

The 67 Eldorado lost its complete charge of refrigerant over the winter - so it will have to go back to the shop to see where it is leaking. All components were replaced with new ones last year and so I have no idea where it could have leaked out. A tracer was put in before the last recharge so we should be able to find the leak. I guess that it will be one of the original hoses are a bad fitting.

Another thing that bothered me was that the system basically worked most of the time, but sometimes I had to wait for a long time before the system came on, or I had to switch to “FOG“ or “ICE“ position before the blower would come on in the “Auto“ position. Then sometimes the blower would cut out again if the temperature dial was moved to a colder temperature. Sometimes the temperature would move to full heat regardless off the selected temperature in the 67 Eldorado.

I had the very same problems on my 67 Deville as well - but there also the “Vent“ and “Low“ position did not work at all...

So I started trying to find the issues and finally wanted to fix them. Sounded easy - but it took me 4 full days with long nights in the garage to fix it...

BTW - Cadillactim has an excellent trouble shooting guide for the ACC on his website - its for sale for $ 45.- and I can highly recommend it if you are troubleshooting your 1967 or 1968 Air Condition System.

A great troubleshooting guide for 1967 and 1968 Cadillac´s Automatic Climate Control Systems I got from Gary Sisk - owner of a 1968 Cadillac.

This is a very easy to follow explanation which will save you a lot of time and you do not even need any special tools.

It was written by Lynn Nicholls and can be found on Stampies Cadillac page - here is the direct link to it. I used some excerpts from his document in the explanation below:

I first suspected a vacuum leak to be responsible for most of the erratic behavior of the system. A clear indication was that the system would initially have to be switched to the “ICE“ position to make the blower come on.

Lynn Nicholls writes:

“Sometimes the dash control can be switched to the fog or ice positions to bring the blower motor on and then when it is switched back to auto the blower may stay on and the system seems to work fine until the car is shut off. If the vacuum leak is only moderate there may be enough vacuum to hold the master switch closed once it gets , but not enough to pull it closed in the first place. When the dash control is switched to fog or ice, it assumes the air temperature is cold and that the engine is not yet warmed up, but that the blower is needed immediately for defrosting the windshield. So it supplies vacuum to the master switch through another circuit, bypassing the temperature controlled vacuum switch on the heater core shutoff valve on the right fender well. This source of vacuum is enough to close the master switch.When the dash control is switched back to auto this vacuum source is shut off, but there may be just enough vacuum left from other circuits to hold the switch closed. This routine will work for a while but as the leak gets worse, there won’t be enough vacuum left to hold the master switch closed anymore and the blower will shut off again as soon as the system is switched back to auto.With these symptoms and behavior the problem is most likely the power servo. This is half the brains of the system; the other half is the control panel in the dash. The power servo is controlled by a varying vacuum signal from the transducer. This vacuum supply is a completely separate circuit from that which supplies vacuum to the master switch. High vacuum moves the servo to the maximum heater position, and with low vacuum, a return spring moves it to the maximum AC position. In between these two extremes, it regulates the air temperature door to blend warm air and cool air, and simultaneously regulates the blower speed. It also spins an internal rotary vacuum valve back and forth that makes various connections between the several small vacuum lines on the top. This rotary valve controls the various vacuum motors of the system that operate the AC, heater, and defrost functions. It is this rotary valve that goes bad. l have seen these things visibly warped, and very badly so. It must be caused by engine heat, because there is also one inside the car on the control panel that is moved back and forth by the dash control lever, but that one seldom seems to cause any trouble. A warped rotary valve leaks all kinds of vacuum and the first part of the system to be affected by low vacuum is the master switch; there’s not enough vacuum there to close it and turn on the blower. To verify this is the problem, take some spare vacuum line, some scraps of 1/8 inch pressure line (like for air shocks), and a vacuum T and manually make the connections that the rotary valve should make in the maximum AC position. The connections that the rotary valve makes in various positions are shown in the factory shop manual. Disconnect the black connector with the striped vacuum lines from the power servo. Connect the yellow, red, and purple lines together with a T; also connect the tan and blue lines together and connect the orange and green lines together. If this rotary valve is the one and only culprit the AC will now work beautifully and the blower motor will come on every time, like magic. With the dash control on high the system should be recirculating air and there will be a lot of air noise coming from under the right side of the dash; when the dash control is moved to auto the air door should move to provide fresh air and the system will become much quieter. Of course with these manual connections the system is not fully automatic and the heater won’t work right at all, however this is enough to diagnose the problem.“

I did this test (see picture below) - and with the power servo bypassed everything worked as it should. This way I knew that the power servo was to blame for some of my problems.

So this rotary valve needed to be repaired...

I removed it from the power servo and disassembled everything.

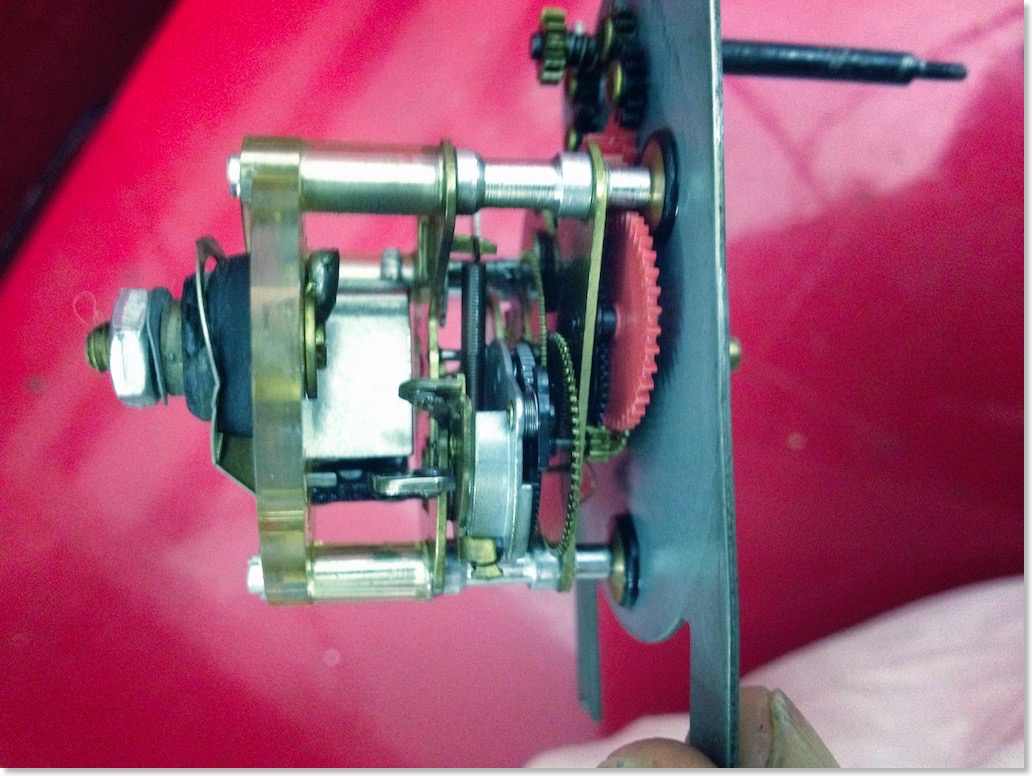

The removed power servo

After opening the cover, you can see the rotary valve in the lower center.

Remove one screw and a clip and the rotary valve comes out.

The rotary valve consists of two halves which make the connections - as you can see it was very dirty and rough - and slightly warped.

I started to wet sand both halves with 800 grit sandpaper.

When everything was flat and shiny again I used some 2000 grit sandpaper for a perfect finish.

Looks shiny and flat again

Make sure that none of the ports are clogged - I used compressed air to clean everything.

When you put the two halves together lubricate with WD40 to make sure that when you put them back into the power servo that they are properly held together with the underlying spring.

After I reinstalled them into my cars - almost everything worked as it should. In the 67 Eldorado I still had the problem that in the “AUTO“ position the fan would always be slow - so I knew that the control head in the dash had a problem with the “LOW - AUTO“ switch as well.

In the 67 DeVille the “VENT“ and “LOW“ position still did not work at all...

So I switched the control panels between the two cars and suddenly everything in the 67 Eldorado worked perfectly. I never had such a perfectly working system before. Its like it just left the factory!

In the DeVille I still had no “VENT“ and “LOW“ settings working... So out came the control panels again... (its a pain in the a*** to remove and install them...)

As it turned out the “LOW-AUTO“ switch on one panel was stuck in the “LOW“ position. You can easily remove it and readjust it to work again - sorry I forgot to take pictures. Make sure that all switches on the control head are adjusted properly or they wont work as they should!

So I knew that both control heads were working correctly by installing it back to the 67 Eldorado and the other panel back to the 67 DeVille.

While the 67 Eldorado was perfectly fixed now with everything working as it should - the 67 DeVille was still giving me the problem with a non working “VENT“ position...

I studied the shop manual for hours and could not find what the problem could be. I knew that the power servo was working perfectly now and I knew that the control head was in perfectly working order as well. I verified this once again by switching these parts between the cars once again and everything worked as it should in the Eldorado but not in the DeVille.. I´m really good in switching these parts between my cars now ;-)

I started to look for electric connection problems and finally found out that no electricity was coming out of one of the three power servo connectors, but I did not know why...

After I removed the power servo once again to re-check it again it struck me - one of the pins was slightly bent and the wire connector did not make proper contact. This problem was not visible with the power servo installed in the car. It took me 2 long nights to find this little flaw... I just bent it straight and everything works as it should on both of my 67 Cadillacs. Now I have to recharge the systems and I should have perfectly working AC again... I will also install new dryers and a re-calibrated R134 POA valve before the recharge.

One the one hand the 1967 ACC is very complicated but once you know how it works its pretty easy to fix. The rotary valve in the power servo is pretty easy to refurbish, the dash servo valve is riveted together unfortunately, so its not such an easy fix, but NOS valves are still available at “Classic Auto Air“

*UPDATE 2022* - Check out this article and video as well as I had to repair my switch again in 2022 on my 66 DeVille!

Here is a video about the Master Switch that a gentleman posted on youtube

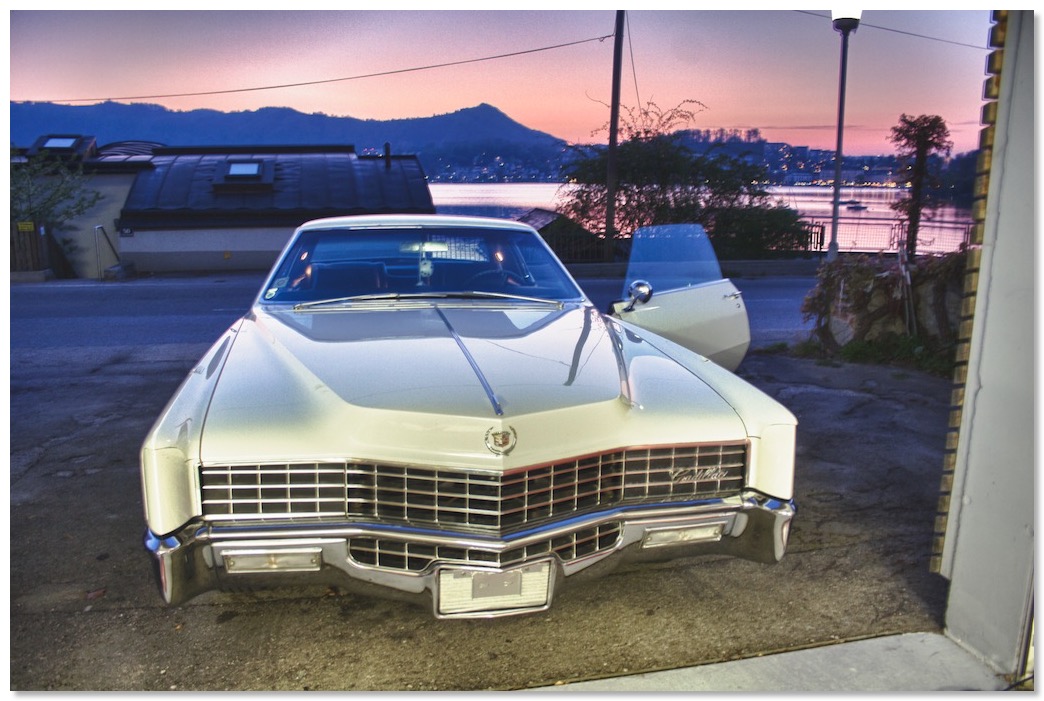

The 67 Eldorado in front of the garage after the AC system was fixed.

1967 Eldorado Seat Transmission repaired

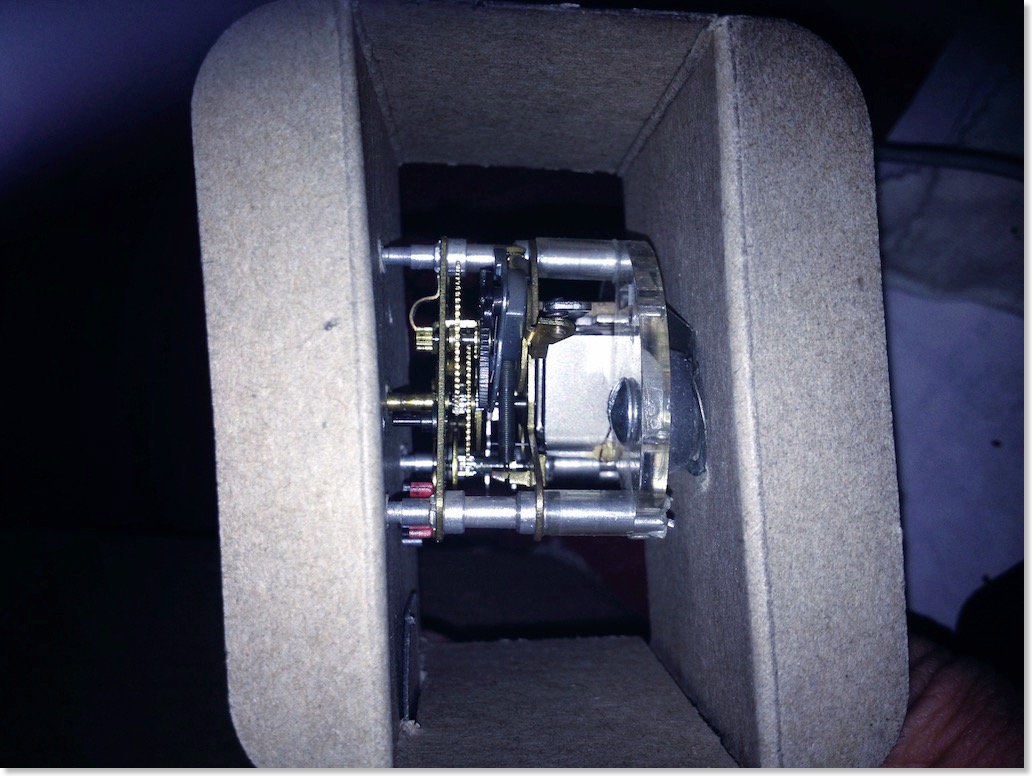

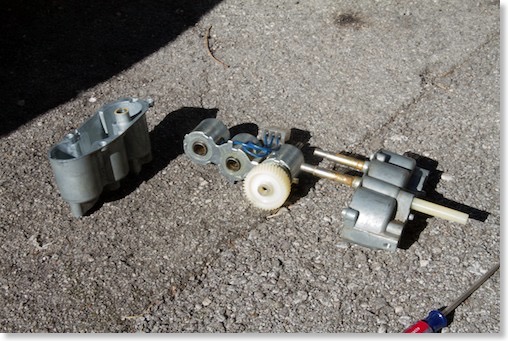

I removed it from under the seat, what was a little tricky and involved getting in some strange positions to access all the screws. It would be easier if one removes the seat from the car, but thats a rather unpleasant work as well...

Eventually it came out of the car. I disassembled it and at first everything looked pretty good, but it soon showed that the old grease became rather hard and sticky and one of the three solenoids was no longer able to push the gear into a locked position.

I thoroughly removed all of the old grease and re-greased everything with white lithium grease. I then reassembled everything, reconnected the gear cables, reinstalled the transmission under the seat (thats a very tricky part...) and everything worked like new!

I now have perfectly working power seats again!

The seat transmission disassembled - you can see the brownish old grease everywhere.

Part of the gears and the solenoids

The transmission part

The three solenoids

The cleaned and re-greased transmission

The 67 Eldorado´s Automatic Climate Control System is back in working order

I suspected a vacuum leak somewhere in the system. Troubleshooting began with going through all the vacuum hoses. I replaced some which were a little worn out at the connectors. I also cut off the ends of most hoses, as they were all becoming a little loose during the last 40 years. I then plugged them in again.

Not much did change though.

When I came to the hose of the hot water valve and the delay relay, I had the first success. At least the blower motor would stay on in all “Auto” modes, even when the car was idling - but would still go off in “Fog” and “Ice”. I then suspected a leak in the power servo or in the dash controller. So I installed the power servo from my 67 DeVille where everything works perfectly, to be able to rule out any problems. Nothing changed though - the blower would still come on and off depending on the throttle position.

I then soon found the culprit of the whole issue - it was the master vacuum switch - which seems to have a problem with the internal electric switch. As I had a spare one around I installed it - and voilá - everything worked as it should. It always looked good when I checked it before.

I´m very happy that everything is back in working order. The only thing which I still have to repair is the fast idle diaphragm which completely dried out and is no longer functioning. Fortunately I do have a spare 429 engine in the garage from where I can grab and use this part - so I will repair it soon.

I then need a new condenser which is already on the way across the Atlantic coming from Old Auto Air.

By the way - Cadillactim has an excellent trouble shooting guide for the ACC on his website.

The evaporator had to be replaced as well along with the heater core. This is a pretty big task as you can see on the pictures below. You even have to remove the hood to get access to the whole unit. The fiberglass AC enclosure had to be repaired at my car as well as the previous owner tried to repair the evaporator and missed a screw and made a tear into the enclosure. The restoration shop repaired this professionally and it looks like new now.

The best troubleshooting guide for 1967 and 1968 Cadillac´s Automatic Climate Control Systems I got today from Gary Sisk - owner of a 1968 Cadillac.

This is a very easy to follow explanation which will save you a lot of time and you do not even need any special tools.

It was written by Lynn Nicholls and can be found on Stampies Cadillac page - here is the direct link to it.

Below you can find some pictures of my system:

The whole AC unit has to be removed to get access to the evaporator and heater core... The slight surface rust that showed up where the gaskets were, was removed as well of course...

The big hole on the left is where the blower motor is installed.

This is where the AC box usually is installed

You can see how much has be removed just to get to the evaporator and heater core...

I discovered the first issue at the hot water valve

The hoses around the time relay delay were leaking a little bit

For testing purposes I hung a spare master vacuum switch into the car - this solved the problem

The old fast idle diaphragm was leaking and brittle and was replaced with a better one...

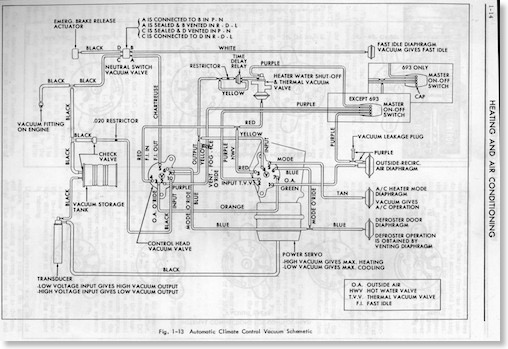

The 1967 Cadillac Automatic Climate Control Vacuum Schematic from the shop manual -

1968 is almost identical BTW... Click on the image for a larger view!

Here is a video about the Master Switch that a gentleman posted on youtube

67 DeVille Brakes finally fixed

As I replaced the complete front end including the entire front brakes last year, I did not think that the drum brakes might only need a simple re-adjustment. As it turned out the front brakes were out of the range where the star-wheel can adjust itself while driving the car backwards and applying the brakes.

I now adjusted the front brakes pretty tightly and the pedal is now pretty firm again. I hope it will stay like this. If not - there must be something wrong with the automatic self adjuster, but I´m very optimistic that the problem is now solved. I also gave the rear drums a check - they turned out fine. I just wished the DeVille had front disc brakes like my 67 Eldorado...

checking the rear drums - crappy cell phone picture...

the rear drums

1967 DeVille got new brake booster and power cylinder

Everything went pretty smoothly at first - only bleeding the brakes was a little complicated and it did not help either that I spilled some brake fluid into the engine bay. Some harm was done to the black paint which had to be repainted immediately. So it took us some unplanned time to get everything back in working order. As it was raining heavily we could not even test the brakes. In the meantime I did a test drive and found out that the pedal travel is way too long. Looks like the push rod in the booster needs adjustment... D*mn this means removing the master cylinder once again... I hope I will find the time to do this soon.

the removed brake booster - the hole in the firewall

the new booster needed some paint before installation

painting the master cylinder

Tayfun painting the primered booster

reinstalling the whole unit

Tayfun bleeding the brakes

finished - looking good

Detailed seats are finally back in the 67

If you compare the new pictures to the “before” pictures below - you can clearly see the difference.

Thats the area which showed the most wear - looking perfect now!

the same area before detailing

the interior is back together and now waiting for the cruising season

Leather seats are back from detailing!

They look like brand new leather seats now!

the front seat before

the front seat now - before installation

the rear bench before the repair

after the repair - all the tears and cracks are gone!

The 67s interior is going to the detailer.

this is one of the areas which will be restored - its showing some surface age cracks.

my wife Afra helped me removing the seats

the removed seats

I had to drive the car back into the garage sitting on the floor...

1967 Cadillac turn signal switch arrived

UPDATE 2010: In the meantime (since 2009) the Boyne switches they are getting reproduced and show up on ebay all the time. Also OPGI shows them in their Cadillac catalog. Its harder to find one for a T&T column as they are not getting reproduced so far. I do not know where one could find a switch for T&T though. If you know of any resource for T&T switches please let me know, I would love to have a spare one for my Eldorado!

When I was looking for a switch for my 1967 Deville, I only investigated resources for cars without T&T columns and this is what I found out:

According to the 1971 parts manual there are two different ones for standard column cars and one for T & T

- 1967 - 1968 (Exc. T & T) Part # 7800483 - Switch, w/wiring harness (Delco-Remy)

- 1967 - 1968 (Exc. T & T) Part # 7805675 - Switch, w/wiring harness (Boyne Products)

- 1967 - 1968 (T &T) Part # 7805676 - Switch, w/wiring harness (Hazard warning switch an integral part)

The two different standard column switches can be identified without removal as the parts manual describes:

„Hazard warning switch is an integral part. Switches can be identified before disassembly as follows: The Delco Remy switch has a square hole for the hazard warning switch in the cover, the Boyne Products switch has a round hole for the hazard warning switch in the cover.“

The problem with the switch on my standard column DeVille was that the return cancel cam broke, and that non of the repair kits were available for the Boyne switch.

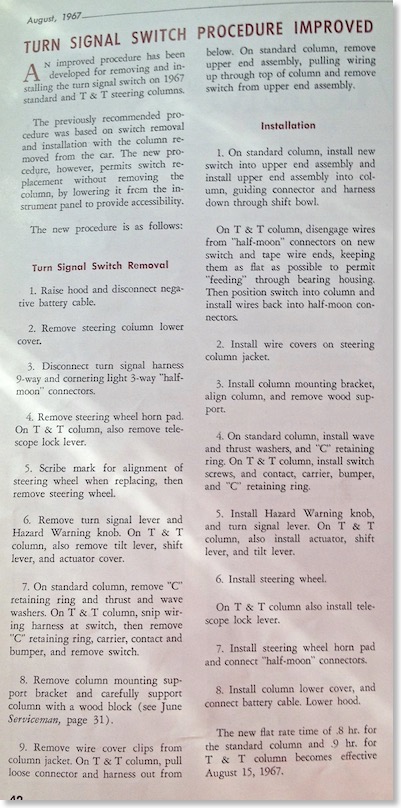

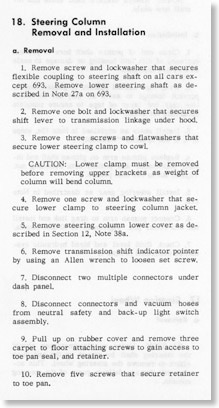

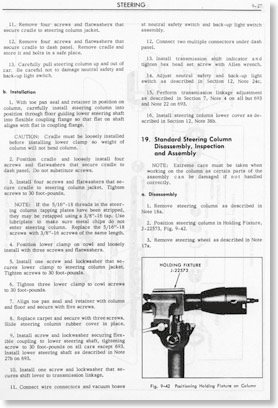

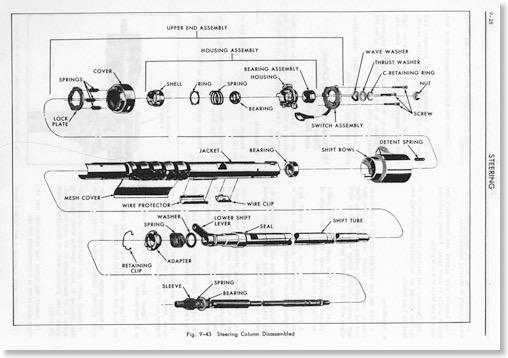

Replacing this switch in the steering column is quite a pain - below you can find the instructions from the shop manual on how to do it.

There is also a revised procedure for a much easier installation below in the “Cadillac Serviceman" from August 1967!

Click on each picture for a larger view!

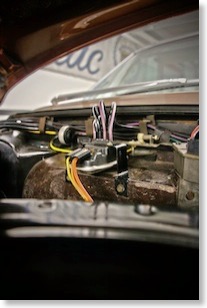

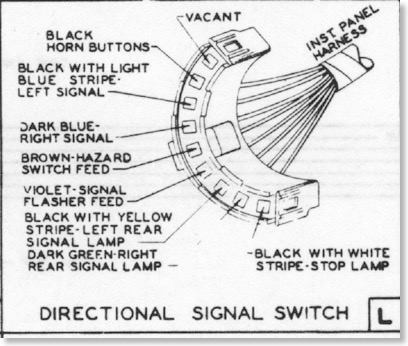

The connections going to the directional signal switch - the turn signal switch connector

The Cadillac Serviceman from August 1967 shows a revised procedure for a much easier installation of the switch.

If you need the shop manual instructions for a tilt and telescope column click here! Or just use the procedure above!

Cleaning the 67´s front suspension

The brakes before I disassembled them - I hope I can clean the small metal parts with an ultrasonic cleaner

All these parts will be sandblasted and painted afterwards

The 67´s front suspension

After this the suspension will be in new condition - one of the last things that have to be done on the 67 before it is really in like new condition.

The only other thing which will need attention in the future will be the top which is still the original 40 year old one, but is still a little to good to be replaced…

The 67 is in the shop...

Later I also dropped off the 67 there as some smaller things have to be repaired as I do not have the necessary tools nor skills to do them myself.

- The front-suspension needs a rebuild and I do not have the presses to push some of the bushings in and out.

- The switch for the directional switch in the steering column has to be replaced

- Need a new ignition lock

- The transmission has some leaks I could not find

The guys from who helped me with the restoration of my cars will take over.

In a couple of weeks I should have the car back. It will go directly into winter storage then. Today also was the last day to drive the 58. I will return the plates over winter.

AC Problem

Three parts could cause this problem:

- The dash switch with its rotary valve from where I can hear a slight hissing noise,

- the power servo on the firewall

- or the master switch itself - what I doubt.

As I hate when something does not work on my cars I ordered all the parts. I found a good source which sells all these parts rebuilt. Hopefully they will arrive soon as I would like to have this issue resolved before the Cadillac Big Meet. It should not be too much of a hassle to install them when they are here.

The power servo

The power servo and master switch

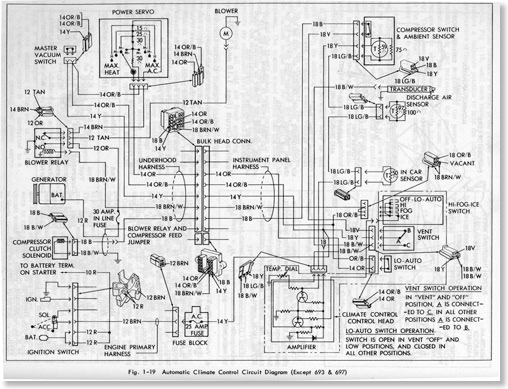

The electrical circuit of the Air Conditioning system of the 1967 Cadillac DeVille in a digram

Here is a video about the Master Switch that a gentleman posted on youtube

67 gets new fuel filter

Eventually I made it and when everything was back together, the bowl leaked. So I had to re-open everything. I readjusted the gasket and now everything is tight. The old filter was very dirty, because at the last big service I forgot to replace it...

1966 Cadillac Coupe deVille (16)

1967 Cadillac DeVille (54)

1967 Cadillac Eldorado (73)

1971 Lincoln Continental Mark III (24)

1974 Cadillac Coupe deVille (46)

1978 Cadillac Eldorado Biarritz (25)

1996 Buick Roadmaster (20)

Cadillac BIG Meet (2)

Car Shows (55)

Cruising (4)

CT6 (1)

For Sale (3)

Garage Stuff (32)

Pacer (1)

Restoration (140)

Various (55)

Video (20)

Website News (31)

- 6 way power seat

- 8-track

- 10 Ohm

- 429

- 1932

- 1957

- 1958

- 1958 Cadillac Eldorado Seville

- 1958 Cadillac Repair Tip

- 1959 Cadillac Eldorado Seville

- 1964

- 1965

- 1966

- 1966 Cadillac Coupe deVille

- 1966 Cadillac Repair Tips

- 1967

- 1967 Cadillac DeVille

- 1967 Cadillac Eldorado Repair Tip

- 1967 Cadillac Repair Tip

- 1967 Eldorado

- 1968

- 1970 Cadillac Eldorado

- 1971

- 1971 Lincoln Continental Mark III

- 1974

- 1974 Cadillac Coupe DeVille

- 1974 Cadillac Repair Tip

- 1976

- 1977

- 1978

- 1978 Cadillac Eldorado Biarritz

- 1978 Cadillac Repair Tip

- 1980 Cadillac Eldorado Biarritz

- 1996

- 2012

- 2014

- 2017

- 2018

- 2019

- 2022

- 2023

- 2025

- 3063206

- 7027235

- 7800483

- 7805675

- 7805676

- 12355706

- 17058531

- 17059968

- 17059969

- 22010515

- 22010661

- A.I.R

- A6

- AC

- AC Compressor

- AC Electrical Diagram

- ACC

- Accelerator Pump

- Accelorator pump

- Accident

- Actuators

- Adriatic Blue Metallic

- Ads

- Aftermovie

- Air Pump

- Aircondition

- AIRPUMP

- ALC

- Alternator

- AM

- AM-Transmitter

- Antenna

- Anti Rattle Clips

- Antique Gold

- Arizona Vintage Parts

- Arrival

- Article

- ASC

- Ash Tray removal

- ATC

- Atlantis Blue Firemist

- Austria

- Austro Classic

- Autolite SP-459

- Automatic Seat Back Release

- Award

- Banner

- Barn Find

- Battery

- Battery Tray

- Beach Race

- Bearing

- Bendix

- Biarritz

- Bigfoot

- Bill Hirsch Engine Enamel

- Bleeder Screws

- Bleeding

- Blower

- Bodywork

- Bolts

- Book

- Borg

- Brake Booster

- Brake Fluid

- Brake Gray

- Brakes

- Broken Bolt

- Brougham

- Bucket seats

- Buick

- Bumper End

- Bushings

- Cadillac

- Cadillac BIG Meet

- Cadillac BIG Meet

- Cadillac birthday cake

- Cadillac Blue

- Cadillac Color Selections Dealer Book

- Cadillac Coupe deVille

- Cadillac Dealer

- CADILLAC GRAND EUROPEAN

- Cadillac Meeting

- Cadillac Mini Meeting

- Camaro RS

- Caorle

- Car Show

- Carburetor

- Card

- Carpet

- Carter AFB

- Cavalry Twill Vinyl

- CB

- CBM

- CCCD

- Choke

- Christmas

- Citizens Band

- Classic Cadillac Club Deutschland

- Clay Towel

- Cleaning

- Clock

- Clockwork

- Clutch

- Clutch Coil

- Collector

- Colonial Yellow

- Color Coded Springs

- Commercial

- Compound

- Compressor

- Condenser

- Continental Mark III

- Control Head

- Conversion

- Convertible top

- Coolant

- Corona

- Cowl

- Cruise Control

- Cruising

- CT6

- CV Boots

- CV JOINTS

- D6230

- Dash Trim

- Decal Removal

- Decals

- Decoration

- Dehumidifier

- Delco Moraine

- Der Standard

- detailing

- Deville

- Diagnosis Chart

- Diagram

- Dial

- Digital Rotary Drum Clock

- Diner

- Disc Brakes

- Distributor

- Diverter Valve

- Door Jamb Switch

- Door Rubber Conduit

- Dornbirn

- Dot3

- Drive Shaft

- Driving tour

- Drum brakes

- Dry Ice Blasting

- Dry Ice Cleaning

- DVD

- Eastwood

- Eldorado

- Electric Choke Thermostat

- Electrical schematic

- Elvis

- Engine Bay

- Ep

- Epoxy floor

- Europe

- Evaporator

- Exide

- Factory Markings

- Fender Skirt

- Floor

- Flushing

- Flyer

- Foam

- For Sale

- Front AXLE

- Front brakes

- Front bumper filler

- Front Floor

- Front wheel bearing

- Fuel Filter

- Fuel Pump

- Fuel Sending Unit

- Fusible Link

- Garage

- Garage Cabinets

- Gasket

- GE

- Gear indicator

- General Time

- Glove box light

- Grand European

- H4

- Haus of Hot Rod

- Headlight Actuator

- Headlight doors

- Headlights

- Heater Core

- Heater Hose

- Heater Valve

- High Idle

- History

- Holley

- Honest John

- Hood

- Hood Emblem

- Hood Ornament

- Hose Clamp

- Hot Choke

- Hot Water Valve

- HotRod

- How to

- Hödlmayr

- Ignition Diagram

- Illuminated Entry

- John D‘Agostino

- John Foust

- Klassikwelt Bodensee

- Kremsmünster

- LaSalle

- Leather seats

- Light Switch

- Limited

- Lincoln

- Lincoln Mark III Repair Tip

- Low Mileage

- Magazine

- Marilyn Monroe

- Mark III

- Master Cylinder

- Master Switch

- Master Vacuum Switch

- Media Blasting

- Meeting

- Meguiras

- MK II

- Mobile

- Model

- Moldings

- Mom

- Mopar Nationals

- Mostkost Kustom

- Movie

- Munich

- Neon

- NOS

- Oberösterreicher des Tages

- oilchange

- ORF

- Overspray

- Pacer

- Paint

- Paint correction

- Paintjob

- Part Number

- Parts

- Patch Panel

- Perfect Circle

- Permabag

- Persian Lime

- Photo shooting

- Photoshooting

- Pictures

- PinUp

- POA Valve

- Power Antenna

- Power Servo

- Power Vent Windows

- Power Window

- Printed Circuit Board

- Programmer

- Pulley

- Quadrajet

- Quarter Panel

- Quartz Conversion

- R134

- Radiator

- Radio

- Rattle

- Rear brakes

- Rebuild

- Recalibrate

- RediRad

- Reed Switch

- Relais

- Relaunch

- Removing Overspray

- Repaint

- Repair

- Restoration

- RIP

- Roadhouse

- Roadmaster

- Rochester

- Rocker Arm Cover

- Rocker Panel Extension Clips

- Rostio

- Rotary Valve

- Rotterdam

- Rupes

- Rust removal

- Rust removal gel

- Sabre Wheels

- Sand Blasting

- Sandblasting

- Screed

- Season Greetings

- Seasons Greetings

- Seat Back Locks

- Seat Padding

- Seat Transmission

- See through ornament

- Self adjusters

- Self Starter

- Sepp's Garage

- Seville

- Sheetmetal

- Shocks

- shop manual

- short

- Sign

- Solenoid

- Spark Plug Wire Routing

- Speakers

- Special Award

- Speed Bleeder Screws

- Splash Guard

- Starter Diagram

- Starter Motor

- Steering Column

- Storage

- suction throttling valve

- sunroof

- suspension

- Swirl Mark removal

- Switzerland

- T3

- Taillight Cover

- Texan´s Choice Award

- Thermostat

- Tilt and Telescope

- Time capsule

- Tomsclub

- Torque Specifications

- Tower Hose Clamp

- Towtruck

- Trailer

- Transducer

- Transmission

- transmission control selector

- transmission control selector indicator light

- transmission shift indicator

- Treadle Vac

- Treffen

- Tri-Band

- Troubleshooting

- Trunk Cardboard Kit

- Trunk lid

- Trunk lining

- Trunk to bumper cover

- Turn Signal Switch

- TV

- Typisierung

- Ultimate Garage

- Underbody

- Undercarriage

- Undercoating

- Undercoating Removal

- Vacuum Booster

- Vacuum diagram

- Vacuum hoses

- Vacuum Master Switch

- Vacuum Schematic

- Vacuum Valve

- Valve Cover

- Various

- Vent Window Switch

- Vibration

- Vibrator

- Vicodec roof

- Video

- Vinegar

- Vinyl Roof

- Visitor

- Washer Fluid Float

- Washer Fluid Low Level Indicator

- Water Pump

- Wax

- Weatherstripping

- Website News

- Westclox

- Wheel Bearings

- Wheel Housing

- Wiesbaden

- Windlace

- Winter

- Wiring

- Wiring Diagram

- Wonderbar

- Workbench

- Zurzach

GERALD´S CADILLACS - NEWS

GERALD´S CADILLACS - NEWS