LINCOLN MARK III CARBURETOR REBUILD

CLICK BELOW TO READ MORE

READ MORE...

A6 AC COMPRESSOR REPAIR - BAD BEARING ON THE 1974

Due to all the other projects I never managed to get the AC back in fully working order until now.

Unfortunately the rebuilt AC compressor came with the clutch coil terminals in the wrong position. They are available with the terminals at the correct 10 o clock position or the 2 o clock position, which is correct for other years.

If the terminals are in the wrong position you cant connect the original wires to them as they are too short. With the high shipping costs it was no option to send the incorrect compressor back.

As it turned out the cars original compressor had a bad bearing and that was the reason why it was disconnected.

My friends Lucky and Steve were here to help me with the compressor project and so I took both of my compressors to Lucky´s workshop, as he has all the necessary tools and experience with these compressors from his own cars.

Originally I just wanted to turn the clutch coil on the rebuilt compressor into the correct position, but then we decided to rebuild the original compressor instead, because it still has the original decal, which is not available as a correct reproduction. All the available compressor reproduction decals are TOTALLY incorrect for the 1974 Cadillacs. The 1974 reproduction decals all show the wrong amount of refrigerant! They are also different in many other details. The closest match of reproductions for 1974 are the ones from 1972 Cadillacs…

We still disassembled the rebuilt compressor to "borrow" its pulley bearing to replace the bad one on the original compressor.

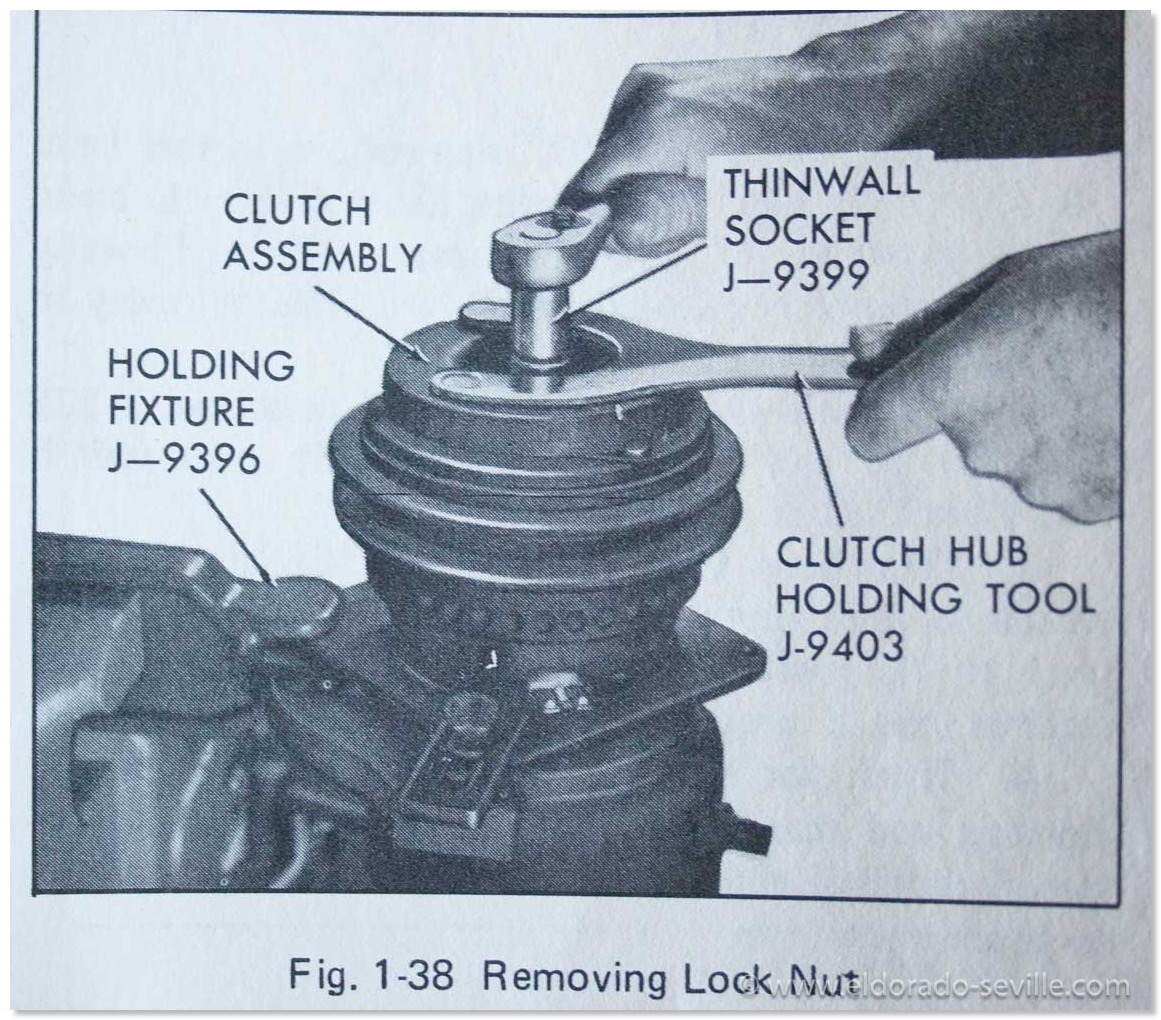

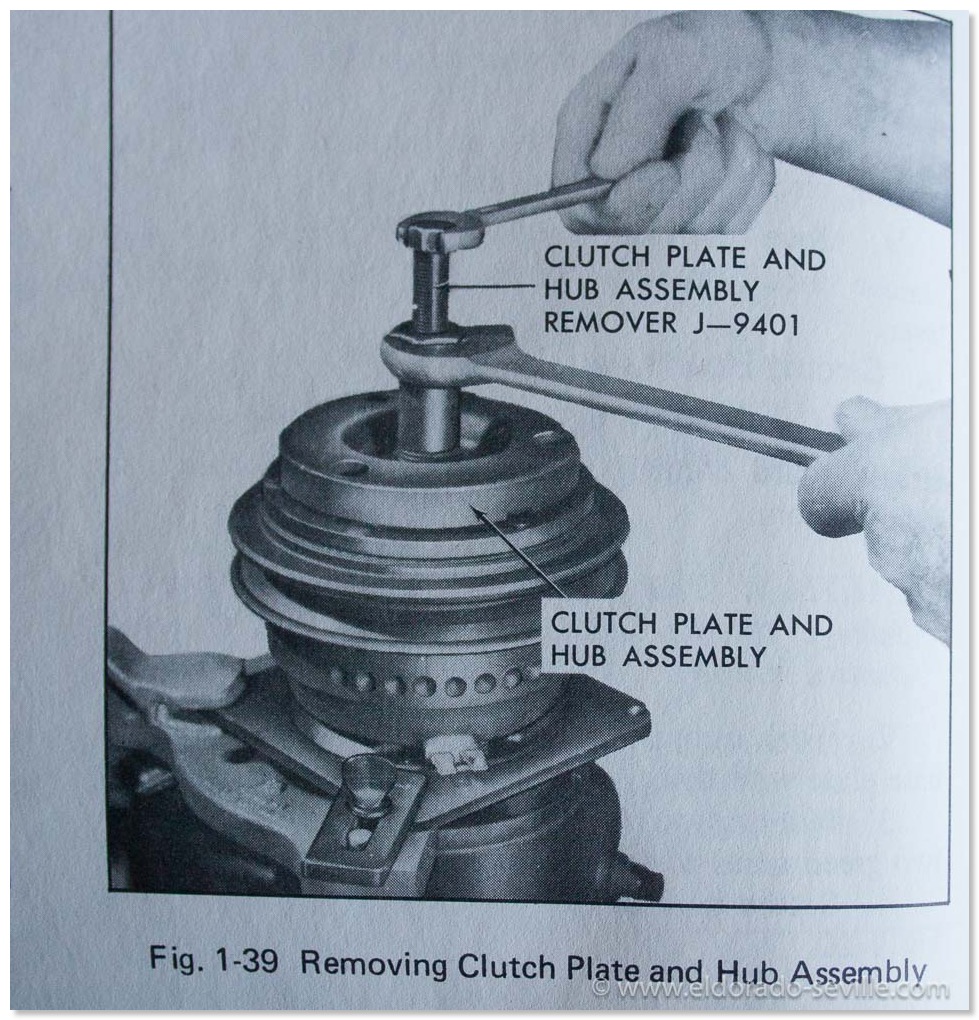

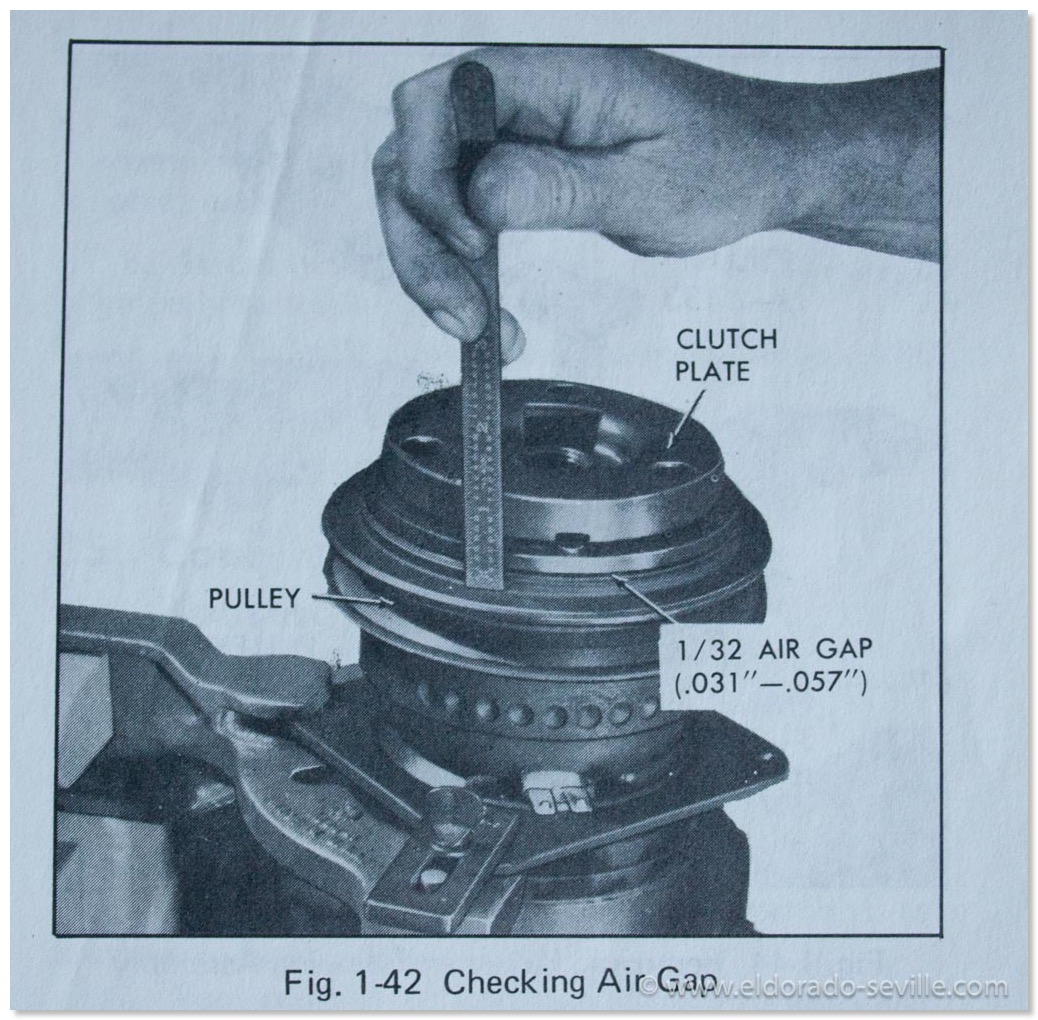

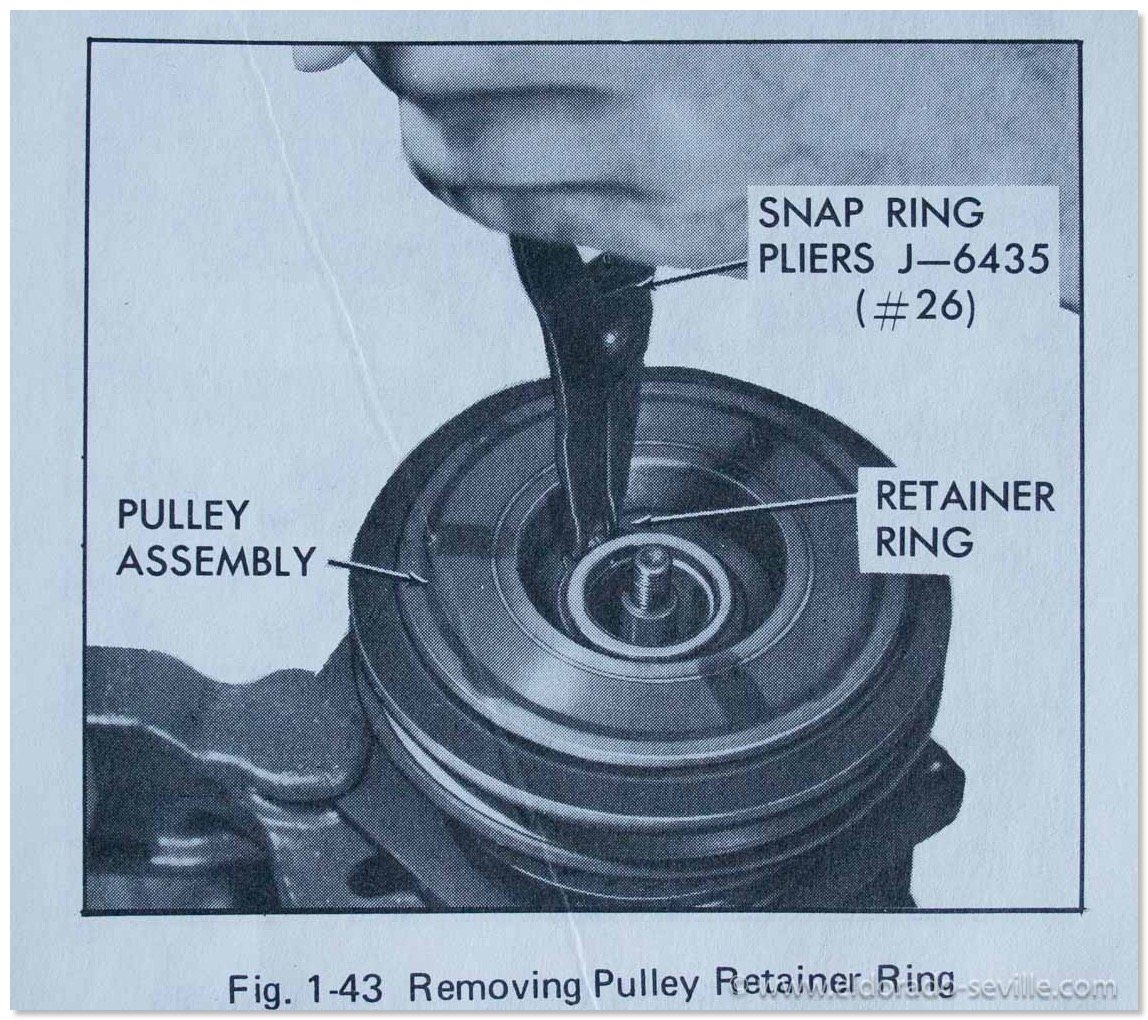

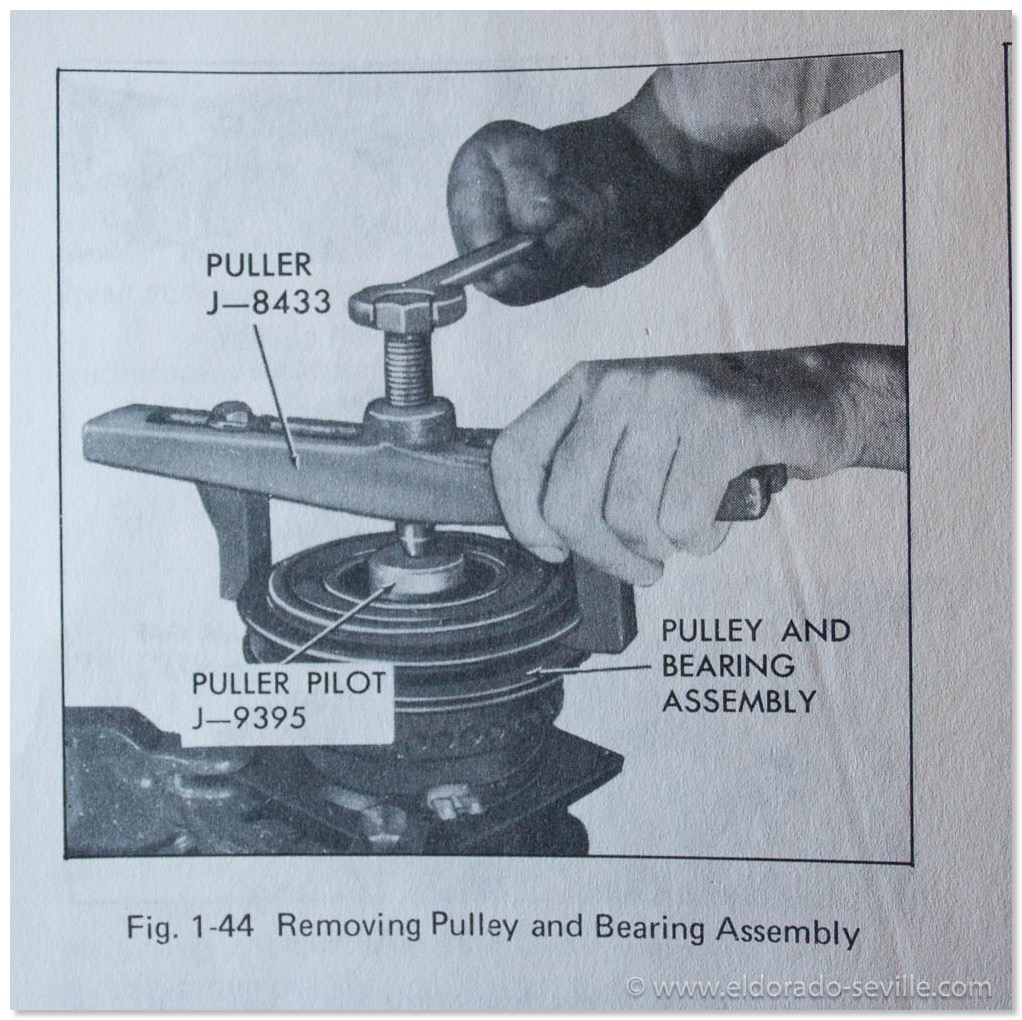

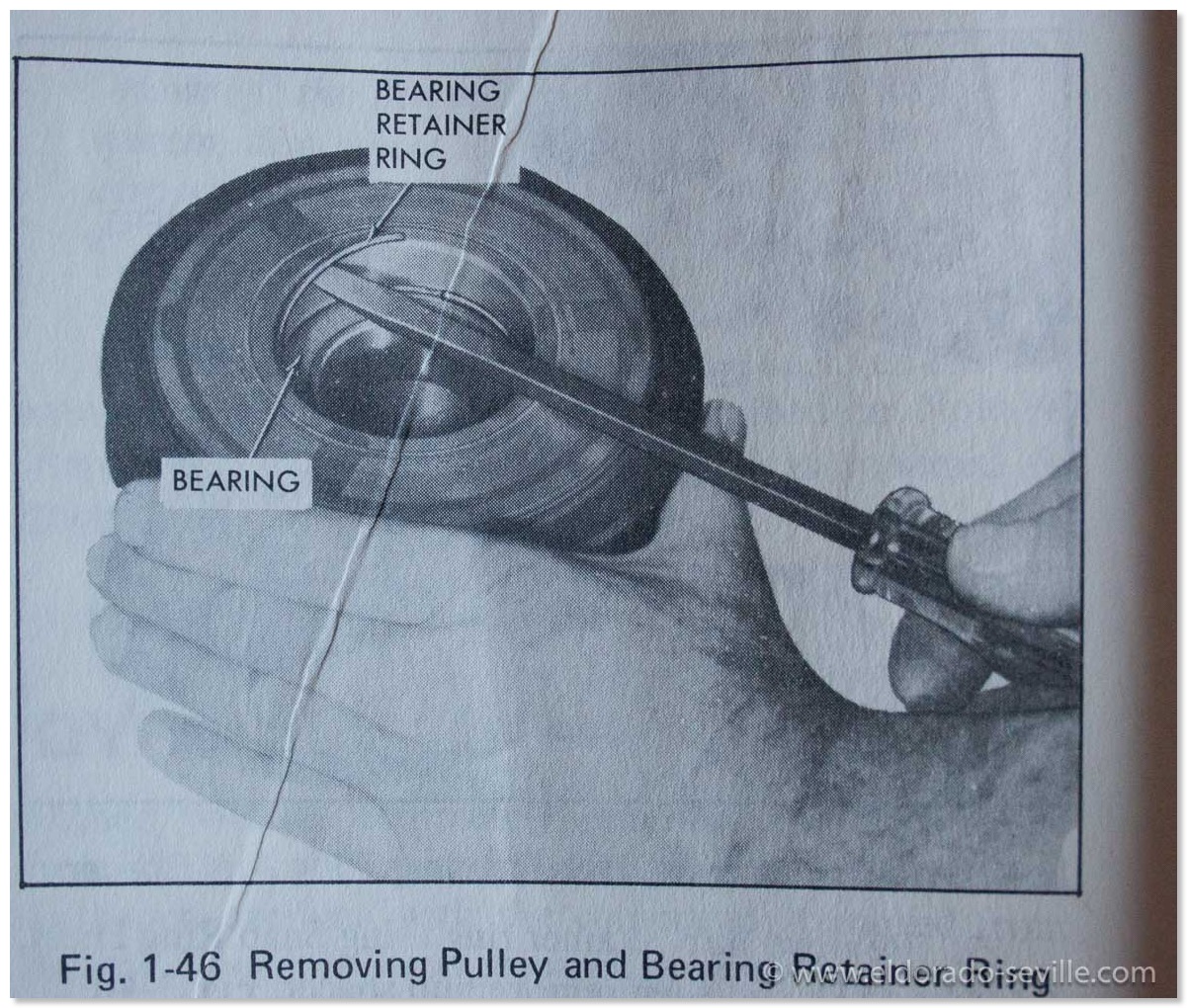

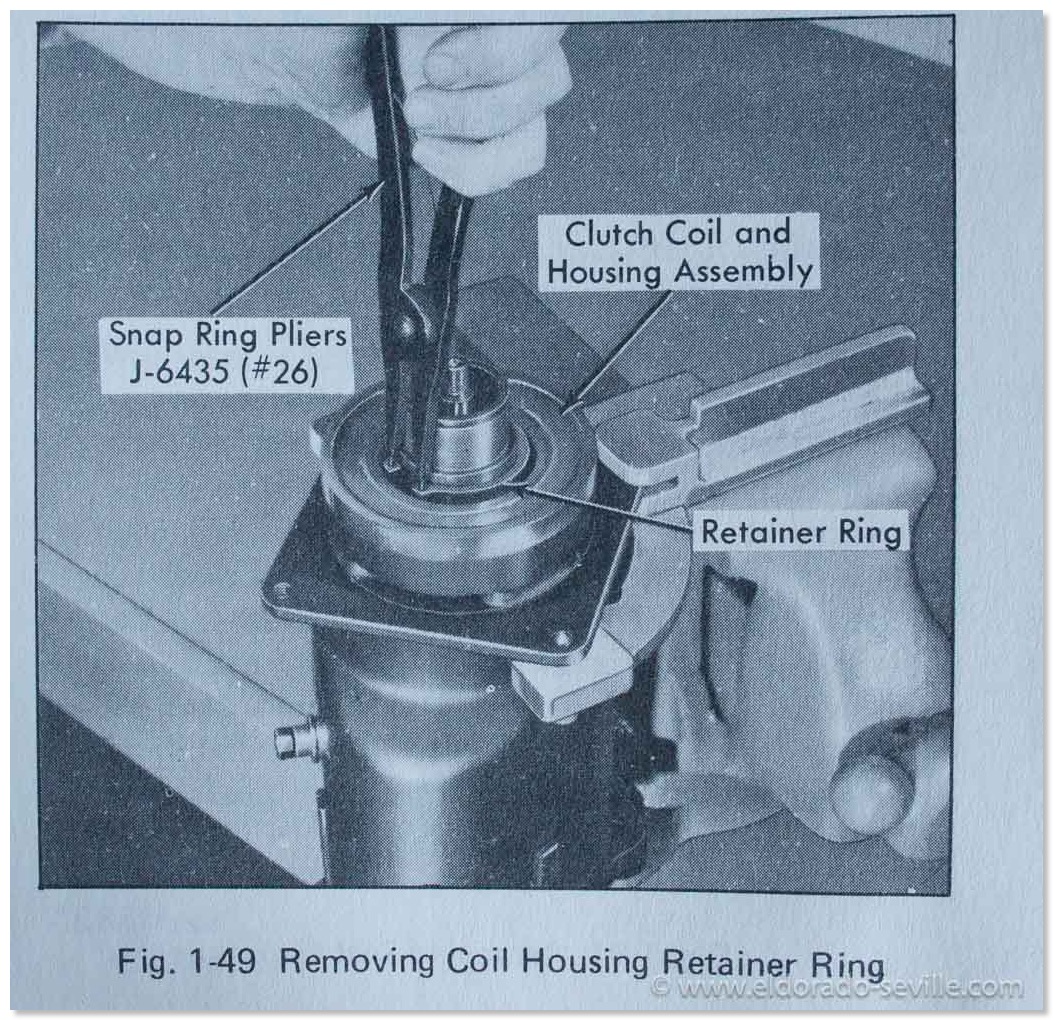

The procedure to be able to replace the bearing and to turn the clutch coil is not too difficult - but you need some special tools. Without those you cant do it. You´ll need a basic clutch puller / installer set for this job and some long nose snap ring pliers to get the retaining rings out.

First remove the shaft nut and the snap ring ( the rebuilt compressors always seem to come without this snap ring) and then pull the clutch with the special puller. Pull off the pulley and take the bearing out and replace it with a new one.

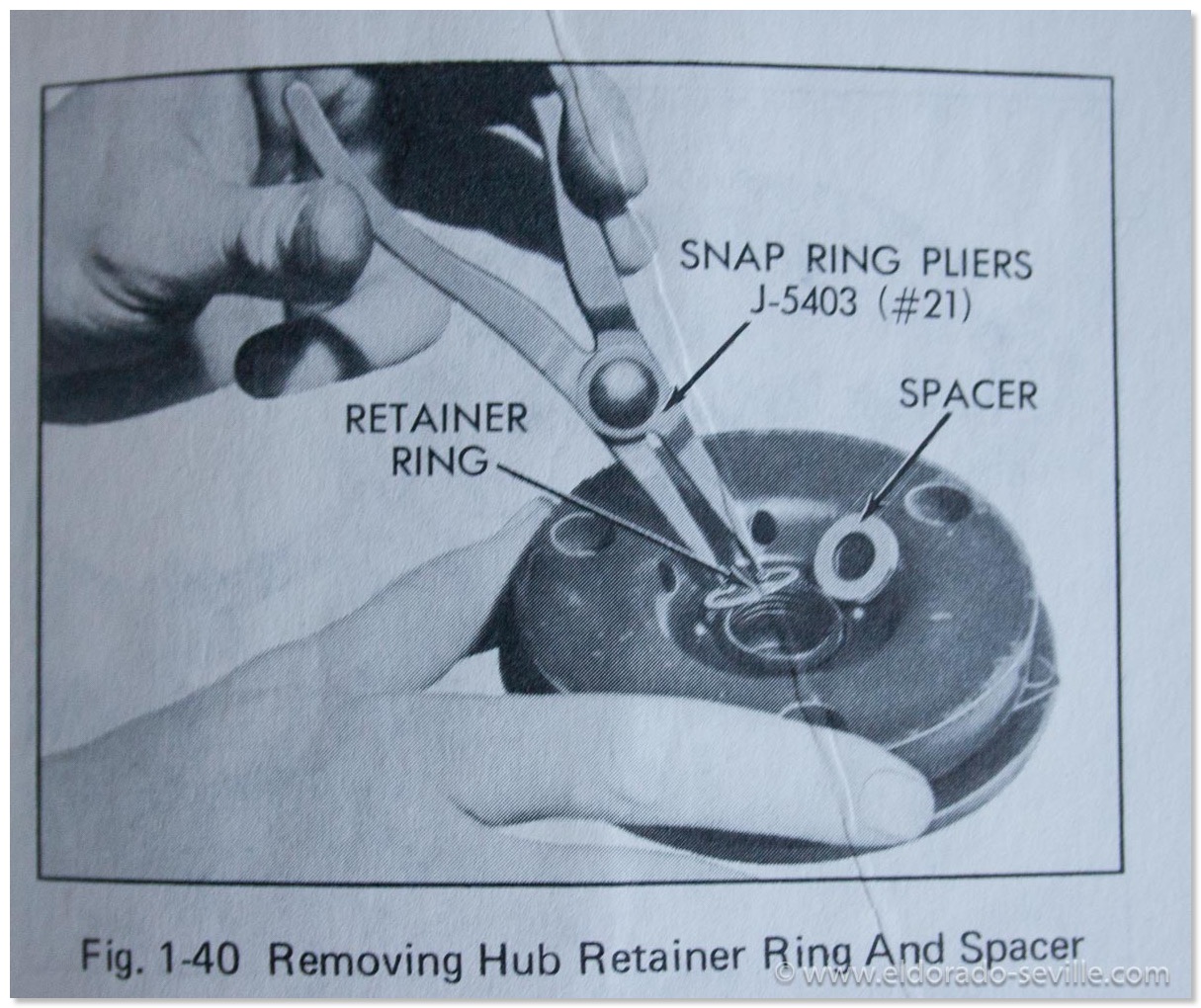

To be able to turn the clutch coil you´ll have to remove another snap ring. This snap ring was the biggest challenge for us. The shop manual lists a special tool for this which we of course did not have… It could be done with a very long nose plier as well, but we did not have these either. So it took us quite a long time to get it out with screwdrivers and self made hooks… You can then simply turn the coil into the correct position.

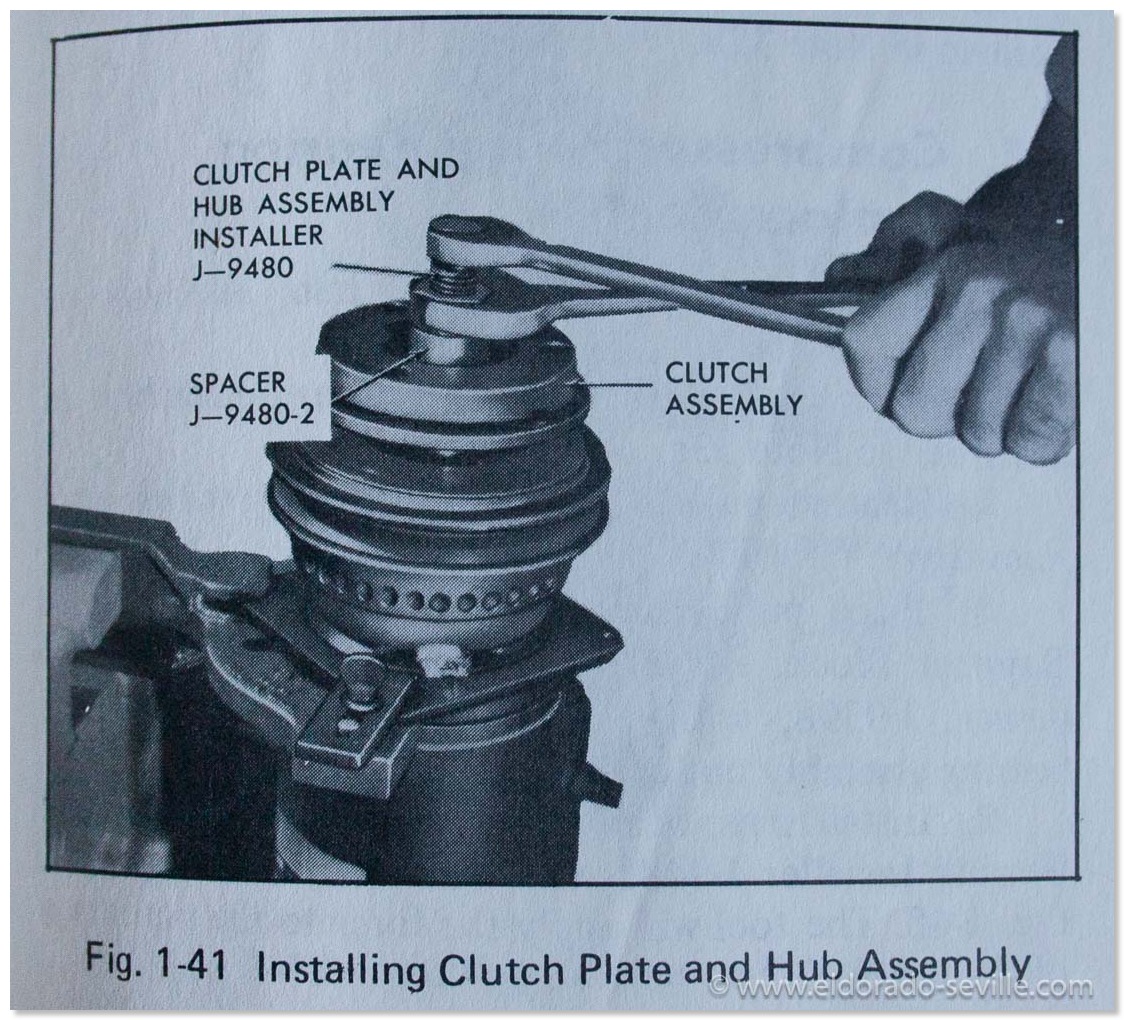

Putting it back together is pretty straightforward as well, but again you need a special installer tool to get the clutch back on and to adjust it properly.

I will now have to buy a new bearing so that I can put the rebuilt compressor back together and have it as a spare.

I have attached some pics from the shop manual which show how to remove the various parts of the compressor to remove the pulley and the clutch coil.

As always you can find ALL the pictures in my restoration gallery!

You need some special tools to disassemble the A6 AC compressor.

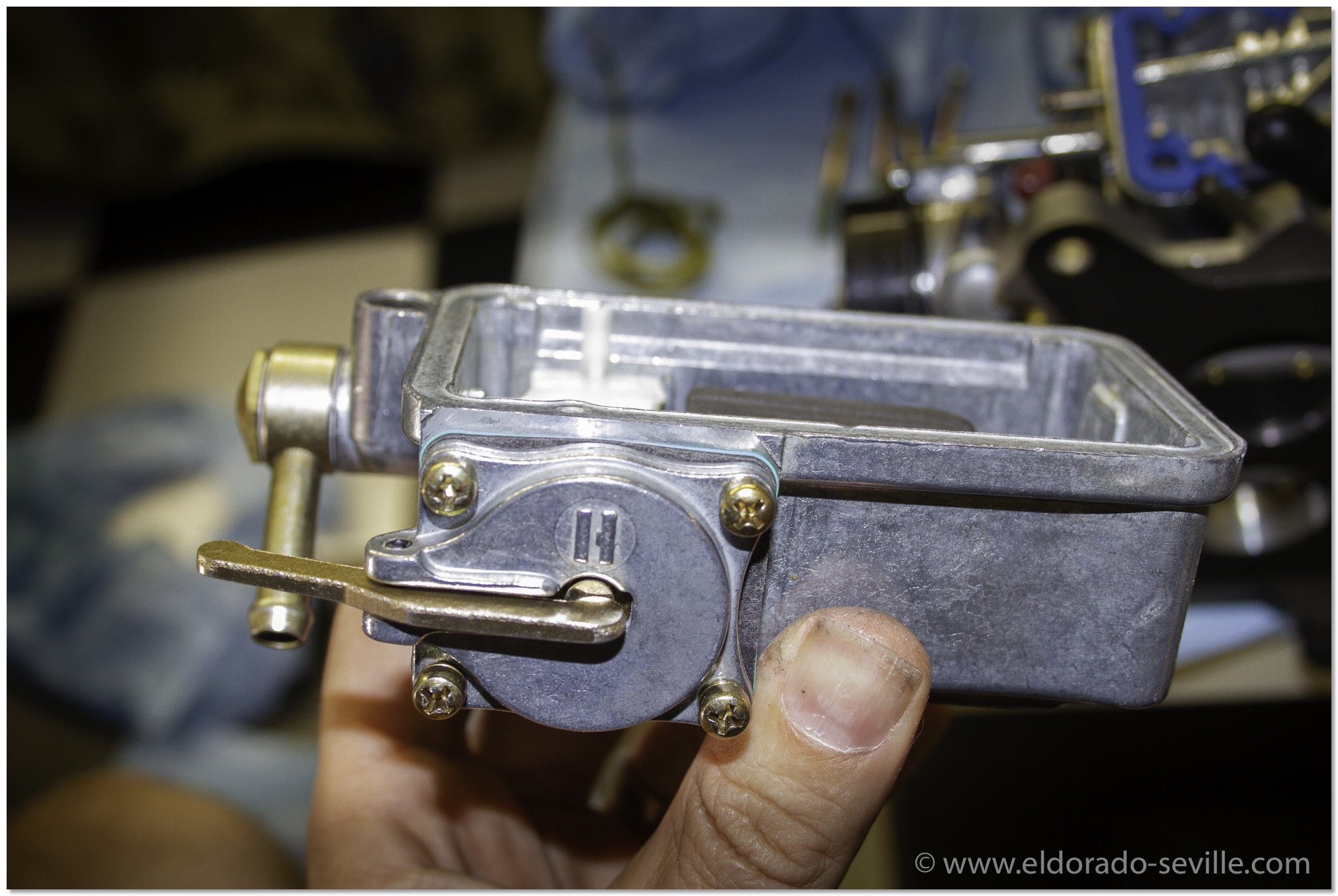

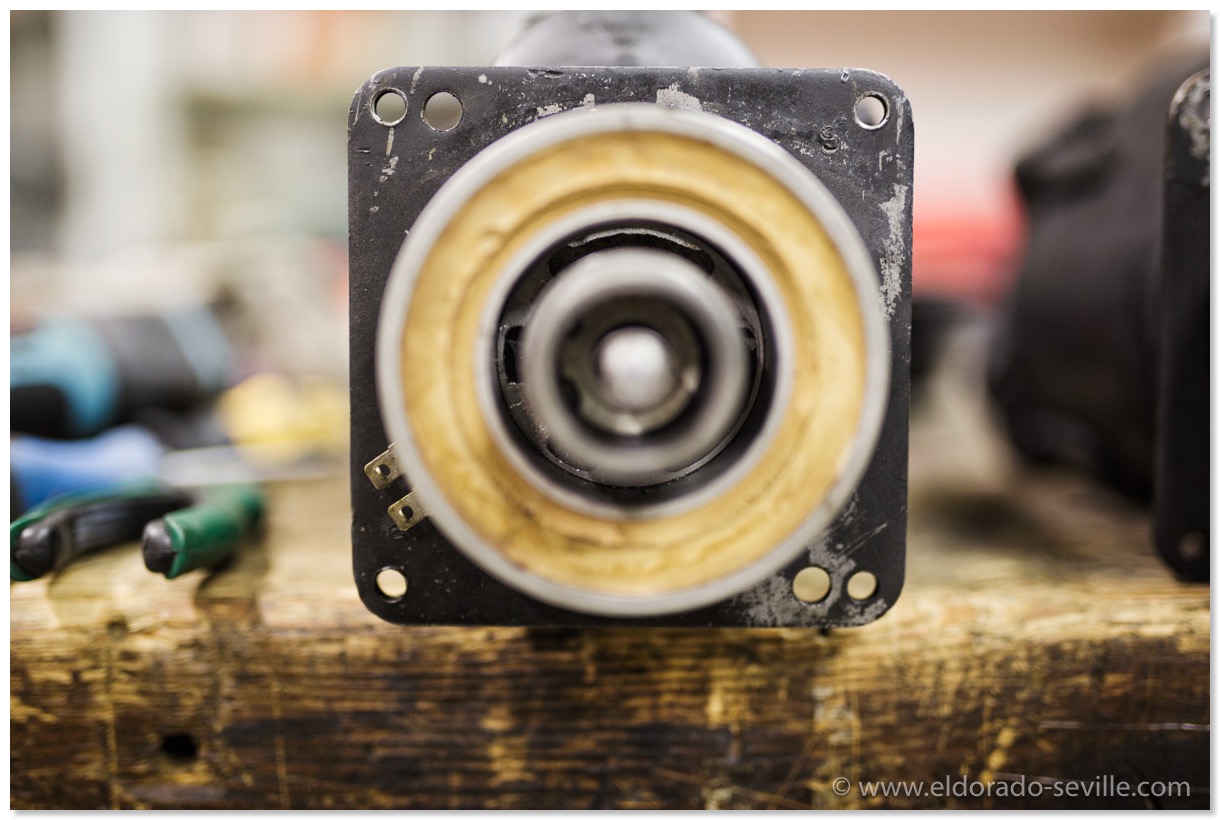

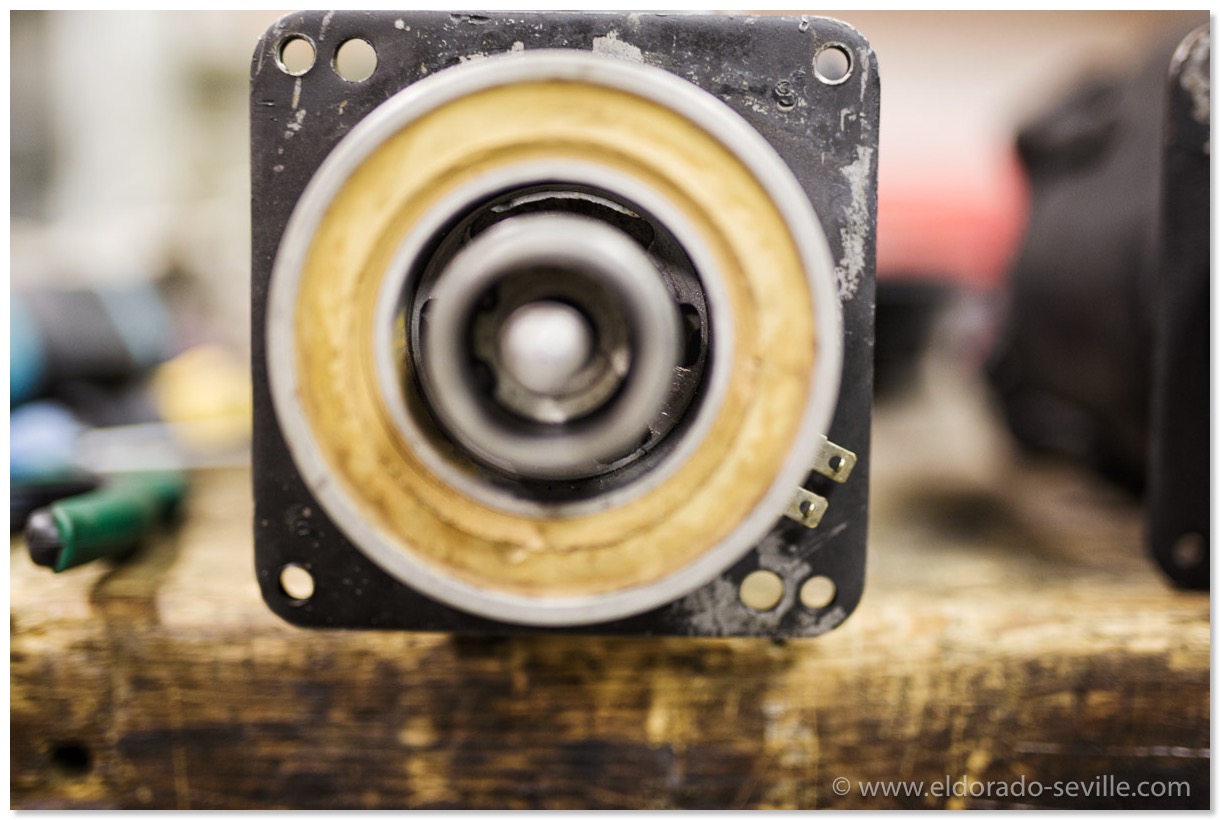

On the 74´s original AC compressor clutch the bearing was bad.

The compressor clutch removed. You can see the bad bearing inside which is normally sealed. Some balls were already missing.

The clutch with some remains of the bearings.

The clutch and pulley removed on the original compressor.

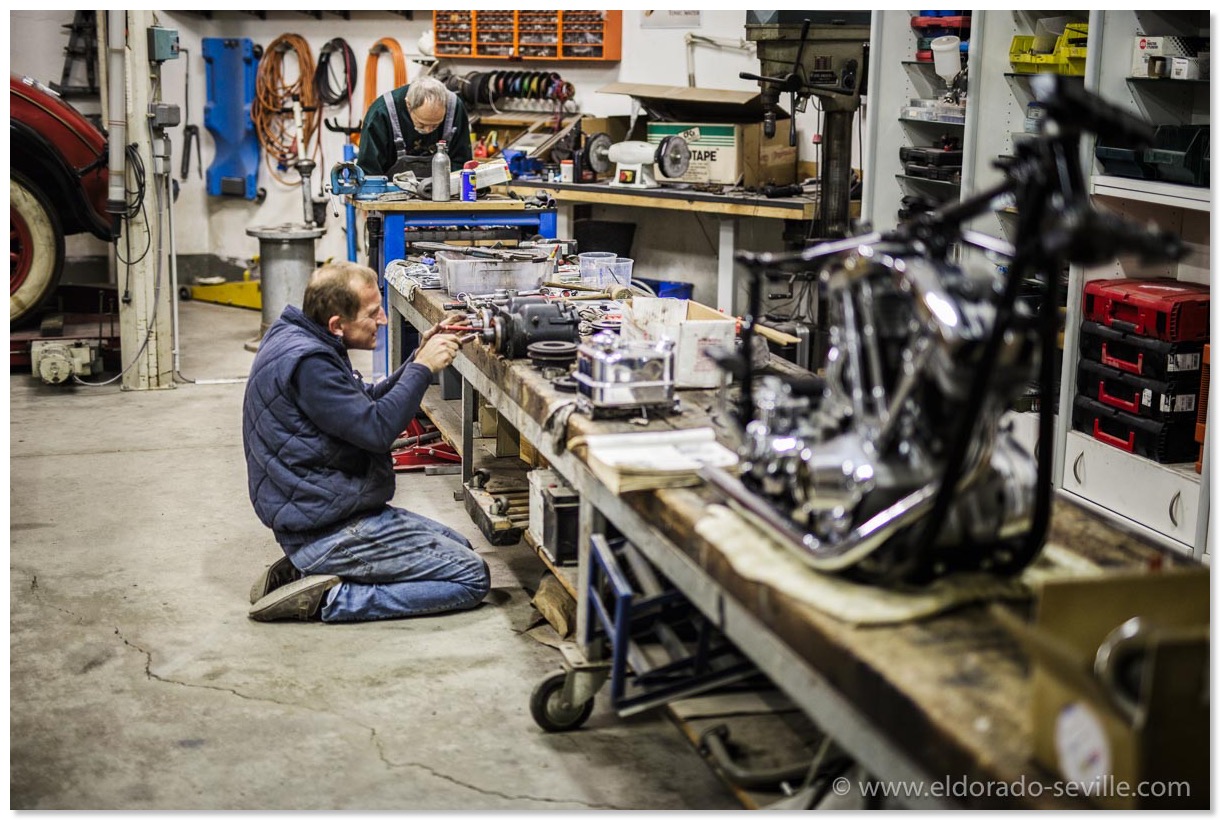

My friends Steve and Lucky at work. We also replaced all the O - rings.

Removing the pulley

Removing the pulley from the rebuilt compressor.

There is this one snap ring we just did not have the right tool for. The shop manual lists a special plier for this. After a lot of fiddling we got it out eventually…

The magnetic coils on the rebuilt and the original compressor

Lucky in action

Once the snap ring is out you can turn the coils terminals to the 11o´clock position or the 1 o clock position. On the 74 it has to be at the 10 o clock position, otherwise the connecting wires are too short.

Getting this snap ring out was the hardest part on this job, due to not having the right tool for it.

The terminal at the incorrect position at the rebuilt compressor.

We turned the terminal to the correct position.

We sandblasted the pulley while it was out of the car so that I can repaint it now. Note the original decal! All the available reproduction decals are totally incorrect for the 1974 Cadillacs. The reproduction decals all show the wrong amount of refrigerant! They are also different in many other details. The closest match of reproduction decals for 1974 are the ones from 1972 Cadillacs…

REPAIRING THE 1967 CADILLAC AC CONTROL HEAD

This time the 67 Eldorado had a new problem which I had to fix.

It suddenly only blew hot air out of the AC outlets. It did not change modes at all. That was a sign of a weak vacuum signal…

I started to inspect all the AC related vacuum lines of the car which checked out fine. Next I did the test I´m describing here in an older posting, as I suspected that the power servo had a problem.

I soon found out that still not enough vacuum was supplied through the transducer.

That meant that either the transducer could be faulty, the temperature sensor could be defective, or the dash control head would not work properly. I took out the temperature sensor of my 67 Deville to test it in the Eldorado but it did not change anything.

I then removed the control head and tested it with a spare one I once bought cheaply on ebay. It did miss some connectors and switches, it had some blemishes on the chrome and did not look good enough to install it into any of my cars. When I put it into the Eldorado anyway the AC suddenly worked perfectly again.

So I removed all the electrical parts from this working unit and transferred it to the perfectly looking but defective control head. After I had swapped all the usable parts I put the unit back into the car and I now have a perfectly working unit once again.

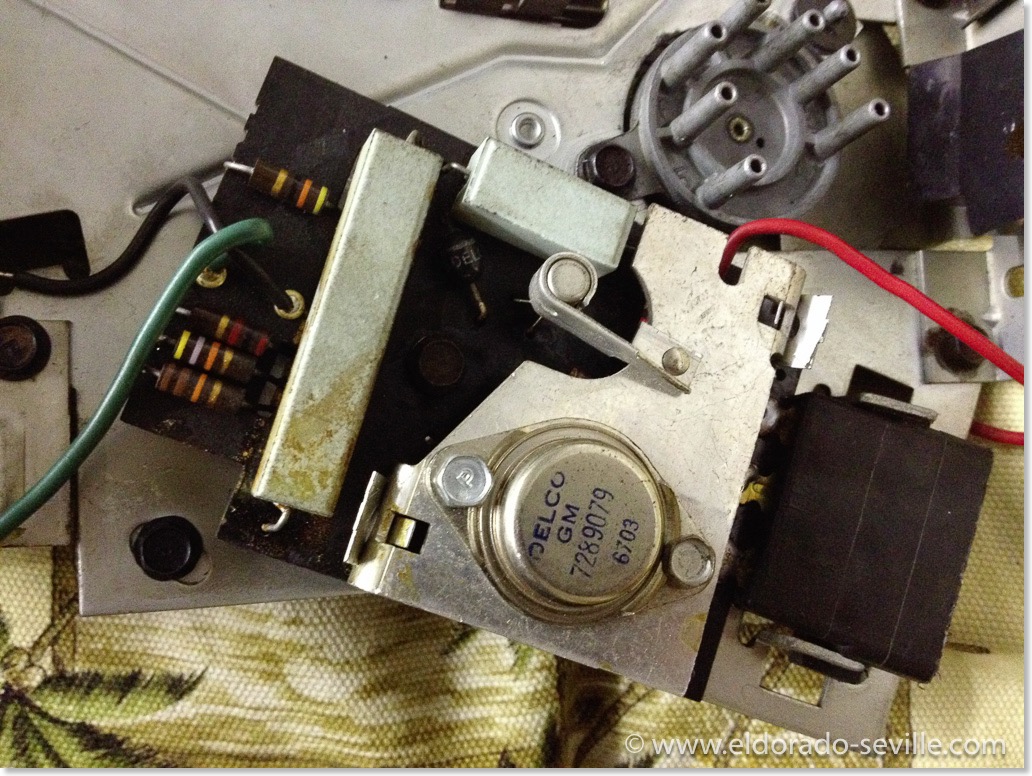

It looks like that there was a problem in the amplifier part which translates the signal coming from the rheostat into a current going to the transducer which regulates the vacuum going to the control head and the power servo.

Lets see what issue comes up next spring…

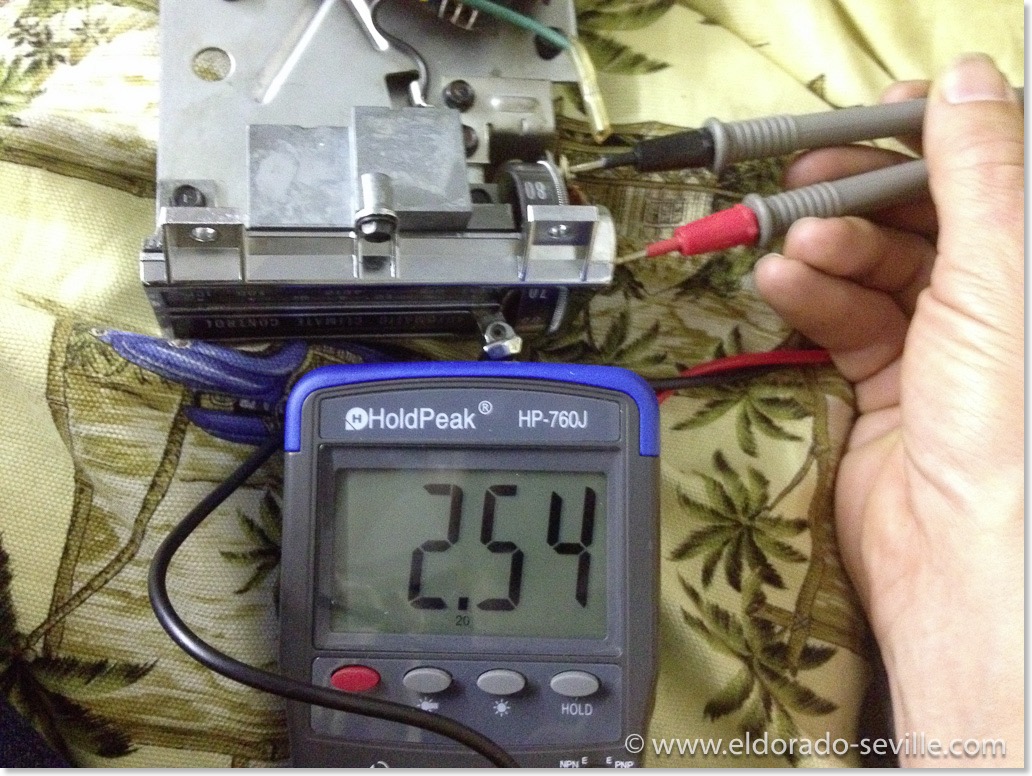

The Rheostat when set to the lowest temperature setting shows around 2,5 Ω You can check if it is working with an Ohmmeter.

At the highest temperature setting the resistance is getting lower.

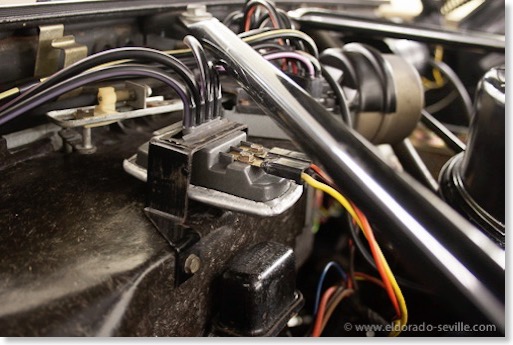

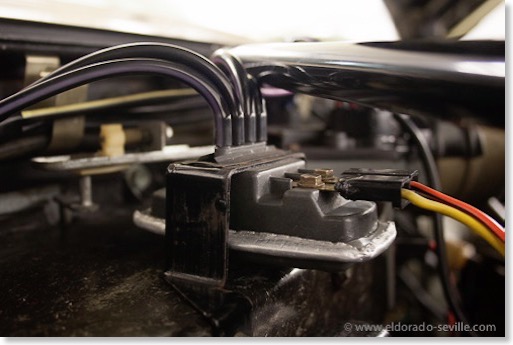

The Amplifier part of the control head is on the underside. Something in here must have gone bad on my control head. I will try to find out what went bad and repair it to have a spare part.

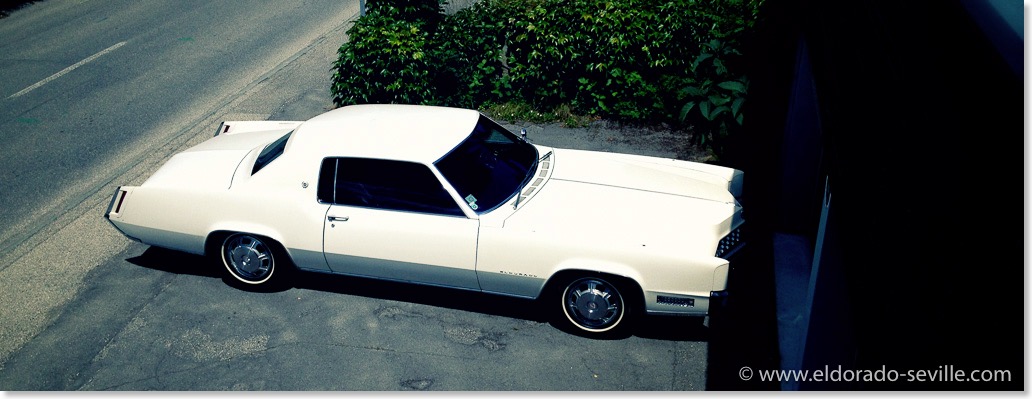

The 67 Eldorado is back on the road for the 2015 season.

REPAIRING THE 6 WAY POWER SEAT OF THE 1958 ELDORADO SEVILLE

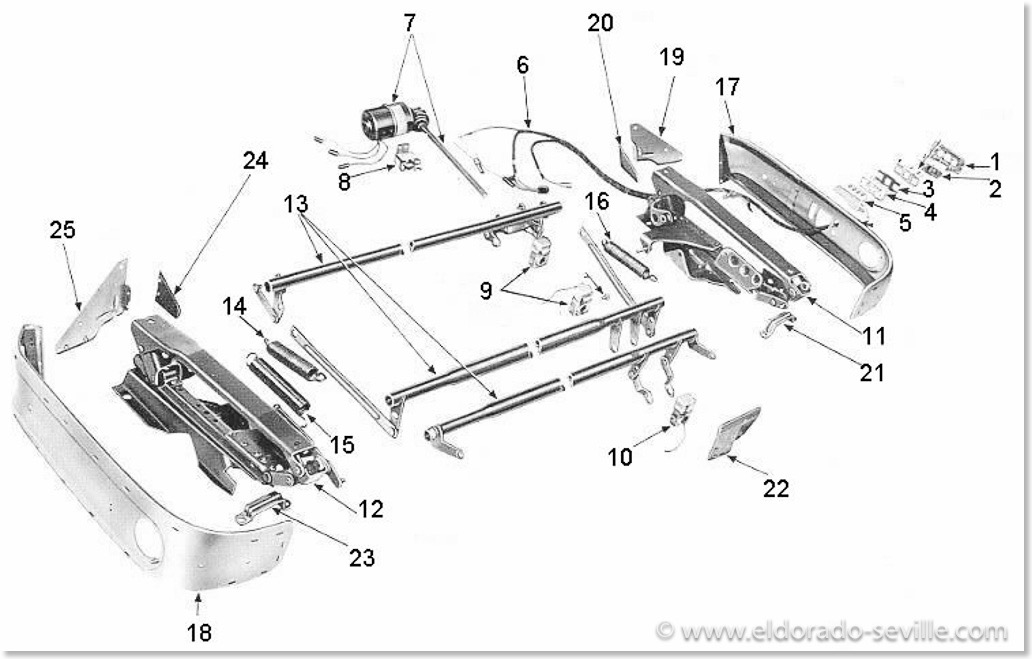

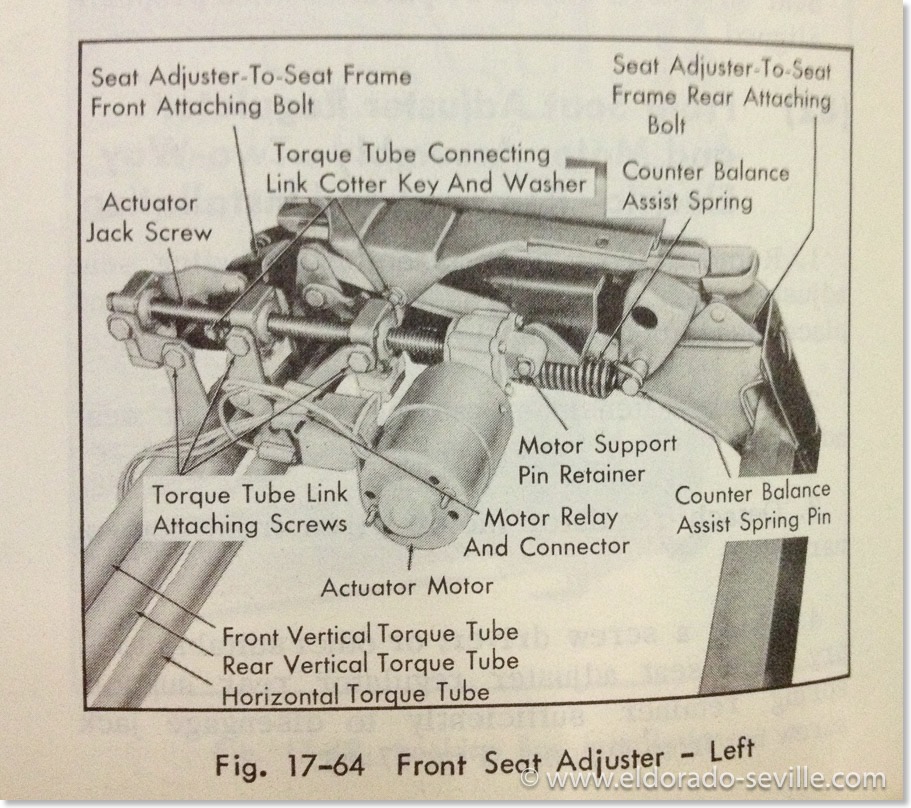

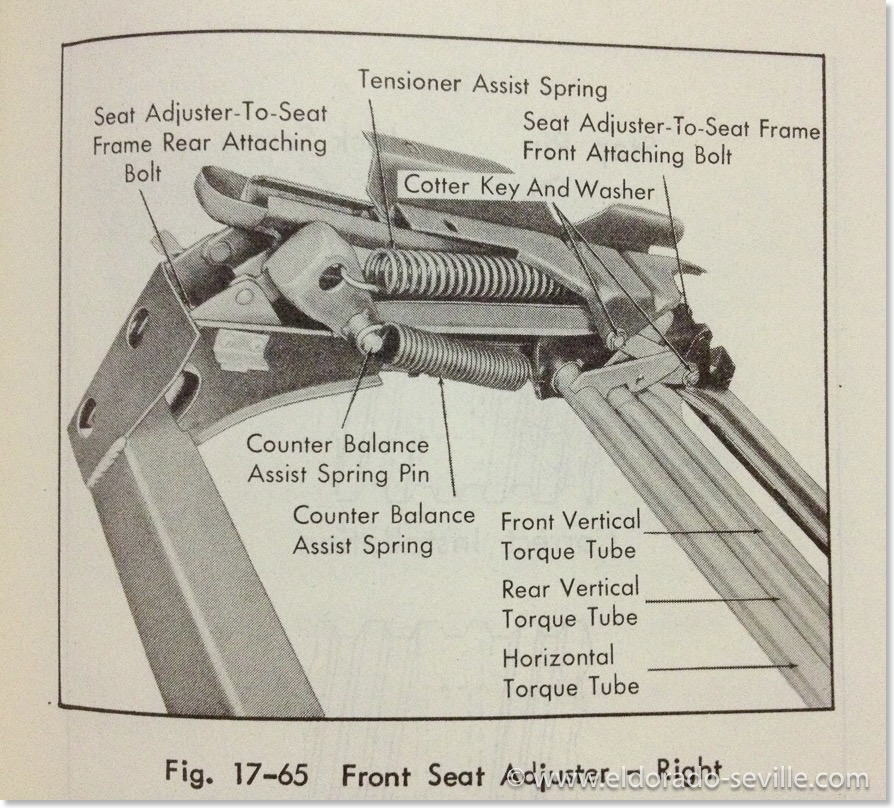

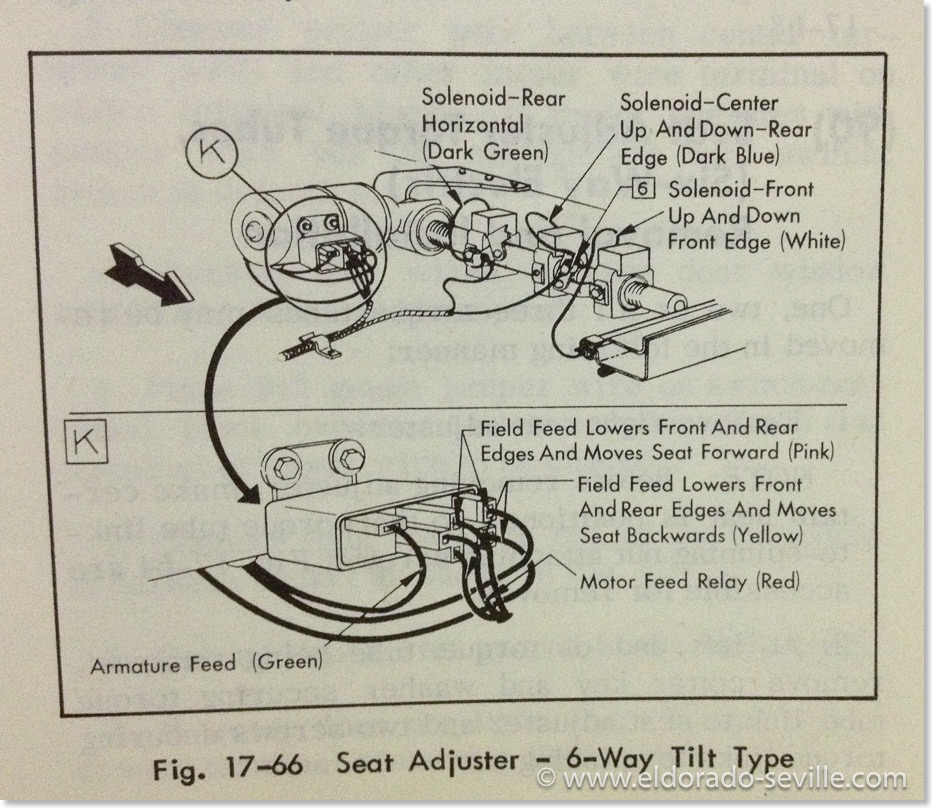

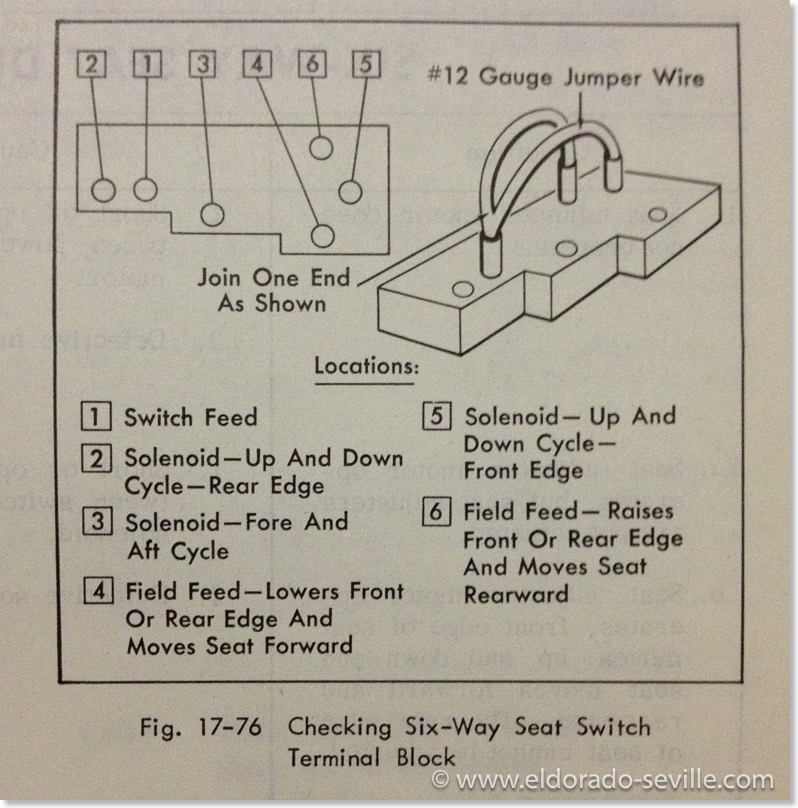

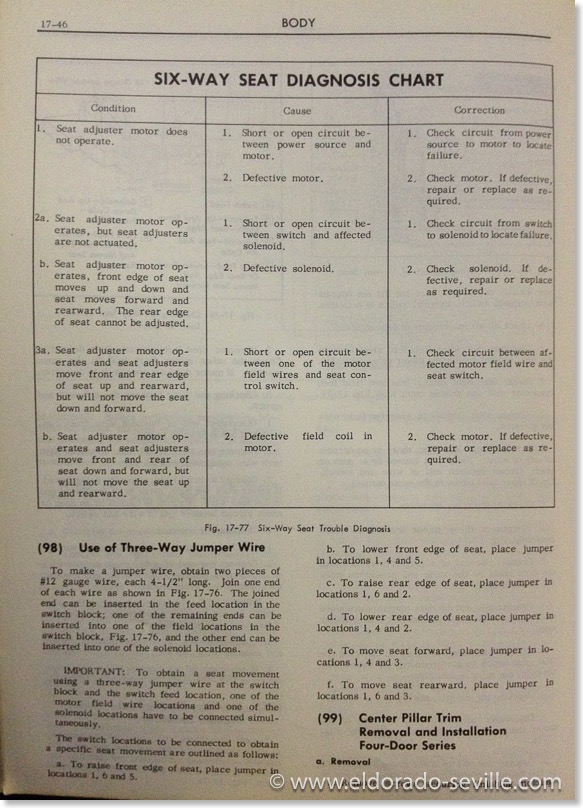

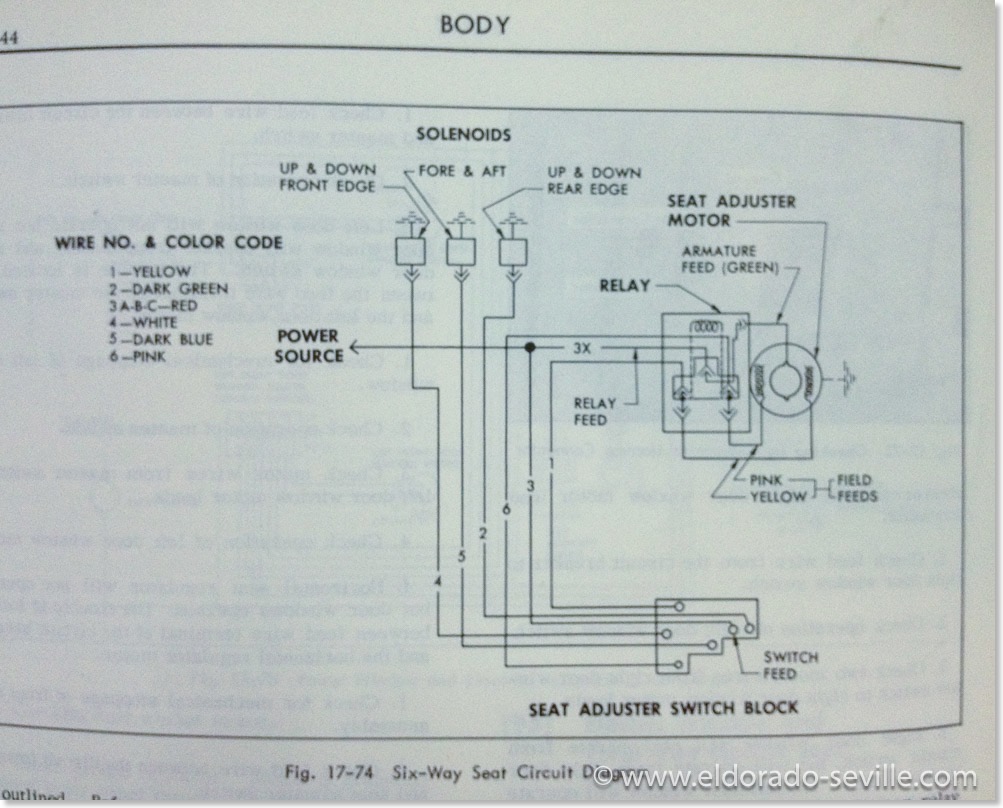

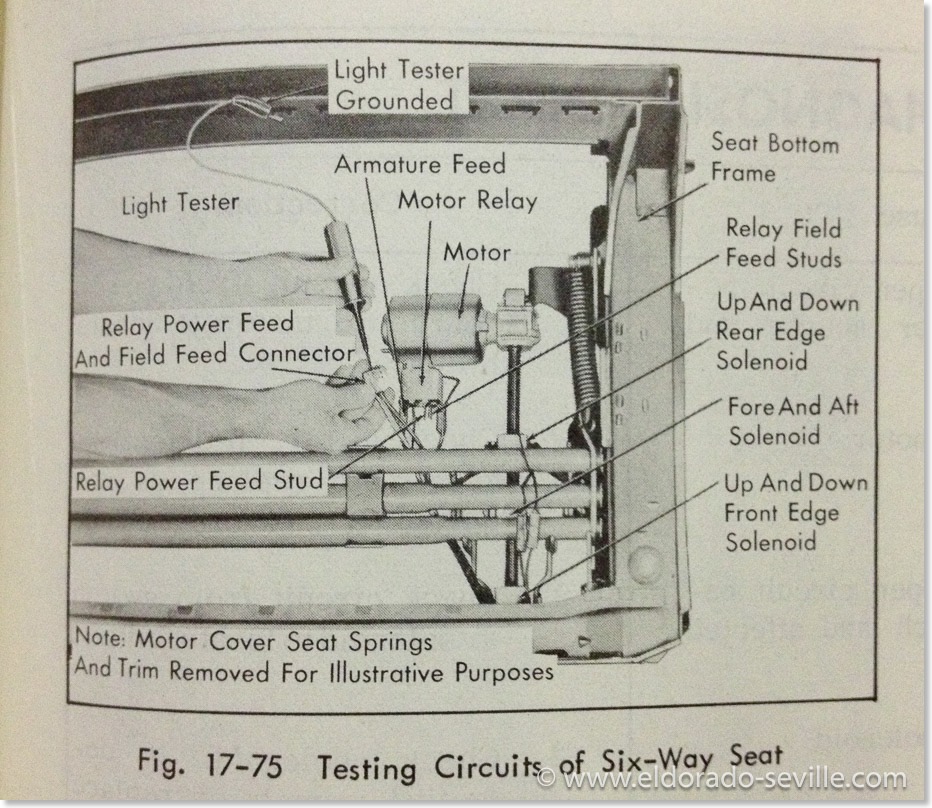

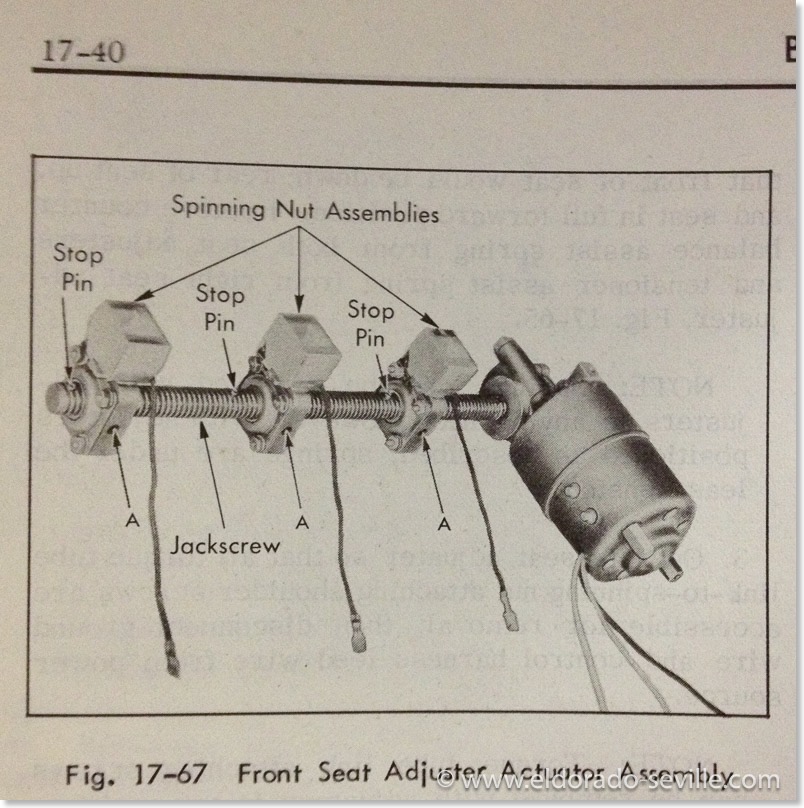

First I suspected that the switch has a problem - so I took it apart. With a test light you can easily test its function. With a three way jumper wire you can simulate the switch as well at the switch connector. You can see the picture below from the shop manual and its described which terminals you have to connect together to get the desired movement. The shop manual is extremely helpful in diagnosing any seat related problem. Check it out below!

Everything was fine at the switch. So I checked the wires going to the solenoids. There is a plug underneath the switch and I checked the wires from there. Everything was ok there as well.

For some reason the mechanism still did not engage. The front actuator was repaired by the previous owner once, as there were some screws in there which originally were not used. I tightened them and suddenly it worked again when I almost wanted to give up and wanted to try to find a good used one from one of the Cadillac parts places.

I hope it will work now for a long time. The seat is fully adjustable again.

Below are some pictures from the shop manual which should be very helpful if you have power seat problems as well.

Six-way power seat diagram.

Thats the front actuator and solenoid which had a problem on my car. The mechanism did not engage for some unknown reason. Probably a bad internal contact or the mechanism was stuck somehow.

This 3 way jumper wire is very helpful to test the various functions and to rule out any problem with the switch.

The procedure to test all the functions of the seat.

The 6 way power seat wiring diagram.

How to test the circuits.

Front Seat Adjuster Actuator Assembly (1957 and 1958)

REPAIRING THE AIRCONDITION OF THE 1966 COUPE DEVILLE

So I started to search for the cause of the problem.

Everything seemed to be fine on the vacuum side. When the lever on the control panel was moved all the vacuum actuated doors operated and the master vacuum switch also seemed to work.

After some searching I found out that no current was flowing through the master vacuum switch on the firewall.

So the switch was taken apart.

If you do this you have to be very careful not to damage the membrane.

The contacts inside the switch were oxidized and so no more current could flow through.

The contacts were also adjusted so that the switch could engage properly when vacuum was applied.

When everything was put back together the whole system once again worked as it should.

It works absolutely perfect now.

*UPDATE 2022* - Check out this article and video as well!

Unfortunately I forgot to take pictures of the switch rebuild but here is a video on youtube where a gentleman explains how this switch works…

A video that explains how this switch works

The original AC system of the 1966 Coupe deVille is now working perfectly again.

Thats the master vacuum switch which was defective.

The rebuilt master vacuum switch.

Repairing the Treadle Vac Master Cylinder and Brake Booster of my 58 Eldorado

Now as I wanted to drive it out of the garage, I found a puddle of brake fluid under the car.

So I went on to search where it was coming from.

I suspected a leaking wheel cylinder, but could not find any traces of fluid coming from the wheels. After some more searching, I eventually found out that fluid was dripping out under the brake booster along the push rod. When I checked the fluid level it was only half full.

So I knew that the Treadle Vac would need a full rebuild…

I ordered a rebuild kit at Cadillac Parts LTD. They offer a kit to rebuild everything from the booster to the master cylinder. As I found out, the gasket for the reservoir did not fit from their set and some other correct smaller rubber parts are also not included in the set. So remove everything carefully from your unit as you might have to reuse some parts for your rebuild. I contacted them about the wrong parts and they immediately sent me the correct parts by mail. Great customer services - I would order from them anytime again!

As I had never done a full rebuild I asked my Cadillac friend Lucky for help - knowing that he can repair almost everything, and that he had done this job during the full restoration of his awesome 58 Biarritz before.

He was so kind to offer his assistance and invited me to his fantastic work shop where he is restoring his cars.

So I carefully removed the whole unit from my car and visited Lucky´s workshop.

With his skills he managed to rebuild the whole unit within a couple of hours. As it turned out a bad O-ring caused fluid to leak into the booster.

Due to all the brake fluid the finish of the Bendix unit suffered a lot, and so I decided to strip everything on the outside down to bare metal to repaint it.

So I took everything apart once again to make sure to do it perfectly.

I ordered some great spray cans from Eastwood to get the perfect look to match its appearance to when it was new.

Originally the master cylinder was not painted at all - but left in bare cast metal. Of course it started to collect surface rust very quickly - even on new cars back in 1958.

The booster originally was painted in semi gloss black.

Eastwood has a product called "Brake Gray" which I used to emulate this look. It comes extremely close to bare metal, but of course the paint protects the metal from rust. This paint is also resistant against brake fluid. I first primered the master cylinder with self etching primer two times before two coats of brake gray were applied.

For the brake booster I ordered Eastwoods Chassis Black extreme primer and satin black paint - painting turned out really fine! See pictures below

To make bleeding brakes easier and a one person job I also ordered a set of speed bleeder screws. (SB3824-SS)

The unit still in the car - before removal

Removal has started

The unit out of the car - before rebuilding it.

Out of the car

In Lucky´s workshop with the rebuild kit I got from the USA

My friend Lucky at work

Lucky´s fantastic work shop

The Bendix master cylinder fully disassembled

Everything disassembled

This O-ring was leaking and caused the problem.

The new o-ring in place.

The vacuum cylinder

As you can see the paint suffered from the brake fluid - a repaint was necessary after the rebuild.

I started to wire brush the paint off - took it apart once again after this picture.

The master cylinder in primer.

After painting it with "Brake Gray" - great stuff.

The master cylinder with paint

The booster in bare metal before primer. I used Eastwood Extrem Chassis Black primer and paint.

In primer

Speed Bleeder screws

Speed Bleeder screws and bag

The new Speed Bleeder screw in place

The reassembled unit back in the car.

Repairing the Treadle Vac Master Cylinder and Brake Booster of my 58 Eldorado

Now as I wanted to drive it out of the garage, I found a puddle of brake fluid under the car.

So I went on to search where it was coming from.

I suspected a leaking wheel cylinder, but could not find any traces of fluid coming from the wheels. After some more searching, I eventually found out that fluid was dripping out under the brake booster along the push rod. When I checked the fluid level it was only half full.

So I knew that the Treadle Vac would need a full rebuild…

I ordered a rebuild kit at Cadillac Parts LTD. They offer a kit to rebuild everything from the booster to the master cylinder. As I found out, the gasket for the reservoir did not fit from their set and some other correct smaller rubber parts are also not included in the set. So remove everything carefully from your unit as you might have to reuse some parts for your rebuild. I contacted them about the wrong parts and they immediately sent me the correct parts by mail. Great customer services - I would order from them anytime again!

As I had never done a full rebuild I asked my Cadillac friend Lucky for help - knowing that he can repair almost everything, and that he had done this job during the full restoration of his awesome 58 Biarritz before.

He was so kind to offer his assistance and invited me to his fantastic work shop where he is restoring his cars.

So I carefully removed the whole unit from my car and visited Lucky´s workshop.

With his skills he managed to rebuild the whole unit within a couple of hours. As it turned out a bad O-ring caused fluid to leak into the booster.

Due to all the brake fluid the finish of the Bendix unit suffered a lot, and so I decided to strip everything on the outside down to bare metal to repaint it.

So I took everything apart once again to make sure to do it perfectly.

I ordered some great spray cans from Eastwood to get the perfect look to match its appearance to when it was new.

Originally the master cylinder was not painted at all - but left in bare cast metal. Of course it started to collect surface rust very quickly - even on new cars back in 1958.

The booster originally was painted in semi gloss black.

Eastwood has a product called "Brake Gray" which I used to emulate this look. It comes extremely close to bare metal, but of course the paint protects the metal from rust. This paint is also resistant against brake fluid. I first primered the master cylinder with self etching primer two times before two coats of brake gray were applied.

For the brake booster I ordered Eastwoods Chassis Black extreme primer and satin black paint - painting turned out really fine! See pictures below

To make bleeding brakes easier and a one person job I also ordered a set of speed bleeder screws. (SB3824-SS)

The unit still in the car - before removal

Removal has started

The unit out of the car - before rebuilding it.

Out of the car

In Lucky´s workshop with the rebuild kit I got from the USA

My friend Lucky at work

Lucky´s fantastic work shop

The Bendix master cylinder fully disassembled

Everything disassembled

This O-ring was leaking and caused the problem.

The new o-ring in place.

The vacuum cylinder

As you can see the paint suffered from the brake fluid - a repaint was necessary after the rebuild.

I started to wire brush the paint off - took it apart once again after this picture.

The master cylinder in primer.

After painting it with "Brake Gray" - great stuff.

The master cylinder with paint

The booster in bare metal before primer. I used Eastwood Extrem Chassis Black primer and paint.

In primer

Speed Bleeder screws

Speed Bleeder screws and bag

The new Speed Bleeder screw in place

The reassembled unit back in the car.

Outlook to the 2012 season - doing the first repairs 2012

The following work is planed for the next few months before the cars will be put back on the road in May 2012.

1971 Mark III

- new vinyl roof (the original one was damaged during transport and the insurance will pay for a new one)

1967 DeVille

- needs new front wheel bearings (I already have the spare parts)

- will try to find a rebuilt OEM Bendix master cylinder and vacuum booster. These are very difficult to find. Everybody seems to offer Delco Moraine parts only. I have replaced my original booster and master cylinder 2 years ago and I´m not quite happy with the power assist of the new units. It seems that the after market master cylinders from Delco have a smaller bore diameter and therefore you will have to depress the pedal with more force. There is a discussion going on on the topic of finding the correct booster and master cylinder in the CLC forum - check it out for more detail! If you know where I could find a correct Bendix booster and master cylinder or where I could get my original core rebuilt, please let me know!! The parts number for the Bendix Master Cylinder is #1489981 and for the Bendix booster it is: #1489071

- re-adjust the gear indicator as it's slightly out of line.

1967 Eldorado

- I will remove the starter motor and have it rebuilt - it sometimes is acting up

1958 Eldorado

- It needs some new front wheel bearings as well. I already bought the parts.

I will of course post the repair progress here on my website

A new garage?

The biggest planned project for 2012 will be to find a solution for my storage problem. I hope to be able to build another garage or to rent one. I will have to find a solution until the spring of 2012. I´m dreaming of building a building which can hold 8 Cadillacs, but I do not know yet if I will be able to afford it...

Car Shows

I hope to attend and visit the „Klassikwelt Bodensee“ from May 17th to 20th and of course the best meeting in Europe - the Cadillac BIG Meet August 25th to 26th. I will also hopefully make it to some local shows here in Austria.

As we had a dry winter day I took the cars out of the garage - they fired right up after some months of sleeping

The Mark III was moved to the back of the garage, so that I can start working on the other cars first

Little Elliot loves Daddy´s cars as well ;-)

1966 Cadillac Coupe deVille (16)

1967 Cadillac DeVille (54)

1967 Cadillac Eldorado (73)

1971 Lincoln Continental Mark III (24)

1974 Cadillac Coupe deVille (46)

1978 Cadillac Eldorado Biarritz (25)

1996 Buick Roadmaster (20)

Cadillac BIG Meet (2)

Car Shows (55)

Cruising (4)

CT6 (1)

For Sale (3)

Garage Stuff (32)

Pacer (1)

Restoration (140)

Various (55)

Video (20)

Website News (31)

- 6 way power seat

- 8-track

- 10 Ohm

- 429

- 1932

- 1957

- 1958

- 1958 Cadillac Eldorado Seville

- 1958 Cadillac Repair Tip

- 1959 Cadillac Eldorado Seville

- 1964

- 1965

- 1966

- 1966 Cadillac Coupe deVille

- 1966 Cadillac Repair Tips

- 1967

- 1967 Cadillac DeVille

- 1967 Cadillac Eldorado Repair Tip

- 1967 Cadillac Repair Tip

- 1967 Eldorado

- 1968

- 1970 Cadillac Eldorado

- 1971

- 1971 Lincoln Continental Mark III

- 1974

- 1974 Cadillac Coupe DeVille

- 1974 Cadillac Repair Tip

- 1976

- 1977

- 1978

- 1978 Cadillac Eldorado Biarritz

- 1978 Cadillac Repair Tip

- 1980 Cadillac Eldorado Biarritz

- 1996

- 2012

- 2014

- 2017

- 2018

- 2019

- 2022

- 2023

- 2025

- 3063206

- 7027235

- 7800483

- 7805675

- 7805676

- 12355706

- 17058531

- 17059968

- 17059969

- 22010515

- 22010661

- A.I.R

- A6

- AC

- AC Compressor

- AC Electrical Diagram

- ACC

- Accelerator Pump

- Accelorator pump

- Accident

- Actuators

- Adriatic Blue Metallic

- Ads

- Aftermovie

- Air Pump

- Aircondition

- AIRPUMP

- ALC

- Alternator

- AM

- AM-Transmitter

- Antenna

- Anti Rattle Clips

- Antique Gold

- Arizona Vintage Parts

- Arrival

- Article

- ASC

- Ash Tray removal

- ATC

- Atlantis Blue Firemist

- Austria

- Austro Classic

- Autolite SP-459

- Automatic Seat Back Release

- Award

- Banner

- Barn Find

- Battery

- Battery Tray

- Beach Race

- Bearing

- Bendix

- Biarritz

- Bigfoot

- Bill Hirsch Engine Enamel

- Bleeder Screws

- Bleeding

- Blower

- Bodywork

- Bolts

- Book

- Borg

- Brake Booster

- Brake Fluid

- Brake Gray

- Brakes

- Broken Bolt

- Brougham

- Bucket seats

- Buick

- Bumper End

- Bushings

- Cadillac

- Cadillac BIG Meet

- Cadillac BIG Meet

- Cadillac birthday cake

- Cadillac Blue

- Cadillac Color Selections Dealer Book

- Cadillac Coupe deVille

- Cadillac Dealer

- CADILLAC GRAND EUROPEAN

- Cadillac Meeting

- Cadillac Mini Meeting

- Camaro RS

- Caorle

- Car Show

- Carburetor

- Card

- Carpet

- Carter AFB

- Cavalry Twill Vinyl

- CB

- CBM

- CCCD

- Choke

- Christmas

- Citizens Band

- Classic Cadillac Club Deutschland

- Clay Towel

- Cleaning

- Clock

- Clockwork

- Clutch

- Clutch Coil

- Collector

- Colonial Yellow

- Color Coded Springs

- Commercial

- Compound

- Compressor

- Condenser

- Continental Mark III

- Control Head

- Conversion

- Convertible top

- Coolant

- Corona

- Cowl

- Cruise Control

- Cruising

- CT6

- CV Boots

- CV JOINTS

- D6230

- Dash Trim

- Decal Removal

- Decals

- Decoration

- Dehumidifier

- Delco Moraine

- Der Standard

- detailing

- Deville

- Diagnosis Chart

- Diagram

- Dial

- Digital Rotary Drum Clock

- Diner

- Disc Brakes

- Distributor

- Diverter Valve

- Door Jamb Switch

- Door Rubber Conduit

- Dornbirn

- Dot3

- Drive Shaft

- Driving tour

- Drum brakes

- Dry Ice Blasting

- Dry Ice Cleaning

- DVD

- Eastwood

- Eldorado

- Electric Choke Thermostat

- Electrical schematic

- Elvis

- Engine Bay

- Ep

- Epoxy floor

- Europe

- Evaporator

- Exide

- Factory Markings

- Fender Skirt

- Floor

- Flushing

- Flyer

- Foam

- For Sale

- Front AXLE

- Front brakes

- Front bumper filler

- Front Floor

- Front wheel bearing

- Fuel Filter

- Fuel Pump

- Fuel Sending Unit

- Fusible Link

- Garage

- Garage Cabinets

- Gasket

- GE

- Gear indicator

- General Time

- Glove box light

- Grand European

- H4

- Haus of Hot Rod

- Headlight Actuator

- Headlight doors

- Headlights

- Heater Core

- Heater Hose

- Heater Valve

- High Idle

- History

- Holley

- Honest John

- Hood

- Hood Emblem

- Hood Ornament

- Hose Clamp

- Hot Choke

- Hot Water Valve

- HotRod

- How to

- Hödlmayr

- Ignition Diagram

- Illuminated Entry

- John D‘Agostino

- John Foust

- Klassikwelt Bodensee

- Kremsmünster

- LaSalle

- Leather seats

- Light Switch

- Limited

- Lincoln

- Lincoln Mark III Repair Tip

- Low Mileage

- Magazine

- Marilyn Monroe

- Mark III

- Master Cylinder

- Master Switch

- Master Vacuum Switch

- Media Blasting

- Meeting

- Meguiras

- MK II

- Mobile

- Model

- Moldings

- Mom

- Mopar Nationals

- Mostkost Kustom

- Movie

- Munich

- Neon

- NOS

- Oberösterreicher des Tages

- oilchange

- ORF

- Overspray

- Pacer

- Paint

- Paint correction

- Paintjob

- Part Number

- Parts

- Patch Panel

- Perfect Circle

- Permabag

- Persian Lime

- Photo shooting

- Photoshooting

- Pictures

- PinUp

- POA Valve

- Power Antenna

- Power Servo

- Power Vent Windows

- Power Window

- Printed Circuit Board

- Programmer

- Pulley

- Quadrajet

- Quarter Panel

- Quartz Conversion

- R134

- Radiator

- Radio

- Rattle

- Rear brakes

- Rebuild

- Recalibrate

- RediRad

- Reed Switch

- Relais

- Relaunch

- Removing Overspray

- Repaint

- Repair

- Restoration

- RIP

- Roadhouse

- Roadmaster

- Rochester

- Rocker Arm Cover

- Rocker Panel Extension Clips

- Rostio

- Rotary Valve

- Rotterdam

- Rupes

- Rust removal

- Rust removal gel

- Sabre Wheels

- Sand Blasting

- Sandblasting

- Screed

- Season Greetings

- Seasons Greetings

- Seat Back Locks

- Seat Padding

- Seat Transmission

- See through ornament

- Self adjusters

- Self Starter

- Sepp's Garage

- Seville

- Sheetmetal

- Shocks

- shop manual

- short

- Sign

- Solenoid

- Spark Plug Wire Routing

- Speakers

- Special Award

- Speed Bleeder Screws

- Splash Guard

- Starter Diagram

- Starter Motor

- Steering Column

- Storage

- suction throttling valve

- sunroof

- suspension

- Swirl Mark removal

- Switzerland

- T3

- Taillight Cover

- Texan´s Choice Award

- Thermostat

- Tilt and Telescope

- Time capsule

- Tomsclub

- Torque Specifications

- Tower Hose Clamp

- Towtruck

- Trailer

- Transducer

- Transmission

- transmission control selector

- transmission control selector indicator light

- transmission shift indicator

- Treadle Vac

- Treffen

- Tri-Band

- Troubleshooting

- Trunk Cardboard Kit

- Trunk lid

- Trunk lining

- Trunk to bumper cover

- Turn Signal Switch

- TV

- Typisierung

- Ultimate Garage

- Underbody

- Undercarriage

- Undercoating

- Undercoating Removal

- Vacuum Booster

- Vacuum diagram

- Vacuum hoses

- Vacuum Master Switch

- Vacuum Schematic

- Vacuum Valve

- Valve Cover

- Various

- Vent Window Switch

- Vibration

- Vibrator

- Vicodec roof

- Video

- Vinegar

- Vinyl Roof

- Visitor

- Washer Fluid Float

- Washer Fluid Low Level Indicator

- Water Pump

- Wax

- Weatherstripping

- Website News

- Westclox

- Wheel Bearings

- Wheel Housing

- Wiesbaden

- Windlace

- Winter

- Wiring

- Wiring Diagram

- Wonderbar

- Workbench

- Zurzach

GERALD´S CADILLACS - NEWS

GERALD´S CADILLACS - NEWS